Operators achieve precise and safe control of the Dredger Winch through advanced integration of PLCs, sensors, and hydraulic systems. Real-time monitoring, predictive maintenance, and automation enhance efficiency and safety.

| Aspect | Summary |

|---|---|

| Precision Control | PLCs and sensors support accurate load handling and minimize human error. |

| Safety Features & Automation | Automated overload protection and emergency stops reduce operator risk during winch operation. |

Key Takeaways

- Dredger winch control systems use PLCs, sensors, and hydraulic or electric components to provide precise, safe, and efficient operation.

- Operators can control winches manually or remotely through user-friendly panels and wireless remotes, improving safety and flexibility.

- Advanced automation and real-time monitoring reduce human error, enhance safety, and boost productivity during dredging operations.

Dredger Winch Control System Components

Control Panels and Interfaces

Operators interact with dredger winch systems through a variety of control panels and interfaces. These interfaces provide centralized access to operational controls, monitoring, and safety features. The following table outlines the main types of control panels and their distinct functionalities:

| Control Panel / Interface Type | Description & Features | Functionality Differences |

|---|---|---|

| On-board PLC-based Graphical Operator Interface | Industrial computer workstation with touch screen; allows setting parameters, automation selections, alarm management, and manual/automatic control of winches and ladder. | Supports manual and automatic modes; touch screen slider controls for speeds; integrated with automation and monitoring systems; interlocks and safety features included. |

| Hand-held Gamepad Controller | Portable controller for manual winch and ladder operation; alternative to touch screen. | Enables manual fine control, especially useful for anchor setting; complements graphical interface. |

| Shore-mounted Control Panel | Remote control panel with switches and indicators; allows operation from shore. | Provides remote operation capability; includes power switches, pump controls, and alarms; may have selector switches for hand/automatic modes. |

| Radio Remote Hand-held Panel | Wireless remote control with basic operational controls and indicators. | Offers mobility and remote operation; typically includes power switches, pump controls, and warning indicators. |

Tip: Modern control panels often include touch screens and wireless remotes, enabling operators to manage winch operations from multiple locations for enhanced safety and flexibility.

Programmable Logic Controllers (PLCs)

PLCs serve as the brain of the dredger winch control system. They continuously monitor hydraulic pressures and control winch speeds to maintain proper cable tensions. Operators use touch screens and handheld controllers to switch between manual and automatic modes. PLC logic incorporates safety interlocks, pressure limits, alarms, and emergency backup functions. These features allow quick release of winch brakes and adjustment of mooring modes during hazardous situations. PLCs also optimize winch swing speeds based on production parameters, coordinating winch operations with other dredge systems such as ladder control and cutter depth. Remote monitoring and data logging support operational oversight and reporting. The integration of PLCs ensures efficient, safe, and optimized automation for dredger winch operations.

Sensors and Feedback Devices

Sensors and feedback devices play a critical role in monitoring load and position on dredger winches. These components provide real-time data to the control system, enhancing both accuracy and safety.

- Hydraulic spud systems use hydraulic cylinders and power units for precise spud positioning and load management.

- Load sensors integrated into the hydraulic system monitor anchoring forces.

- Position feedback devices, such as encoders and displacement sensors, enable millimeter-level accuracy in spud placement.

- Digital control interfaces track operational parameters like anchoring load distribution, hydraulic pressure, temperature, spud penetration depth, and soil resistance.

- Load limiting systems and variable speed controls rely on sensors to detect overload and adjust operation.

Encoders attached to winch motors deliver real-time speed and position feedback, allowing the drive system to control winch motor operations precisely. The PLC receives encoder signals and uses trigonometric algorithms to calculate depth information, improving operational accuracy. Variable Frequency Drives (VFDs) integrated with feedback devices ensure smooth lifting of drag arms, boosting productivity. Brake control routines test torque before releasing brakes, preventing accidental releases and ensuring safe load handling.

Actuators and Motors

Actuators and motors convert energy into mechanical movement, powering the dredger winch. Hydraulic cylinders and motors transform hydraulic pressure into linear or rotational motion. Hydraulic pumps supply power for the entire system, while control valves regulate pressure, flow, and direction. The following table summarizes key components and their performance characteristics:

| Component Type | Description | Performance Characteristics / Features |

|---|---|---|

| Actuators | Hydraulic cylinders and hydraulic motors convert hydraulic pressure into mechanical energy. | Enable linear or rotational movement of the winch load. |

| Power Supply Components | Hydraulic pumps (gear, vane, plunger, screw pumps) convert mechanical energy to hydraulic energy. | Provide power for the entire hydraulic system. |

| Control Components | Hydraulic valves (pressure, flow, directional control valves) regulate hydraulic flow. | Control pressure, flow, and direction; include safety and regulating valves. |

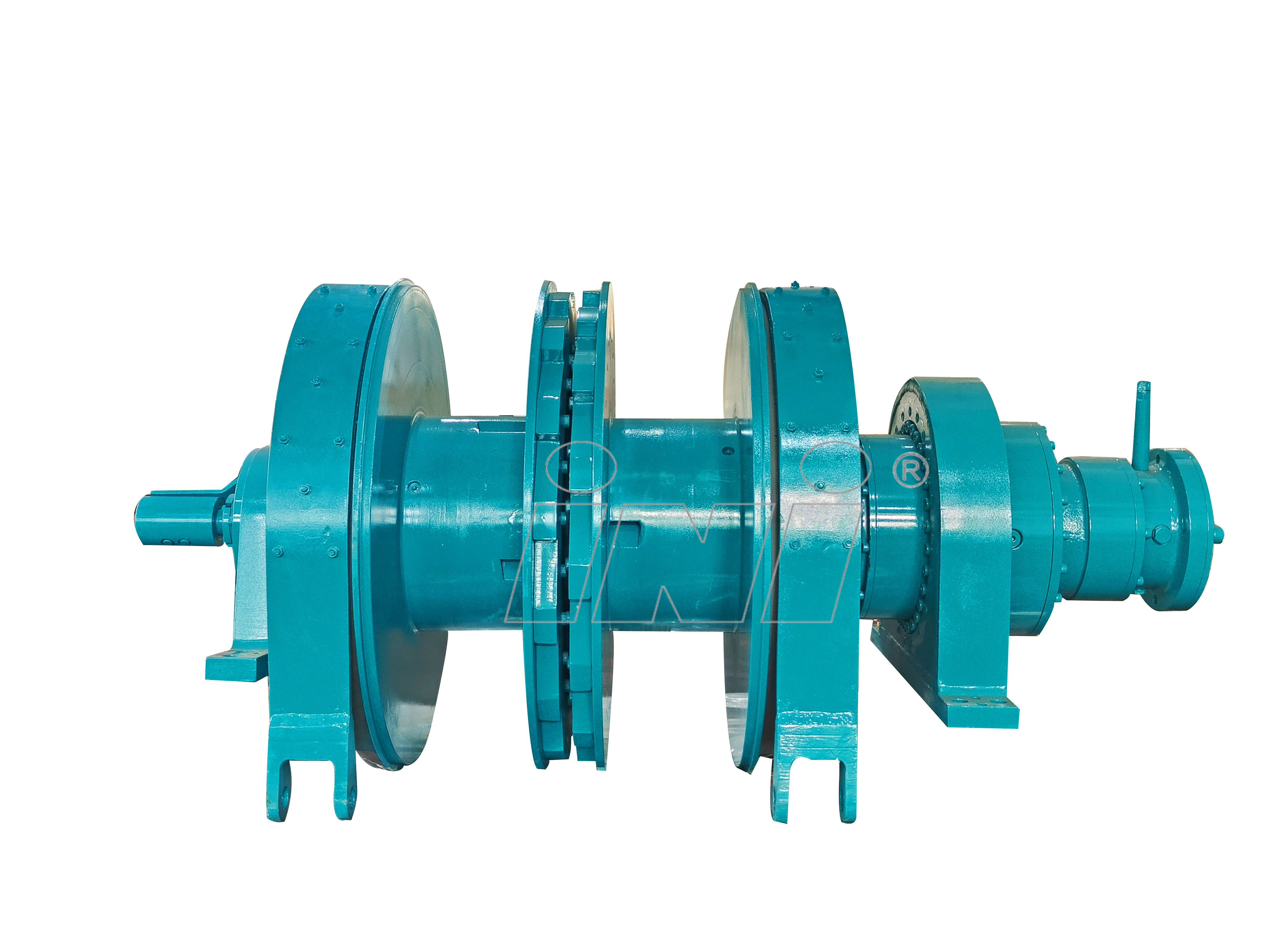

| Winch Characteristics | Small size, lightweight, strong, wear-resistant, anti-corrosive, safe, convenient, easy to maintain. | Stepless speed adjustment within a rope speed range; manual stop pins. |

| Hydraulic Oil | Working medium transferring energy in the hydraulic system. | Various types including mineral oils, emulsions, synthetic oils. |

Hydraulic actuators excel in providing precise torque at low speeds, which is essential for heavy-duty dredging. Electric actuators offer low energy consumption, minimal noise, and eliminate hydraulic fluid leaks, enhancing environmental safety and reducing maintenance complexity.

Hydraulic and Electric Winch Types

Dredger winch systems utilize both hydraulic and electric winches, each with unique control system integration and operational characteristics. The table below compares these types:

| Aspect | Electric Winch Control System | Hydraulic Winch Control System |

|---|---|---|

| Control Type | Electrically controlled; operated via wired/wireless remotes or manual switches | Hydraulically actuated; requires control valves and fluid flow management |

| Operation Requirement | Can be operated remotely with simple on/off or variable speed controls | Often requires vehicle engine running for operation |

| Control Complexity | Simpler installation and control | More complex integration with hydraulic valves and reservoirs |

| Precision & Automation | Variable speed available for precision control; user-friendly | Smoother, more precise control; can be automated depending on hydraulic system |

Hydraulic winches deliver high power and adaptability, making them suitable for heavy-duty dredging. They quickly adjust to different environments and offer simple operation for lifting and lowering materials. Electric winches provide moderate power and are ideal for lighter applications, with remote operation enhancing operator safety. Both types support remote control, allowing operators to manage winch operations from a safe distance.

Note: Regular maintenance, including inspections, lubrication, and component replacement, is essential for long-term reliability and safety of both hydraulic and electric winch systems.

Dredger Winch Operation and Automation

Manual and Automated Control Methods

Operators manage Dredger Winch systems using both manual and automated control methods. Manual operation relies on push-button controls located on remote panels, allowing functions such as forward, reverse, stop, raise, lower, and manual override. Automated control methods include remote positioning systems, which enable operators to control winches from shore using master control panels. The integration of manual and automated capabilities within the control panel ensures precise and flexible operation.

- Manual push-button controls provide tactile feedback and allow for direct intervention.

- Automated systems utilize remote control positioning, supporting efficient and safe operation from a distance.

- Control panels combine both approaches, giving operators the ability to switch between manual and automated modes as needed.

Operators benefit from the flexibility to choose the most suitable method based on operational requirements and environmental conditions.

Remote and Local Operation

Dredger Winch control systems support both remote and local operation. Remote operation leverages technologies such as remote I/O modules, intrinsically safe field communication, and flexible fieldbus systems. These technologies enable decentralized automation and reliable control in hazardous or remote environments. Physical protections, including control cabinet guards, maintain high information security and prevent unauthorized access.

Local operation allows operators to interact directly with control panels on the vessel. Remote systems enhance safety by enabling operators to control winches from a secure location, reducing exposure to noise, heat, and hydraulic leaks. Compact control cabinets and secure communication channels ensure rugged and reliable signal transmission.

Operators can transition seamlessly between local and remote operation, optimizing workflow and maintaining safety standards.

Feedback Loops and Real-Time Monitoring

Feedback loops play a vital role in real-time monitoring of Dredger Winch performance. These systems track critical parameters such as pump speed, output pressure, slurry density, flow velocity, cutterhead torque, RPM, and positional accuracy via GPS. Automated feedback loops use this data to reduce pump overload risk, optimize solids concentration, and prevent pipeline blockages.

Operators rely on real-time data from load cells, running line tension sensors, and alarms linked to high or low setpoints. PLCs and HMIs facilitate continuous data logging for historical and trending analysis. Off-site monitoring capabilities allow supervisors to oversee operations remotely. Environmental data, including water quality, current profiles, wave height, and meteorological conditions, further support compliance and operational safety.

Tip: Real-time monitoring and feedback loops ensure consistent output, improve energy efficiency, and help operators respond quickly to changing conditions.

Safety Features and Emergency Procedures

Modern Dredger Winch systems incorporate advanced safety mechanisms to protect operators and equipment. Automatic overload protection, emergency stops, and anti-snagging systems minimize exposure to hazardous conditions. Automation features such as automated rope spooling and precision tension control reduce manual intervention and human error.

Hydraulic winches use proportional control valves, closed-loop feedback, and programmable logic controllers to enhance operational control and efficiency. Sensor technologies combined with IoT connectivity enable predictive maintenance, reducing downtime and improving safety. Operators can activate fail-safe protocols and manual overrides to maintain continuity in case of signal loss or unexpected events.

The transition from manual to automated control modes significantly improves safety and efficiency. Operators experience less fatigue, maintain precise control, and avoid direct exposure to dangerous environments.

| Aspect | Manual Winches (Obsolete) | Hydraulic Winches (Preferred) |

|---|---|---|

| Control Method | Physical levers and foot pedals requiring significant effort | Hydraulic powered with proportional electronic controls |

| Operator Effort | High physical effort leading to fatigue | Low physical effort, reducing operator fatigue |

| Precision | Possible but small frequent movements are tiring | Precise feathering for small adjustments maintaining uniform flow |

| Safety | Operator exposed to noise, heat, and potential hydraulic leaks | Operator controls winch remotely from cab, reducing exposure to hazards |

| Production Efficiency | Decreases as operator tires | Increased due to ease of operation and precise control |

| Maintenance and Reliability | Mechanical, simpler but physically demanding | Requires hydraulic maintenance but improves operational control and safety |

| Additional Features | N/A | Pressure gauges for linepull monitoring, overload protection, and ease of operation |

Typical Operational Sequence

The operational sequence for a Dredger Winch follows a structured process to ensure safety and efficiency:

- Start the engine and allow it to idle until water temperature, oil temperature, and oil pressure reach specified levels.

- Turn on the power supply switch on the control cabinet before activating the sand pump.

- Lower the ladder winch, ladder, and suction pipe to submerge the cutterhead; start the flushing pump.

- Engage the gearbox and sand pump using the control panel switch; gradually increase engine speed to the specified rpm.

- Once water is drawn and the discharge pipe functions properly, activate the cutterhead for production using lateral movement.

- During operation, monitor engine conditions by checking for unusual smells, noises, instrument readings, hydraulic oil leaks, cooling water leaks, and vibrations.

- To stop production, raise the ladder winch to lift the cutterhead from the sand layer.

- Continue pumping water to flush sediment from the discharge pipeline.

- Reduce engine speed to stop the sand pump.

- Lift the dredger's ladder above water level and secure it with safety measures.

- Before departure, check and close seabed and other valves, disconnect power, and close windows and doors.

Operators coordinate with automated systems using unified interfaces that provide real-time data, alerts, and logs. Wireless remote controls enable precise positioning and smooth barge movement. Adaptive logic and sensor feedback maintain optimal winch and dredging parameters automatically. Ergonomic HMIs offer intuitive control environments, while fail-safe protocols and manual overrides ensure operational safety and continuity.

Automation strategies address operational challenges by employing synchronized multi-motor control, fuzzy PI controllers, and dynamic leveling algorithms. These approaches enhance robustness, maintain stable motion during complex phases, and ensure safety through effective disturbance rejection and overload management.

Note: Operators should remain vigilant during each phase of the operational sequence, using both manual and automated controls to maintain safety and productivity.

Operators achieve greater efficiency and safety with Dredger Winch control systems that combine automation, real-time monitoring, and user-friendly interfaces.

- Automatic swing speed control, GPS tracking, and programmable logic controllers enhance precision and safety.

- Digitalization and remote diagnostics reduce human error, increase productivity, and minimize operational risks.

FAQ

How does a PLC improve dredger winch safety?

A PLC monitors system parameters, enforces safety interlocks, and triggers emergency stops. Operators rely on PLCs to prevent overloads and ensure safe, reliable winch operation.

Can operators control the winch remotely?

Yes. Operators use wireless remotes or shore-based panels for remote control. This feature increases safety and flexibility during dredging operations.

What maintenance does a dredger winch control system require?

Operators perform regular inspections, lubrication, and sensor checks. They replace worn components as needed. Routine maintenance ensures reliable performance and extends equipment lifespan.

Post time: Aug-31-2025