Ama-opharetha afinyelela ukulawula okunembile nokuphephile kwe-Dredger Winch ngokuhlanganiswa okuthuthukile kwama-PLC, izinzwa, kanye nezinhlelo ezisebenza ngamanzi. Ukuqapha kwesikhathi sangempela, ukunakekelwa okubikezelwayo, kanye nokuzishintshanisa kuthuthukisa ukusebenza kahle nokuphepha.

| Isici | Isifinyezo |

|---|---|

| Ukulawula Ukunemba | Ama-PLC nezinzwa zisekela ukuphathwa komthwalo okunembile futhi zinciphisa iphutha lomuntu. |

| Izici Zokuphepha Nokuzenzakalela | Ukuvikelwa kokulayisha ngokweqile okuzenzakalelayo kanye nokuma kwezimo eziphuthumayo kunciphisa ubungozi bomsebenzisi ngesikhathi sokusebenza kwewintshi. |

Okuthathwayo Okubalulekile

- Amasistimu okulawula amawintshi e-Dredger asebenzisa ama-PLC, izinzwa, kanyeizingxenye ze-hydraulic noma zikagesiukuhlinzeka ngokusebenza okunembayo, okuphephile, nokusebenza kahle.

- Abasebenzisi bangakwazi ukulawula amawintshi ngokuzenzela noma bekude ngamaphaneli asebenziseka kalula nezilawuli kude ezingenantambo, ukuthuthukisa ukuphepha nokuvumelana nezimo.

- I-automation ethuthukisiwe nokuqapha ngesikhathi sangempela kunciphisa amaphutha abantu,thuthukisa ukuphepha, futhi kukhuphule ukukhiqiza ngesikhathi sokusebenza kwe-dredging.

Izingxenye Zesistimu Yokulawula I-Dredger Winch

Control Panel kanye Interfaces

Ama-opharetha asebenzisana nezinhlelo zewintshi ze-dredger ngokusebenzisa amaphaneli okulawula ahlukahlukene kanye nezindawo zokusebenzelana. Lezi zixhumanisi zinikeza ukufinyelela okumaphakathi kuzilawuli zokusebenza, ukuqapha, nezici zokuphepha. Ithebula elilandelayo libonisa izinhlobo eziyinhloko zamaphaneli okulawula kanye nokusebenza kwawo okuhlukile:

| Iphaneli yokulawula / Uhlobo lwesixhumi esibonakalayo | Incazelo nezici | Umehluko Wokusebenza |

|---|---|---|

| I-PLC-based Graphical Operator Interface esekwe ebhodini | Indawo yokusebenzela yekhompyutha yezimboni enesikrini sokuthinta; ivumela ukusetha amapharamitha, ukukhetha okuzenzakalelayo, ukuphathwa kwe-alamu, nokulawula okwenziwa ngesandla/okuzenzakalelayo kwamawintshi kanye nesitebhisi. | Isekela izindlela zemanuwali nezizenzakalelayo; izilawuli zesilayidi sesikrini sokuthinta ukuze uthole isivinini; kuhlanganiswe nezinhlelo ezizenzakalelayo nezokuqapha; okuhlanganisiwe nezici zokuphepha ezifakiwe. |

| Isilawuli se-Gamepad esibanjwa ngesandla | Isilawuli esiphathekayo sokusebenza kwewintshi kanye nesitebhisi ngesandla; okunye ukuya kwesikrini sokuthinta. | Inika amandla ukulawula okuhle okwenziwa ngesandla, ikakhulukazi okuwusizo ekusethweni kwehange; igcwalisa isikhombimsebenzisi sesithombe. |

| Iphaneli yokulawula ebekwe ogwini | Iphaneli yokulawula kude enamaswishi nezinkomba; ivumela ukusebenza kusuka ogwini. | Inikeza amandla okusebenza okude; kufaka phakathi ukushintsha kwamandla, izilawuli zephampu, nama-alamu; ingase ibe nokushintsha kwesikhethi kumamodi esandla/azenzakalelayo. |

| Iphaneli ephathwa ngesandla yesilawuli kude somsakazo | Isilawuli kude esingenantambo esinezilawuli zokusebenza eziyisisekelo nezinkomba. | Inikeza ukuhamba nokusebenza okukude; ngokuvamile kufaka phakathi ukushintsha kwamandla, izilawuli zephampu, nezinkomba eziyisixwayiso. |

Ithiphu: Amaphaneli okulawula esimanje ngokuvamile ahlanganisa izikrini zokuthinta nezilawuli kude ezingenantambo, okuvumela opharetha ukuthi balawule ukusebenza kwamawintshi ezindaweni eziningi ukuze kuthuthukiswe ukuphepha nokuvumelana nezimo.

I-Programmable Logic Controllers (PLCs)

Ama-PLC asebenza njengobuchopho bohlelo lokulawula i-dredger winch. Bahlale beqapha ukucindezela kwe-hydraulic futhi balawule isivinini sokuwina ukuze kugcinwe ukungezwani kwekhebula okufanele. Ama-opharetha asebenzisa izikrini zokuthinta nezilawuli eziphathwa ngesandla ukushintsha phakathi kwamamodi okwenziwa ngesandla kanye ne-othomathikhi. Ukuqonda kwe-PLC kuhlanganisa izikhiya zokuphepha, imikhawulo yengcindezi, ama-alamu, nemisebenzi eyisipele yezimo eziphuthumayo. Lezi zici zivumela ukukhishwa okusheshayo kwamabhuleki e-winch kanye nokulungiswa kwamamodi okuhambisa phakathi nezimo eziyingozi. Ama-PLC aphinde andise isivinini se-winch swing ngokusekelwe kumingcele yokukhiqiza, ukuxhumanisa ukusebenza kwe-winch nezinye izinhlelo ze-dredge ezifana nokulawula iladi nokujula kokusika. Ukuqapha okukude nokuloga kwedatha kusekela ukwenganyelwa kokusebenza nokubika. Ukuhlanganiswa kwama-PLC kuqinisekisa ukusebenza kahle, okuphephile, futhi okuzenzakalelayo okuzenzakalelayo kokusebenza kwe-dredger winch.

Izinzwa kanye namadivayisi empendulo

Izinzwa namadivayisi empendulo adlala indima ebalulekile ekuqapheni umthwalo kanye nokuma kumawintshi e-dredger. Lezi zingxenye zinikeza idatha yesikhathi sangempela ohlelweni lokulawula, okuthuthukisa kokubili ukunemba nokuphepha.

- Amasistimu we-hydraulic spud asebenzisa amasilinda asebenza ngamanzi kanye namayunithi wamandla ukuze amise kahle i-spud nokuphathwa komthwalo.

- Izinzwa zokulayisha ezihlanganiswe ohlelweni lwe-hydraulic ziqapha amandla okubamba.

- Amadivayisi wempendulo yesikhundla, njengezifaki khodi nezinzwa zokuthutha, anika amandla ukunemba kweleveli ye-millimeter ekubekweni kwe-spud.

- Izixhumi ezibonakalayo zokulawula idijithali zilandelela amapharamitha okusebenza njengokusabalaliswa komthwalo okubamba ihange, umfutho we-hydraulic, izinga lokushisa, ukujula kokungena kwe-spud, nokumelana nomhlabathi.

- Amasistimu okukhawulela ukulayisha kanye nezilawuli zesivinini esiguquguqukayo zithembele kuzinzwa ukuze zithole ukugcwala kakhulu futhi zilungise ukusebenza.

Izifaki khodi ezinamathiselwe kuma-winch motors ziletha isivinini sesikhathi sangempela kanye nempendulo yesikhundla, okuvumela isistimu yokushayela ukuthi ilawule ukusebenza kwe-winch motor ngokunembile. I-PLC ithola amasiginali wokufaka ikhodi futhi isebenzisa ama-algorithms e-trigonometric ukubala ulwazi olujulile, ithuthukise ukunemba kokusebenza. I-Variable Frequency Drives (VFDs) ehlanganiswe namadivayisi empendulo aqinisekisa ukuphakanyiswa okushelelayo kwezingalo zokuhudula, kuthuthukisa ukukhiqiza. Izindlela zokulawula amabhuleki zihlola i-torque ngaphambi kokukhulula amabhuleki, ukuvimbela ukukhishwa ngengozi kanye nokuqinisekisa ukuphatha okuphephile komthwalo.

Ama-Actuator nama-Motor

Ama-Actuator namamotho aguqula amandla abe ukunyakaza kwemishini, anike amandla i-dredger winch. Amasilinda we-hydraulic namamotho aguqula ingcindezi ye-hydraulic ibe ukunyakaza okuqondile noma okujikelezayo. Amaphampu e-hydraulic ahlinzeka ngamandla kulo lonke uhlelo, kuyilapho ama-valve okulawula elawula ingcindezi, ukugeleza, kanye nendlela. Ithebula elilandelayo lifinyeza izingxenye ezibalulekile nezici zazo zokusebenza:

| Uhlobo Lwengxenye | Incazelo | Izimpawu Zokusebenza / Izici |

|---|---|---|

| Ama-Actuator | Amasilinda we-hydraulic kanye nama-hydraulic motors aguqula ingcindezi ye-hydraulic ibe amandla emishini. | Nika amandla ukunyakaza komugqa noma ukuzungezisa komthwalo wewintshi. |

| Izingxenye Zokuhlinzeka Ngamandla | Amaphampu we-Hydraulic(igiya, i-vane, i-plunger, amaphampu ngezikulufu) guqula amandla omshini abe amandla asebenza ngamanzi. | Nikeza amandla kulo lonke uhlelo lwe-hydraulic. |

| Izingxenye Zokulawula | Ama-valve e-hydraulic (ingcindezi, ukugeleza, ama-valve okulawula isiqondiso) alawula ukugeleza kwamanzi. | Lawula ingcindezi, ukugeleza, kanye nendlela; zihlanganisa ukuphepha kanye nama-valve okulawula. |

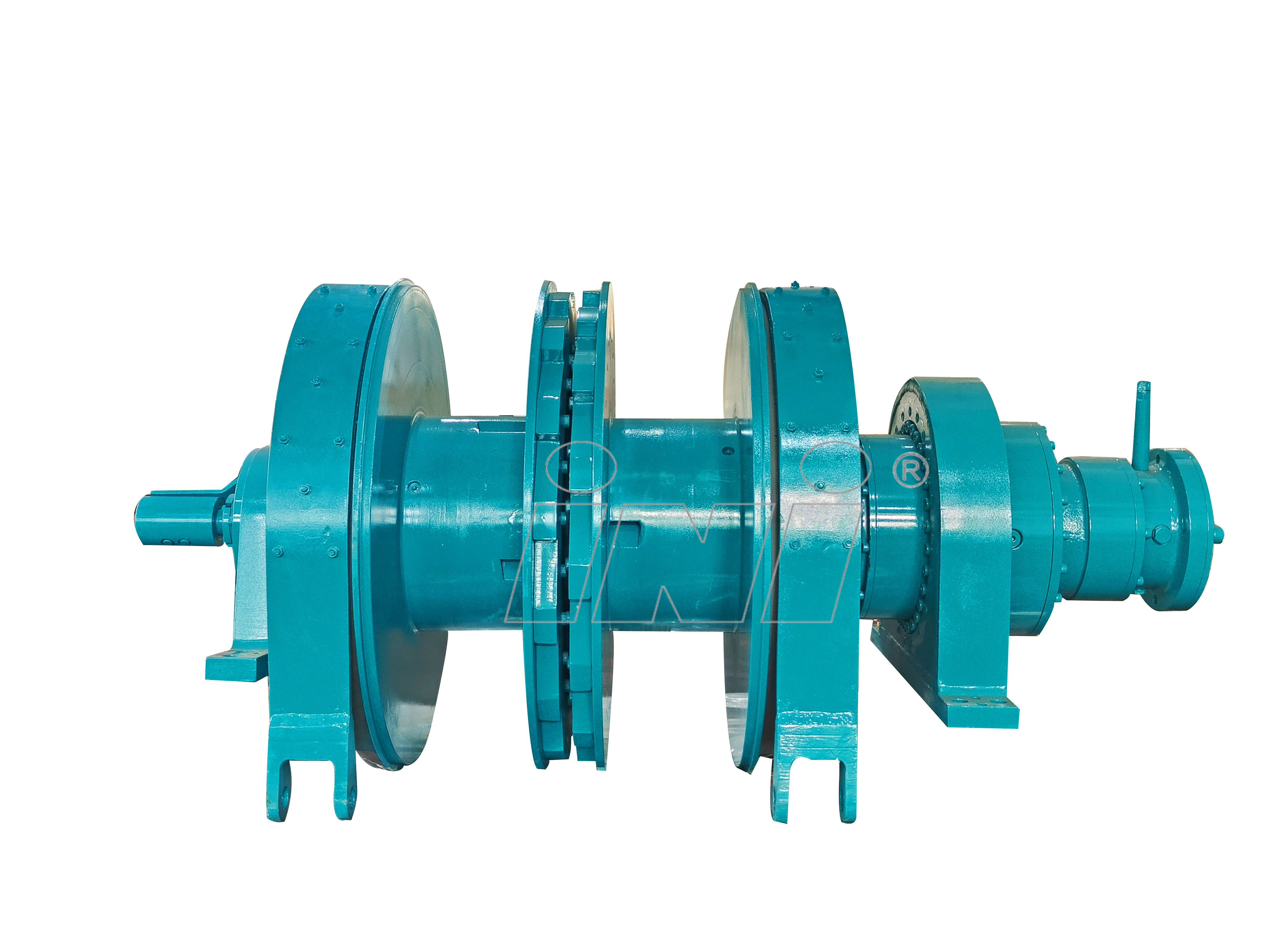

| Izici zeWinch | Usayizi omncane, ongasindi, uqinile, awugugi, awugqwali, uphephile, ulungile, kulula ukuwunakekela. | Ukulungiswa kwesivinini esingenasinyathelo ngaphakathi kwebanga lesivinini sezintambo; izikhonkwane zokumisa manual. |

| Amafutha E-Hydraulic | Amandla okudlulisa aphakathi nendawo ohlelweni lwe-hydraulic. | Izinhlobo ezahlukahlukene ezihlanganisa uwoyela wamaminerali, ama-emulsions, uwoyela wokwenziwa. |

Ama-actuator e-hydraulic ahamba phambili ekunikezeni i-torque enembile ngesivinini esiphansi, okubalulekile ekudonseni umsebenzi osindayo. Ama-actuator kagesi anikeza ukusetshenziswa kwamandla okuphansi, umsindo omncane, futhi aqede ukuvuza koketshezi olunamanzi, athuthukisa ukuphepha kwemvelo futhi anciphise ubunkimbinkimbi bokulondolozwa.

Izinhlobo ze-Hydraulic kanye neWinch kagesi

Ama-winch e-Dredger asebenzisa amawintshi womabili amanzi kanye nakagesi, ngalinye linokuhlanganiswa kwesistimu yokulawula eyingqayizivele nezici zokusebenza. Ithebula elingezansi liqhathanisa lezi zinhlobo:

| Isici | Isistimu Yokulawula Iwintshi Kagesi | IHydraulic Winch Control System |

|---|---|---|

| Uhlobo Lokulawula | Ilawulwa ngogesi; isetshenziswa ngezilawuli kude ezinezintambo/ ezingenazintambo noma ngokushintsha okwenziwa ngesandla | Isebenza nge-hydraulic; idinga ama-valve okulawula kanye nokuphathwa kokugeleza kwamanzi |

| Imfuneko Yokusebenza | Ingaqhutshwa ukude ngezilawuli ezilula zokuvula/ukuvala noma eziguquguqukayo | Ngokuvamile kudinga ukuthi injini yemoto isebenze ukuze isebenze |

| Lawula Ukuxaka | Ukufakwa nokulawula okulula | Ukuhlanganiswa okuyinkimbinkimbi kakhulu nama-valve we-hydraulic nama-reservoirs |

| Ukunemba & Okuzenzakalelayo | Isivinini esiguquguqukayo esitholakalayo sokulawula ukunemba; kuyasebenziseka | Ukulawula okubushelelezi, okunembe kakhudlwana; kungenziwa ngokuzenzakalelayo kuye ngohlelo lwe-hydraulic |

Amawintshi e-Hydraulic aletha amandla aphezulu nokuvumelana nezimo, okuwenza afanelekele ukudonsa kanzima. Bazivumelanisa ngokushesha nezimo ezahlukahlukene futhi banikeze ukusebenza okulula kokuphakamisa nokwehlisa izinto. Amawintshi kagesi anikeza amandla amaphakathi futhi alungele izinhlelo zokusebenza ezilula, ngokusebenza okukude okuthuthukisa ukuphepha komsebenzisi. Zombili izinhlobo zisekela isilawuli kude, okuvumela opharetha ukuthi baphathe imisebenzi yewintshi bekude nebanga eliphephile.

Qaphela: Ukunakekelwa okuvamile, okuhlanganisa ukuhlolwa, ukugcotshwa, nokushintshwa kwengxenye, kubalulekile ekuthembekeni kwesikhathi eside nokuphepha kwakho kokubili amasistimu ewintshi esebenza ngogesi kanye nekagesi.

I-Dredger Winch Operation kanye ne-Automation

Izindlela zokulawula ezenziwa ngesandla kanye nezizenzakalelayo

Opharetha baphatha amasistimu e-Dredger Winch besebenzisa izindlela zokulawula ezenziwa ngesandla nezizenzakalelayo. Ukusebenza mathupha kuncike kuzilawuli zenkinobho yokucindezela ezitholakala kumaphaneli akude, okuvumela imisebenzi efana nokuya phambili, ukuhlehla, ukuma, ukukhuphula, ukwehlisa, nokubhala ngaphezulu mathupha. Izindlela zokulawula ezizenzakalelayo zihlanganisa izinhlelo zokubeka kude, ezivumela opharetha ukuthi balawule amawintshi ukusuka ogwini besebenzisa amaphaneli okulawula ayinhloko. Ukuhlanganiswa kwamakhono okwenziwa ngesandla nazenzakalelayo ngaphakathi kwephaneli yokulawula kuqinisekisa ukusebenza okunembile nokuguquguqukayo.

- Izilawuli zenkinobho yokusunduza mathupha zinikeza impendulo ethintekayo futhi zivumela ukungenelela okuqondile.

- Amasistimu azenzakalelayo asebenzisa ukuma kwesilawuli kude, asekela ukusebenza okuphumelelayo nokuphephile ukusuka kude.

- Amaphaneli okulawula ahlanganisa zombili izindlela, anikeze opharetha ikhono lokushintsha phakathi kwezindlela ezenziwa ngesandla nezizenzakalelayo njengoba kudingeka.

Ama-opharetha ayazuza ekuguquguqukeni kokukhetha indlela efaneleke kakhulu ngokusekelwe ezidingweni zokusebenza nezimo zemvelo.

Ukusebenza okukude nokwasendaweni

Izinhlelo zokulawula i-Dredger Winch zisekela kokubili ukusebenza okukude nokwasendaweni. Ukusebenza kwesilawuli kude kusebenzisa ubuchwepheshe obufana namamojula e-I/O akude, ukuxhumana kwenkundla okuphephile ngaphakathi, kanye nezinhlelo zebhasi yasensimini eziguquguqukayo. Lobu buchwepheshe bunika amandla i-automation ehlukanisiwe kanye nokulawula okuthembekile ezindaweni eziyingozi noma ezikude. Ukuvikela okungokwenyama, okuhlanganisa onogada bekhabhinethi yokulawula, ukugcina ukuphepha kolwazi oluphezulu futhi kuvimbele ukufinyelela okungagunyaziwe.

Ukusebenza kwendawo kuvumela opharetha ukuthi bahlanganyele ngokuqondile namaphaneli okulawula emkhunjini. Amasistimu akude athuthukisa ukuphepha ngokuvumela opharetha ukuthi balawule amawintshi endaweni evikelekile, behlise ukuchayeka emsindweni, ukushisa, nokuvuza kwe-hydraulic. Amakhabethe okulawula okuqinile kanye neziteshi zokuxhumana ezivikelekile ziqinisekisa ukudluliswa kwesignali okuqinile nokuthembekile.

Ama-opharetha angashintsha kalula phakathi kokusebenza kwendawo nokukude, athuthukise ukuhamba komsebenzi futhi agcine amazinga okuphepha.

Izihibe zempendulo kanye nokuqapha kwesikhathi sangempela

Izihibe zempendulo zidlala indima ebalulekile ekuqaphelweni kwesikhathi sangempela kokusebenza kwe-Dredger Winch. Lawa masistimu alandelela amapharamitha abalulekile afana nesivinini sepompo, ukucindezela kokuphumayo, ukuminyana okunodaka, isivinini sokugeleza, itorque ye-cutterhead, i-RPM, kanye nokunemba kwendawo nge-GPS. Izihibe zempendulo ezizenzakalelayo zisebenzisa le datha ukunciphisa ingcuphe yokugcwala kwephampu, kuthuthukise ukugxila kokuqinile, futhi kuvimbele ukuvinjwa kwamapayipi.

Ama-opharetha athembele kudatha yesikhathi sangempela esuka kumaseli okulayisha, izinzwa zomugqa ogijimayo, nama-alamu axhunywe kuma-setpoints aphezulu noma aphansi. Ama-PLC nama-HMI asiza ukuloga kwedatha okuqhubekayo ukuze kuhlaziywe umlando nokuthrendayo. Amandla okuqapha angaphandle kwendawo avumela abaphathi ukuthi baphathe imisebenzi bekude. Idatha yemvelo, ehlanganisa ikhwalithi yamanzi, amaphrofayili amanje, ukuphakama kwamagagasi, nezimo zezulu, ukusekela okuqhubekayo ukuthobela kanye nokuphepha kokusebenza.

Ithiphu: Ukuqapha kwesikhathi sangempela kanye nezihibe zempendulo kuqinisekisa ukukhishwa okungaguquki, ukuthuthukisa ukusebenza kahle kwamandla, nokusiza opharetha baphendule ngokushesha ezimweni ezishintshayo.

Izici Zokuphepha Nezinqubo Eziphuthumayo

Izinhlelo zesimanje ze-Dredger Winch zifaka izindlela zokuphepha ezithuthukile zokuvikela abaqhubi nemishini. Ukuvikela ukulayisha ngokweqile okuzenzakalelayo, izitobhi eziphuthumayo, namasistimu okulwa nokugwazwa kunciphisa ukuchayeka ezimeni eziyingozi. Izici ze-automation ezifana ne-automated spooling kanye nokulawula ukuqina kokuqina kunciphisa ukungenelela okwenziwa ngesandla kanye namaphutha omuntu.

Amawintshi e-hydraulic asebenzisa ama-valve okulawula alinganayo, impendulo ye-loop evaliwe, nezilawuli ezinengqondo ezihlelekayo ukuthuthukisa ukulawula nokusebenza kahle. Ubuchwepheshe bezinzwa obuhlanganiswe nokuxhumana kwe-IoT bunika amandla ukugcinwa okubikezelwayo, ukunciphisa isikhathi sokuphumula nokuthuthukisa ukuphepha. Ama-opharetha angasebenzisa amaphrothokholi angaphumeleli kanye nokubhala ngaphezulu ngesandla ukuze kugcinwe ukuqhubeka esimeni sokulahleka kwesignali noma izehlakalo ezingalindelekile.

Ushintsho olusuka ezindleleni zemanuwali ukuya ezizenzakalelayo kuthuthukisa kakhulu ukuphepha nokusebenza kahle. Ama-opharetha ahlangabezana nokukhathala okuncane, alondoloze ukulawula okunembile, futhi agweme ukuchayeka ngokuqondile ezindaweni eziyingozi.

| Isici | Amawintshi ezandla (aphelelwe yisikhathi) | Amawintshi Amanzi (Okuncanyelwayo) |

|---|---|---|

| Indlela Yokulawula | Amalever angokomzimba nama-pedals onyawo adinga umzamo omkhulu | I-Hydraulic inikwe amandla ngezilawuli ze-elekthronikhi ezilinganayo |

| Umzamo Womsebenzi | Umzamo omkhulu womzimba oholela ekukhathaleni | Umzamo ophansi womzimba, unciphisa ukukhathala komsebenzisi |

| Ukunemba | Ukunyakaza okwenzeka njalo kodwa okuncane kuyakhathaza | Izimpaphe eziqondile zokulungiswa okuncane okugcina ukugeleza okufanayo |

| Ukuphepha | I-opharetha ichayeke emsindweni, ekushiseni, nasekuvuzekeni okungaba khona umshini wokubacindezela | I-opharetha ilawula iwintshi ukude ukusuka kukhebhu, inciphisa ukuchayeka ezingozini |

| Ukukhiqiza Ngempumelelo | Yehla njengamathayi o-opharetha | Kunyuswe ngenxa yokusebenza kalula kanye nokulawula okunembayo |

| Isondlo Nokwethenjelwa | Ukumakhenikha, kulula kodwa kufuna ngokomzimba | Idinga ukunakekelwa kwe-hydraulic kodwa ithuthukisa ukulawula nokusebenza nokuphepha |

| Izici Ezengeziwe | N/A | Izikali zokucindezela zokuqapha ukudonswa komugqa, ukuvikela ukugcwala ngokweqile, kanye nokusebenza kalula |

Ukulandelana Okujwayelekile Kokusebenza

Ukulandelana kokusebenza kwe-Dredger Winch kulandela inqubo ehlelekile yokuqinisekisa ukuphepha nokusebenza kahle:

- Qala injini futhi uyivumele ingenzi lutho kuze kufike izinga lokushisa lamanzi, izinga lokushisa likawoyela, nomfutho kawoyela kufinyelele emazingeni athile.

- Vula iswishi yokunikeza amandla kukhabethe lokulawula ngaphambi kokuvula iphampu yesihlabathi.

- Yehlisa iwintshi yesitebhisi, iladi, nepayipi lokumunca ukuze ucwilise i-cutterhead; qala iphampu yokugeza.

- Sebenzisa i-gearbox kanye nephampu yesihlabathishintsha iphaneli yokulawula; kancane kancane ukwandisa isivinini senjini kuya ku-rpm ecacisiwe.

- Uma amanzi esekhishiwe futhi ipayipi lokukhipha lisebenza kahle, vula i-cutterhead ukuze ukhiqize usebenzisa ukunyakaza kwe-lateral.

- Ngesikhathi sokusebenza, qapha izimo zenjini ngokubheka iphunga elingajwayelekile, imisindo, ukufundwa kwezinsimbi, ukuvuza kukawoyela we-hydraulic, ukuvuza kwamanzi okupholisa, nokudlidliza.

- Ukuze umise ukukhiqiza, phakamisa iwintshi yesitebhisi ukuze uphakamise i-cutterhead kusuka kungqimba lwesihlabathi.

- Qhubeka umpompa amanzi ukuze ukhiphe inzika epayipini elikhiphayo.

- Yehlisa isivinini senjini ukuze umise iphampu yesihlabathi.

- Phakamisa ileli ye-dredger ngaphezu kwezinga lamanzi futhi uyivikele ngezinyathelo zokuphepha.

- Ngaphambi kokuhamba, hlola futhi uvale ama-valve olwandle namanye, nqamula amandla, futhi uvale amafasitela nezicabha.

Ama-opharetha asebenzisana namasistimu azenzakalelayo asebenzisa ukuxhumana okuhlanganisiwe okuhlinzeka ngedatha yesikhathi sangempela, izexwayiso, namalogi. Izilawuli kude ezingenantambo zinika amandla ukuma okunembile kanye nokunyakaza kwamabheji okushelelayo. I-Adaptive logic kanye nempendulo yenzwa igcina ngokuzenzakalelayo amapharamitha e-winch ne-dredging. Ama-HMI e-ergonomic ahlinzeka ngendawo yokulawula enembile, kuyilapho amaphrothokholi angaphumeleli kanye nokubhala phansi okwenziwa ngesandla kuqinisekisa ukuphepha nokusebenza okuqhubekayo.

Amasu okuzenzakalela abhekana nezinselele zokusebenza ngokusebenzisa isilawuli sezimoto eziningi ezivumelanisiwe, izilawuli ze-PI ezingacacile, kanye nama-algorithms wokulinganisa ashukumisayo. Lezi zindlela zithuthukisa ukuqina, zigcine ukunyakaza okuzinzile phakathi nezigaba eziyinkimbinkimbi, futhi ziqinisekise ukuphepha ngokwenqatshwa okuphumelelayo kokuphazamiseka nokulawulwa kokulayishwa ngokweqile.

Qaphela: Abaqhubi kufanele bahlale beqaphile phakathi nesigaba ngasinye sokulandelana komsebenzi, besebenzisa kokubili izilawuli ezenziwa ngesandla nezizenzekelayo ukuze kugcinwe ukuphepha nokukhiqiza.

Ama-opharetha afinyelela ukusebenza kahle okukhulu nokuphepha ngezinhlelo zokulawula ze-Dredger Winch ezihlanganisa okuzenzakalelayo, ukuqapha kwesikhathi sangempela, nezindawo ezisebenziseka kalula.

- Ukulawula isivinini sokushwiba okuzenzakalelayo, ukulandelela i-GPS, nezilawuli zokucabanga ezihlelekayo kuthuthukisa ukunemba nokuphepha.

- Ukwenza idijithali kanye nokuxilongwa okukude kunciphisa iphutha lomuntu, kukhuphule ukukhiqiza, futhi kunciphise ubungozi bokusebenza.

FAQ

I-PLC ikuthuthukisa kanjani ukuphepha kwe-dredger winch?

I-PLC iqapha amapharamitha wesistimu, iphoqelela ukukhiya okuphephile, futhi icuphe ukuma kwezimo eziphuthumayo. Abasebenzisi bathembele kuma-PLC ukuze bavimbele ukugcwala ngokweqile nokuqinisekisa ukuthi kuphephile, kuthembekileukusebenza kwewintshi.

Ingabe opharetha bangakwazi ukulawula iwintshi bekude?

Yebo. Ama-opharetha asebenzisa izilawuli kude ezingenantambo noma amaphaneli asekelwe ogwini ukuzeisilawuli kude. Lesi sici sikhulisa ukuphepha kanye nokuguquguquka ngesikhathi sokusebenza kokudonsa.

Yikuphi ukunakekelwa okudingwa wuhlelo lokulawula iwintshi le-dredger?

Ama-opharetha enza ukuhlola okuvamile, ukuthambisa, nokuhlola izinzwa. Bashintsha izingxenye ezigugile njengoba kudingeka. Ukunakekelwa okujwayelekile kuqinisekisa ukusebenza okuthembekile futhi kwandisa ubude besikhathi semishini.

Isikhathi sokuthumela: Aug-31-2025