Hydraulic Slewing enables heavy machinery to rotate smoothly and precisely by converting pressurized fluid into mechanical movement. This process relies on hydraulic energy, which offers high efficiency—hydraulic pumps in these systems typically achieve around 75% efficiency. Operators can rely on this technology for consistent, controlled rotation in demanding applications.

Key Takeaways

- Hydraulic slewing uses pressurized fluid to create smooth, precise rotation in heavy machinery, relying on key parts like hydraulic motors, slewing bearings, pumps, and control valves.

- This system converts hydraulic energy into mechanical movement efficiently, offering strong torque and fine control, which helps machines handle heavy loads safely and accurately.

- Hydraulic slewing improves reliability, reduces energy use, and lowers maintenance needs, making it ideal for cranes, excavators, wind turbines, and marine equipment.

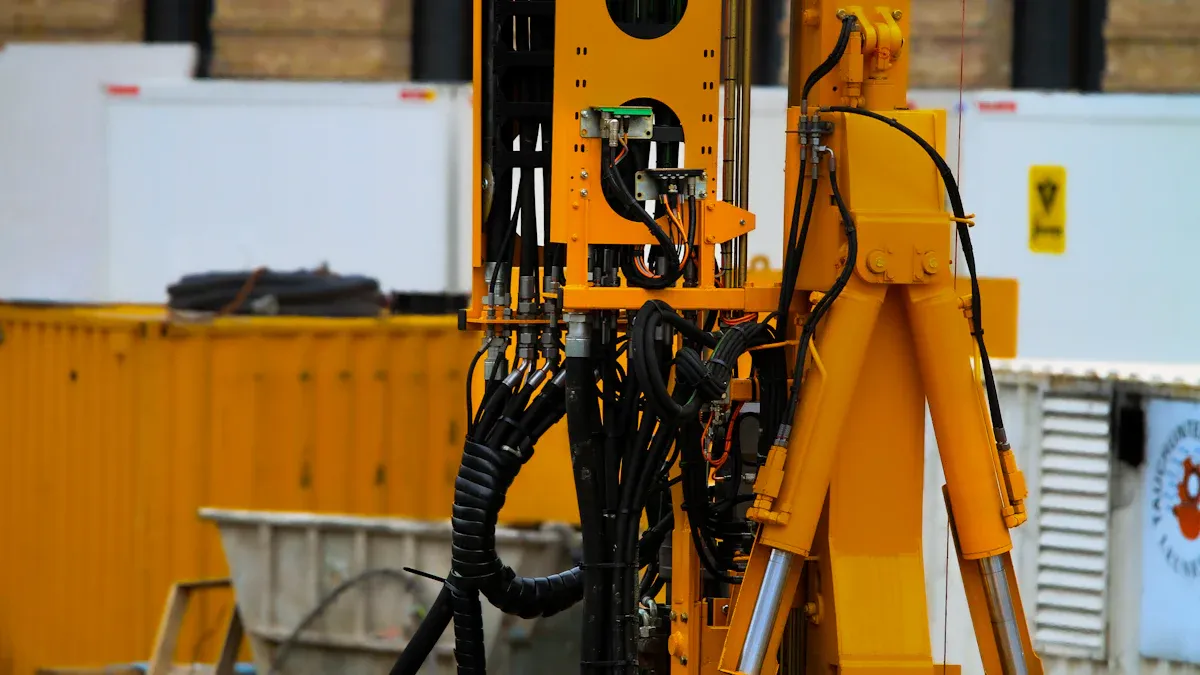

Hydraulic Slewing System Components

Hydraulic Motor

The hydraulic motor forms the core of the Hydraulic Slewing system. It converts hydraulic energy into mechanical rotation. This motor controls the speed and torque needed for smooth movement. Studies show that the performance of the hydraulic motor depends on how well it manages direction, pressure, and flow. Engineers use advanced control strategies to optimize speed and torque. Research also highlights the importance of energy efficiency and system stability in slewing applications. By understanding these factors, operators can achieve precise and reliable rotation.

Slewing Bearing

The slewing bearing supports the rotating structure and handles heavy loads. It allows the machinery to turn smoothly while carrying axial, radial, and overturning forces. Statistical studies use models like the Weibull distribution and Hertzian contact theory to predict the lifespan and load capacity of slewing bearings. These studies show that the fixed ring of a slewing bearing wears faster than the rotating ring. Engineers use advanced testing methods to estimate bearing life and ensure safety in heavy machinery such as cranes and wind turbines.

Hydraulic Pump and Reservoir

The hydraulic pump supplies pressurized fluid to the system, while the reservoir stores the hydraulic oil. High-quality pumps in Hydraulic Slewing systems often reach efficiency levels above 90%. Modern reservoir designs reduce size and weight, making the system more efficient. Operators must check fluid levels regularly and use clean, manufacturer-approved fluids. Maintenance tasks like replacing filters and oil help prevent contamination and extend system life. The table below compares traditional and modern reservoir designs:

| Aspect | Traditional Reservoir | Modern Reservoir |

|---|---|---|

| Size | 3–5x pump flow | 1:1 with pump flow |

| Weight | Heavy | Up to 80% lighter |

| Oil Volume | Large | Reduced by 80% |

Control Valves and Hoses

Control valves and hoses direct the flow of hydraulic fluid throughout the system. Reliable valves maintain stable pressure and ensure safe operation. Research on valve dynamics shows that well-designed valves handle pressure changes without losing stability. Quality seals prevent leaks and keep contaminants out. Properly routed hoses and secure connections help maintain system integrity. Engineers select durable materials for hoses and seals to withstand extreme conditions and reduce wear.

Hydraulic Slewing Working Principle

Step-by-Step Operation

Hydraulic Slewing systems follow a precise sequence to achieve smooth and controlled rotation. The process begins when the operator activates the control lever. This action sends pressurized hydraulic fluid from the pump through control valves and hoses to the hydraulic motor. The motor receives this energy and starts to rotate, turning the slewing bearing and the attached machinery.

Engineers often adjust the power control valve to a neutral position before measuring inlet and outlet pressures. They then calculate input and output power, as well as system efficiency. By incrementally closing the drain port in small steps, they observe how the valve position affects power transmission. This method demonstrates the valve’s role as a clutch, allowing for fine-tuned control during slewing operations. In some advanced systems, the sequence includes analyzing component importance and optimizing maintenance to ensure reliability. Each step, from power input to load handling, contributes to the stable and efficient operation of Hydraulic Slewing mechanisms.

Power Transmission and Conversion

Hydraulic Slewing systems excel at converting hydraulic energy into mechanical rotation. The hydraulic pump delivers pressurized oil to the motor, which then transforms this energy into torque. The slewing bearing distributes this torque, allowing the machinery to rotate under heavy loads. The efficiency of this process depends on several factors, such as accumulator pressure and volume.

Tip: Increasing the accumulator’s initial pressure or volume can lower the peak power demand and reduce energy consumption during slewing.

The table below highlights how different parameters affect power and energy use in slewing applications:

| Parameter | Condition/Value | Effect on Slewing Motor Power and Energy Consumption |

|---|---|---|

| Accumulator Initial Pressure | Higher | Peak power decreases, energy use decreases |

| Accumulator Volume | 350–500 L | Larger volume lowers peak power and energy use |

| Hybrid vs Pure Electric System | Hybrid system | Peak power and energy use reduced by up to 29.6% |

| Hoisting Motor Peak Power | Pure electric: 600 kW | Hybrid: 380 kW (36.7% reduction) |

| Energy Consumption per Cycle | Pure electric: 4332 kJ | Hybrid: 3048 kJ (29.6% energy saving) |

Hybrid systems further improve efficiency by recovering energy during deceleration and reusing it during acceleration. This approach reduces both peak power requirements and overall energy consumption, making Hydraulic Slewing systems highly efficient for heavy-duty applications.

Control and Precision

Modern Hydraulic Slewing systems deliver exceptional control and precision. Secondary control solutions enable high accuracy and dynamic response, even in large-scale equipment like mobile cranes with slewing rings up to 50 meters in diameter. These systems maintain reliability and energy efficiency while meeting strict precision standards.

Advanced control techniques, such as nonlinear PID and neural network model predictive control, have significantly improved positioning accuracy. For example, some systems have reduced positioning errors from 62 mm to within 10 mm. These improvements also lead to energy savings, with reductions of up to 15.35% under no-load conditions.

High-precision slewing bearings play a crucial role in maintaining accuracy. Manufacturers use specialized raceway designs and high-strength materials to ensure consistent performance, even under heavy loads and extreme conditions. This combination of advanced controls and robust components allows Hydraulic Slewing systems to achieve smooth, accurate movement essential for demanding industrial tasks.

Advantages and Applications of Hydraulic Slewing

Key Benefits

Hydraulic Slewing offers several important benefits for heavy machinery. The system provides smooth and controlled rotation, which helps operators position equipment with high accuracy. Hydraulic Slewing systems handle large loads with ease. They deliver strong torque, making them ideal for demanding tasks. The technology also improves safety by allowing precise movement, even in tight spaces.

Many engineers value the reliability of Hydraulic Slewing. The system works well in harsh environments, such as construction sites or offshore platforms. Maintenance needs remain low because the components resist wear and damage. Operators can trust the system to perform consistently over long periods.

Note: Hydraulic Slewing systems often reduce energy use and operating costs. This efficiency helps companies save money and protect the environment.

Common Uses in Machinery

Hydraulic Slewing appears in many types of heavy equipment. The following list shows some common applications:

- Cranes use Hydraulic Slewing to rotate their booms and lift heavy loads.

- Excavators rely on the system to turn their upper structures for digging and dumping.

- Wind turbines use slewing drives to adjust the direction of the blades.

- Marine vessels employ Hydraulic Slewing for deck machinery and winches.

- Construction vehicles, such as concrete pumps and aerial platforms, use the system for precise positioning.

The table below highlights typical machines and their slewing functions:

| Machine Type | Slewing Function |

|---|---|

| Crane | Boom rotation |

| Excavator | Upper structure turning |

| Wind Turbine | Blade direction control |

| Marine Vessel | Deck machinery movement |

| Concrete Pump Truck | Boom positioning |

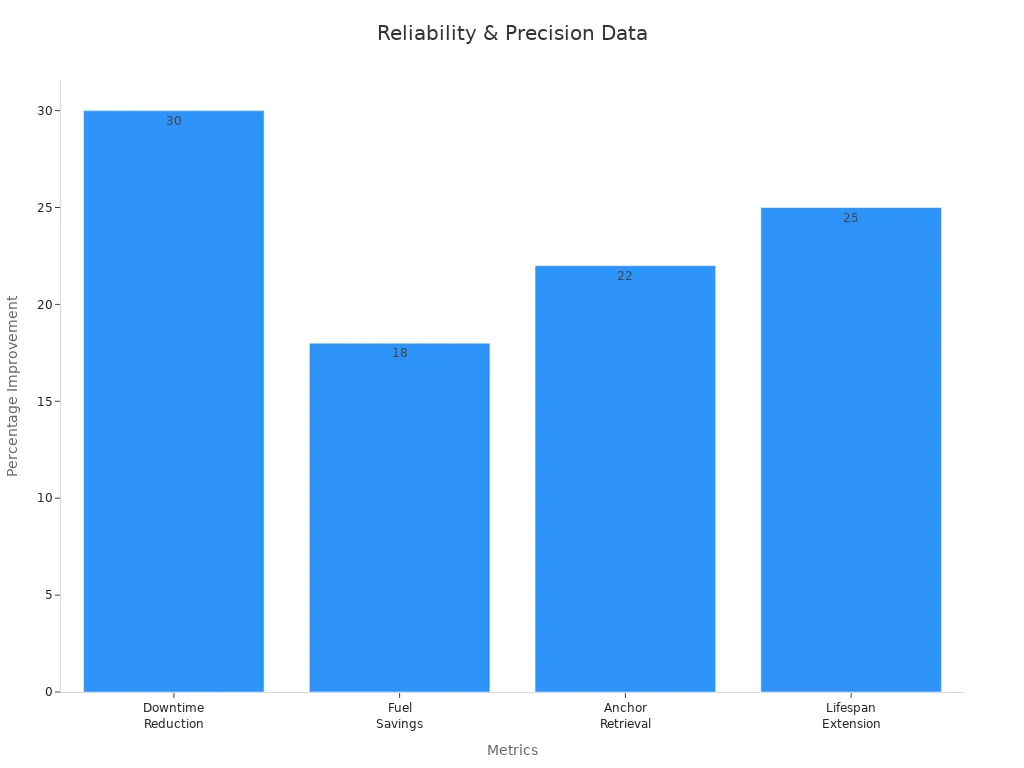

Hydraulic slewing systems set new standards for reliability and precision in heavy equipment. Operators report a 30% reduction in downtime and 18% fuel savings over three years.

| Metric / Test Description | Result / Improvement |

|---|---|

| Downtime reduction in hydraulic systems | 30% decrease |

| Fuel savings in maritime logistics | 18% savings over 3 years |

| Anchor retrieval speed during storms | 22% faster |

| Motor failure incidents in maritime vessels | Zero failures over 3 years across 12 vessels |

| Continuous operation of hydraulic gear pumps | 8,000 hours without performance loss |

| Hydraulic winch efficiency | Up to 95% |

| Lifespan extension due to reinforced materials | 25% longer lifespan |

| Operating temperature range | -40°F to 300°F |

Advanced engineering, including finite element analysis, ensures accurate stress prediction and safe operation. Statistical models help optimize maintenance, supporting precise control in industrial environments.

FAQ

What is hydraulic slewing used for?

Hydraulic slewing rotates heavy equipment, such as cranes and excavators. Operators use it for precise positioning and smooth movement in construction, marine, and energy industries.

How does a hydraulic slewing bearing work?

The slewing bearing supports the rotating structure. It handles heavy loads and allows smooth, controlled rotation by distributing forces evenly across its rings and rolling elements.

How often should operators maintain hydraulic slewing systems?

Operators should inspect fluid levels and check for leaks weekly. Regular maintenance, such as filter changes and oil replacement, helps ensure reliable performance and extends system life.

Post time: Jul-06-2025