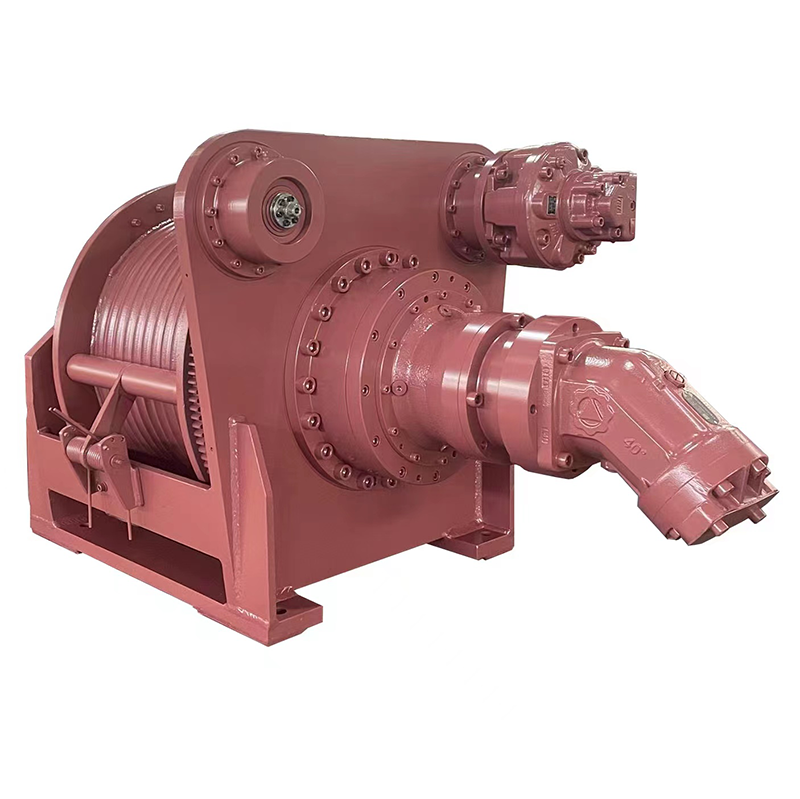

Hydraulic Winch systems dominate heavy-duty markets with unmatched power and reliability. Industries such as mining, construction, and oil & gas rely on these winches for handling extremely heavy loads.

| Aspect | Details |

|---|---|

| Market Value | USD 6.6 Billion |

| Forecast 2034 | USD 13.8 Billion |

Key Takeaways

- Hydraulic winches provide powerful, reliable lifting with high load capacity and continuous operation, making them ideal for tough heavy-duty jobs.

- These winches offer precise control and advanced safety features, helping operators handle heavy loads safely and efficiently.

- Durable design and resistance to harsh environments make hydraulic winches a cost-effective choice for industries like mining, construction, and marine.

Hydraulic Winch Types Compared

Electric vs. Hydraulic Winch

Electric and hydraulic winches serve different needs in heavy-duty operations. Hydraulic winches deliver higher pull capacity and maintain consistent power, even in harsh outdoor environments. They show greater durability and strength, making them a top choice for industries that demand reliable performance under stress. However, hydraulic winches require more complex installation and regular maintenance due to their fluid systems. Operators must understand both fluid dynamics and electronic controls to use them safely.

Electric winches, in contrast, offer easier installation and lower maintenance. They operate more quietly and efficiently, which suits indoor or controlled environments. Electric winches cost less and work well for lighter loads. However, they may not match the strength or continuous power of a hydraulic winch in demanding conditions. Studies highlight that hydraulic winches excel in situations where durability and consistent torque are critical, while electric winches fit applications that prioritize simplicity and cost-effectiveness.

Mechanical and Pneumatic Winch Overview

Mechanical winches use gears and manual effort or motors to lift and pull loads. They often appear in marine, oilfield, and construction settings. These winches feature corrosion-resistant materials and robust gear mechanisms. Mechanical systems usually have lower maintenance costs but require frequent inspections and manual operation. Pneumatic winches, powered by compressed air, provide a safe option in hazardous environments. They are common in projects where electrical sparks pose risks.

Note: Operator training and adherence to safety manuals remain essential for both mechanical and pneumatic winches. Technical consultancy and load testing help ensure safe and efficient lifting operations.

Mechanical winches offer efficiency and reliability, while pneumatic winches add safety in explosive or confined spaces. Both types play vital roles in industrial lifting and pulling tasks.

How a Hydraulic Winch Works

Hydraulic System Operation

A hydraulic winch uses pressurized fluid to generate powerful and controlled movement. The system relies on Pascal’s law, which distributes pressure evenly throughout the hydraulic fluid. This principle allows the winch to lift and pull heavy loads with precision. Operators benefit from consistent pulling power, even during long periods of use. Hydraulic winches do not overheat easily, making them ideal for demanding environments. Modern systems often include features such as increased line speed and remote operation. These advancements help reduce operator fatigue and improve safety.

Technical studies highlight the advantages of hydraulic systems in heavy-duty operations. For example, research on hydraulic-powered PTO winches for trucks shows that these systems deliver higher pulling force and smoother control than electric winches. Advanced designs use digital hydraulic pumps and motors, which improve efficiency and responsiveness. These systems use fast-switching valves to control pistons, reducing energy loss and enhancing performance under heavy loads.

Tip: Hydraulic winches provide precise handling of heavy objects, which improves safety and efficiency on job sites.

Key Components

A hydraulic winch consists of several essential parts. Each component plays a specific role in the system’s performance.

| Component | Function |

|---|---|

| Drum | Holds and winds the cable; made from high-strength steel for durability. |

| Hydraulic Motor | Converts fluid pressure into mechanical energy to turn the drum. |

| Hydraulic Pump | Supplies high-pressure fluid, often powered by the vehicle’s engine. |

| Control Valve | Regulates fluid flow, controlling speed and direction. |

| Brake System | Secures the load and controls movement when stopped. |

| Fairlead | Guides the cable onto the drum evenly, reducing wear. |

| Reservoir | Stores hydraulic fluid and helps manage system pressure. |

| Gear System | Increases torque and manages load efficiently. |

Manufacturers design each component to handle the stress of heavy-duty tasks. For example, industrial and marine hydraulic winches use corrosion-resistant materials and high-tensile cables to withstand harsh conditions.

Key Benefits of Hydraulic Winch in Heavy-Duty Operations

High Load Capacity and Torque

Hydraulic winches deliver exceptional load capacity and torque, making them essential for heavy-duty tasks. Independent tests and simulation studies confirm these capabilities. Engineers constructed a dedicated workbench to analyze a gerotor hydraulic motor, which is known for high torque at low speeds. They measured flow, pressure, rotation, and torque under different loads. The hydraulic winch system was modeled and validated on a test rig, with pressure drops across the motor carefully monitored. Hardware-in-the-loop tests and sea trials further demonstrated the system’s performance in real-world conditions, including dynamic wire-load interactions caused by currents and vessel movement. These tests showed that hydraulic winches can handle variable loading and require advanced control systems to manage torque and speed. Simulations of digital hydraulic winch drives with a safe working load of 20,000 kg outperformed conventional systems, confirming their efficiency and control. These results prove that hydraulic winches can manage heavy payloads and deliver high torque, even in demanding subsea operations.

Continuous and Reliable Performance

Hydraulic winches operate continuously without overheating or losing power. This reliability is critical in industries such as construction, mining, and marine operations. Operators can depend on these winches for long shifts and challenging environments. The hydraulic system uses fluid pressure, which provides consistent force and smooth operation. Unlike electric winches, hydraulic models do not suffer from electrical failures or rapid wear. This advantage ensures that projects stay on schedule and equipment downtime remains minimal.

Tip: Continuous operation reduces the risk of delays and increases productivity on job sites.

Durability and Longevity

Manufacturers design hydraulic winches for maximum durability. They use corrosion-resistant materials and robust engineering to withstand harsh environments. These winches resist damage from saltwater, dust, and extreme temperatures. Technological advancements, such as improved materials and safety features, further extend the lifespan of each unit. Hydraulic winches require less maintenance because they have fewer moving parts and avoid overheating. This durability makes them a cost-effective investment for companies that need reliable equipment over many years.

- Hydraulic winches demonstrate resilience in harsh environments and economic fluctuations.

- Innovations in materials and safety features improve durability and reduce workplace accidents.

- Leading manufacturers invest in smart technologies and high-capacity models for demanding applications.

Safety and Operational Control

Safety remains a top priority in heavy-duty operations. Hydraulic winches offer advanced control systems that enhance operator safety. The braking system is hydraulically controlled, ensuring reliable and automatic engagement and release. Operators benefit from variable speed control, which allows precise handling of heavy loads. Automated control systems and remote diagnostics further improve safety and ease of use. These features help prevent accidents and protect both workers and equipment.

- Hydraulic winches offer smooth and precise operation with variable speed control.

- The braking system ensures reliable and automatic brake engagement and release.

- Advanced features include automated control systems and remote diagnostics.

Real-World Applications

Hydraulic winches play a vital role in many industries. They support infrastructure development, oil and gas exploration, and renewable energy projects. Specialized types, such as marine, mooring, towing, anchor, and construction winches, address specific heavy-duty needs. These winches integrate seamlessly with existing hydraulic systems on vehicles and machinery. Their unmatched power and durability make them the preferred choice for critical tasks in marine, construction, and industrial sectors.

- Hydraulic winches are favored in heavy-duty applications due to superior performance and efficiency.

- The market is driven by sectors that require reliable and robust lifting solutions.

- Industry trends toward automation and sustainability highlight the ongoing importance of hydraulic winches.

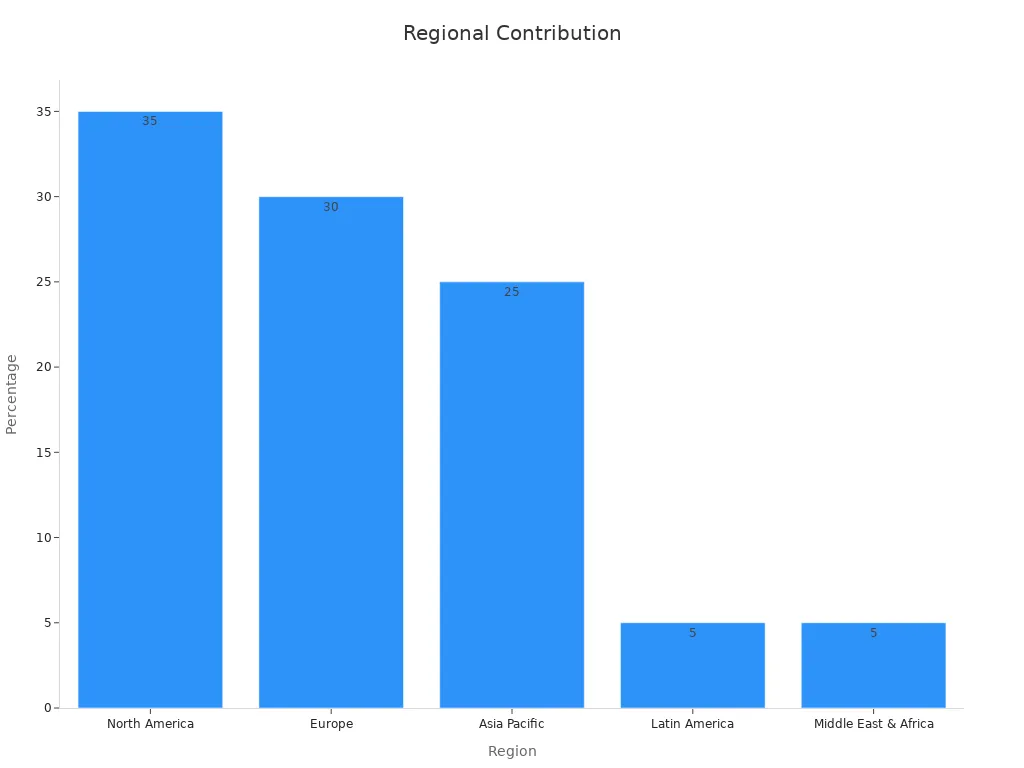

Market data shows strong growth in the automotive winches system market, with industry leaders choosing hydraulic winches for their reliability in tough environments.

- They deliver safe, precise control in high-pressure and deep well tasks.

- Safety features and remote monitoring help protect workers and equipment.

- Their durability and load capacity support critical operations in marine and mining.

FAQ

What industries use hydraulic winches most often?

Mining, construction, marine, and oil & gas industries rely on hydraulic winches. These sectors need strong, reliable equipment for lifting and pulling heavy loads.

How does a hydraulic winch improve job site safety?

Hydraulic winches offer precise control and automatic braking. Operators can manage loads safely, reducing the risk of accidents or equipment failure.

Can hydraulic winches operate in extreme weather?

- Yes, hydraulic winches work well in harsh environments.

- They resist damage from water, dust, and temperature changes.

- Operators trust them for outdoor and offshore tasks.

Post time: Jun-15-2025