Hydraulic friction winches are revolutionizing heavy-load handling in industries like construction and mining. These machines deliver unmatched strength and reliability, making them indispensable for demanding tasks. The global hydraulic winch drives market is projected to grow at a 5.5% CAGR from 2025 to 2030. This rise underscores their critical role in applications requiring precision and power, such as crane hydraulic dual winch systems.

Key Takeaways

- Hydraulic friction winches are important for lifting heavy loads in jobs like building and mining. They are strong and dependable.

- Buying good hydraulic winches can save money over time. They need less fixing and work better for longer.

- New hydraulic winches use smart technology, like speed controls. This helps them work better and use less energy in tough tasks.

Key Features of Hydraulic Friction Winches

Load Capacity and Strength

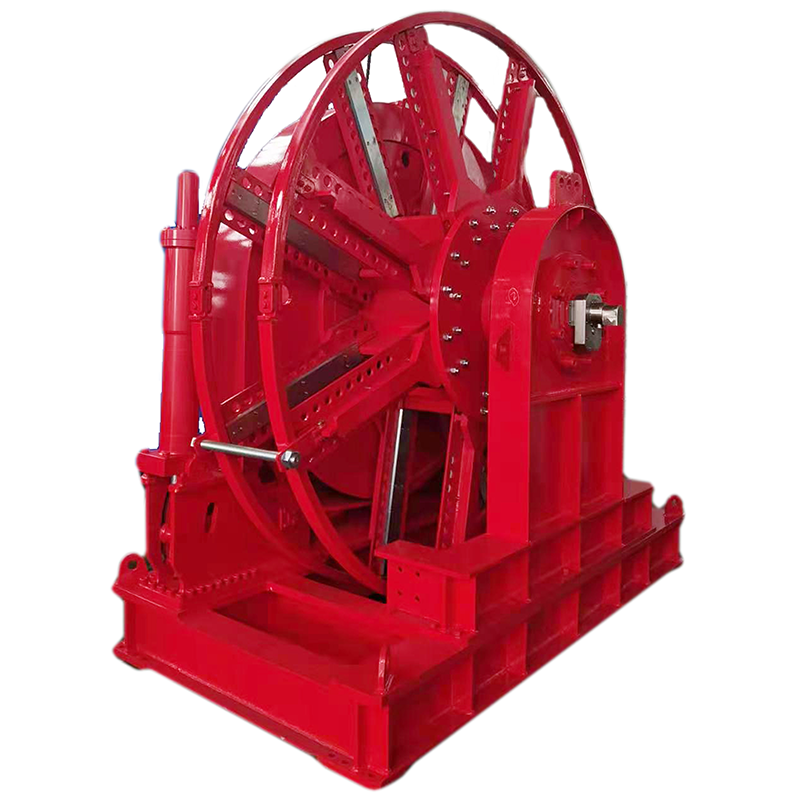

Hydraulic friction winches are engineered to handle immense loads with precision. Their robust construction allows them to lift and pull heavy materials in industries like construction, mining, and marine operations. These winches often feature advanced hydraulic systems that distribute force evenly, reducing strain on the equipment. Models designed for 2025 boast load capacities ranging from 10 to 25 tons, making them suitable for demanding tasks. Operators rely on these machines to maintain consistent performance under extreme conditions, ensuring safety and efficiency.

Efficiency and Operational Performance

Efficiency remains a cornerstone of every hydraulic friction winch. Modern designs incorporate energy-saving mechanisms, such as variable-speed controls and automatic braking systems. These features optimize power usage while minimizing wear and tear. Additionally, the hydraulic systems provide smooth and precise operation, allowing users to handle delicate or heavy materials with ease. The ability to maintain consistent torque and speed ensures that these winches perform reliably in both high-stress and precision-driven applications.

Durability and Material Quality

Durability defines the long-term value of a hydraulic friction winch. Manufacturers use high-grade materials like stainless steel and corrosion-resistant coatings to withstand harsh environments. These winches are built to endure exposure to moisture, salt, and extreme temperatures, making them ideal for marine and offshore operations. Reinforced components and rigorous testing ensure that each unit meets industry standards for reliability. This focus on quality extends the lifespan of the equipment, reducing maintenance costs over time.

Top Hydraulic Friction Winch Models for 2025

Mile Marker 70-52000C H Series

The Mile Marker 70-52000C H Series stands out as a reliable choice for heavy-duty applications. Designed with a focus on strength and precision, this hydraulic friction winch offers a load capacity of up to 20 tons. Its compact design ensures easy integration into various industrial setups, while its advanced hydraulic system delivers consistent torque. Operators benefit from its variable-speed control, which enhances efficiency during both high-speed and precision tasks. The winch's rugged construction, featuring corrosion-resistant materials, ensures durability in harsh environments. This model has gained popularity among professionals in construction and marine industries for its dependable performance and long service life.

Superwinch H8P

The Superwinch H8P combines power and versatility, making it a top contender for 2025. With a load capacity of 18 tons, this hydraulic friction winch is ideal for demanding tasks in industries like mining and offshore operations. Its innovative design includes a dual-speed system, allowing users to switch between rapid line retrieval and precise load handling. The winch's hydraulic motor operates quietly, reducing noise pollution in work environments. Additionally, its compact dimensions and lightweight build simplify transportation and installation. The Superwinch H8P's robust materials and advanced sealing technology protect it from moisture and debris, ensuring reliable operation even in extreme conditions.

JP 25 Tonne Industrial Hydraulic Winch

The JP 25 Tonne Industrial Hydraulic Winch represents the pinnacle of heavy-load handling. With a massive load capacity of 25 tons, this model caters to the most demanding industrial applications. Its hydraulic system provides smooth and controlled operation, enabling users to handle heavy materials with precision. The winch's high-speed mode achieves line speeds of up to 65 meters per minute, while its fine-tuning mode allows for meticulous adjustments. Manufacturers have incorporated corrosion-resistant coatings and reinforced components to enhance durability. This model's ability to transition seamlessly between hydraulic and electric systems has improved efficiency and reduced noise, making it a preferred choice for modern vessels and offshore platforms.

Note: The latest advancements in hydraulic friction winch technology, such as those seen in the JP 25 Tonne model, highlight the industry's commitment to improving efficiency and user experience. These innovations ensure that operators can rely on their equipment for both heavy-duty and precision-driven tasks.

Pricing and Value Analysis

Comparative Price Ranges

Hydraulic friction winches vary significantly in price, depending on their load capacity, features, and build quality. Entry-level models designed for lighter industrial tasks typically range from $5,000 to $10,000. These units offer basic functionality and are suitable for operations with moderate load requirements. Mid-tier winches, such as the Superwinch H8P, fall within the $10,000 to $20,000 range. These models provide enhanced features like dual-speed systems and corrosion-resistant materials, making them ideal for more demanding applications. High-capacity winches, including the JP 25 Tonne Industrial Hydraulic Winch, can exceed $30,000, reflecting their advanced hydraulic systems and exceptional durability.

Tip: Buyers should evaluate their operational needs carefully. Investing in a higher-priced model often ensures better performance and longevity, reducing the need for frequent replacements.

Long-Term Cost-Effectiveness

While the initial cost of a hydraulic friction winch may seem high, its long-term value often outweighs the upfront expense. Premium models, built with durable materials and advanced technology, require less frequent maintenance. This reduces downtime and repair costs over time. For example, corrosion-resistant coatings and reinforced components extend the lifespan of these machines, especially in harsh environments like offshore platforms.

Energy efficiency also plays a critical role in cost-effectiveness. Modern winches with variable-speed controls and energy-saving mechanisms consume less power, lowering operational expenses. Additionally, their reliability minimizes the risk of project delays, which can lead to significant financial losses.

Note: Investing in a high-quality winch not only enhances operational efficiency but also ensures a better return on investment over its lifecycle.

Applications of Hydraulic Friction Winches

Industrial and Commercial Use

Hydraulic friction winches play a vital role in industrial and commercial operations. Their ability to handle heavy loads with precision makes them indispensable for tasks such as material handling, assembly line operations, and warehouse logistics. Industries rely on these winches to move bulky items efficiently, reducing manual labor and increasing productivity. Their advanced hydraulic systems ensure smooth operation, even under high-stress conditions.

Tip: Businesses can enhance operational efficiency by integrating hydraulic winches into automated systems, streamlining workflows and minimizing downtime.

Marine and Offshore Operations

Marine and offshore industries demand equipment that can withstand harsh environments. Hydraulic friction winches excel in these conditions due to their corrosion-resistant materials and robust construction. They are commonly used for lifting and installing heavy payloads, such as anchors, pipelines, and "christmas trees" in offshore platforms. These operations require precise control, which is validated through Hardware In the Loop (HIL) tests and simulations. The winches are designed to handle environmental forces and wire-load dynamics, ensuring reliable performance in challenging scenarios.

Note: The durability and precision of hydraulic winches make them a preferred choice for offshore applications, where safety and efficiency are paramount.

Construction and Heavy Equipment Tasks

Construction sites benefit significantly from hydraulic friction winches. These machines are essential for lifting and positioning heavy equipment, structural components, and building materials. Their ability to operate under extreme loads ensures that projects progress smoothly without delays. Performance tests validate their effectiveness in handling complex tasks, such as installing pipelines and anchors. Advanced modeling techniques simulate environmental forces, ensuring the winches meet stringent performance criteria.

- Key Use Cases:

- Lifting steel beams for skyscraper construction.

- Installing heavy machinery in industrial facilities.

- Handling oversized loads in infrastructure projects.

Hydraulic friction winches provide construction teams with the reliability and strength needed to complete demanding tasks efficiently. Their versatility makes them a cornerstone of modern construction operations.

Each hydraulic friction winch model excels in specific areas. The JP 25 Tonne model offers unmatched load capacity, while the Superwinch H8P provides versatility. For marine tasks, the Mile Marker 70-52000C H Series stands out. Buyers should assess their operational needs and budget to select the most suitable option for long-term efficiency.

FAQ

What maintenance is required for hydraulic friction winches?

Regular inspections, lubrication of moving parts, and checking hydraulic fluid levels ensure optimal performance. Replace worn components promptly to avoid operational failures.

Tip: Schedule routine maintenance to extend the winch's lifespan and reduce downtime.

Can hydraulic friction winches operate in extreme weather conditions?

Yes, most models feature corrosion-resistant materials and robust seals, enabling reliable performance in harsh environments, including extreme temperatures and high humidity.

How do hydraulic friction winches compare to electric winches?

Hydraulic winches offer superior load capacity and durability. They excel in heavy-duty applications, while electric winches are better suited for lighter tasks requiring portability.

Note: Choose based on operational needs and environmental factors.

Post time: Jun-12-2025