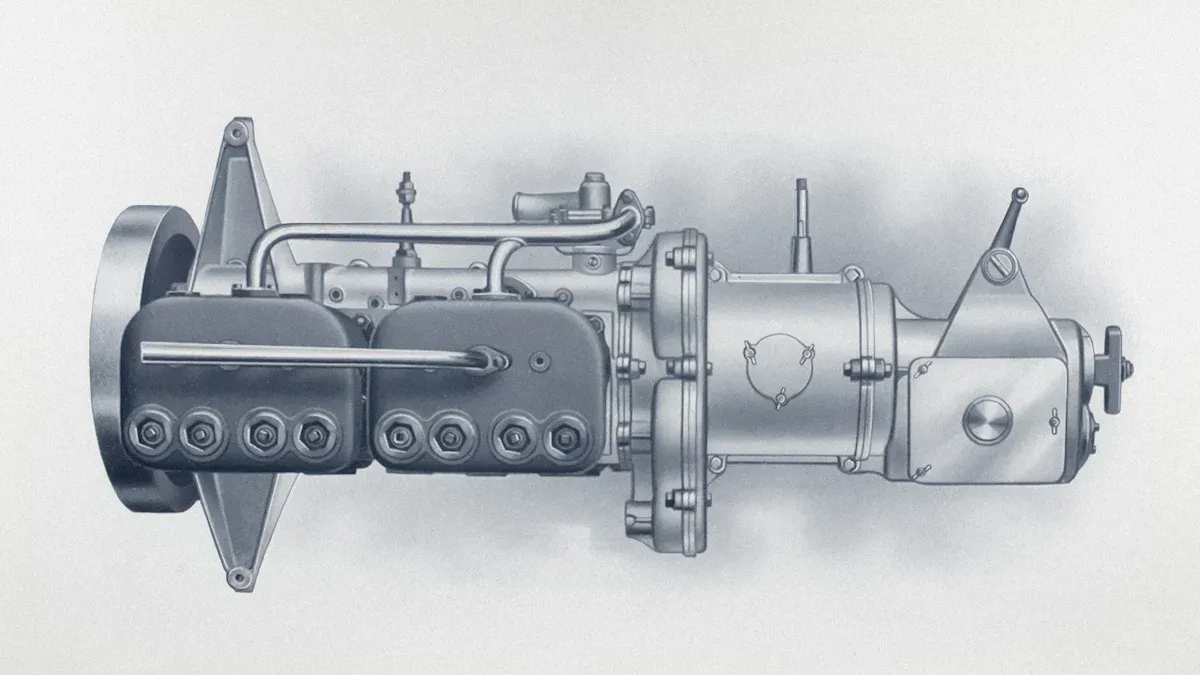

Hydraulic motors, such as those produced in a hydraulic motor factory, combine compact design with immense power, making them vital in heavy-duty applications. These ini hydraulic motors deliver exceptional torque and power density by converting hydraulic energy into mechanical force. Industries rely on hydraulic motors for tasks such as powering excavators, tractors, and cranes. Their efficiency in low-speed, high-torque scenarios sets them apart from other systems.

Key Takeaways

- Hydraulic motors change liquid energy into mechanical force. They give strong turning power and are great for heavy work.

- Important things that affect motor power are flow speed, pressure, and size. Keeping these in good shape helps them work better and last longer.

- Hydraulic motors work well in tough places. They are dependable and efficient when electric systems stop working. This makes them perfect for building, ships, and airplanes.

Factors That Influence Hydraulic Motor Power

Flow Rate and Pressure

The power of a hydraulic motor depends significantly on the flow rate and pressure of the hydraulic fluid. Flow rate determines the speed at which the motor operates, while pressure dictates the torque it can generate. Together, these factors define the motor's overall power output.

Hydraulic systems rely on pumps to deliver fluid at specific flow rates and pressures. A higher flow rate allows the motor to rotate faster, whereas increased pressure enables it to handle heavier loads. For example, a hydraulic motor operating at 3,000 PSI (pounds per square inch) and a flow rate of 20 GPM (gallons per minute) can produce substantial power suitable for demanding applications like construction equipment or industrial machinery.

Tip: Maintaining optimal pressure and flow rate is crucial for maximizing the performance and longevity of a hydraulic motor.

Displacement and Motor Design

Displacement refers to the volume of fluid a hydraulic motor displaces per revolution. Motors with larger displacement generate higher torque but operate at lower speeds, making them ideal for applications requiring significant force. Conversely, motors with smaller displacement offer higher speeds but lower torque.

Motor design also plays a critical role in performance. Common designs include gear, vane, and piston motors, each suited for specific tasks. For instance:

- Gear motors are compact and cost-effective, often used in mobile equipment.

- Vane motors provide smooth operation and are suitable for industrial applications.

- Piston motors deliver high efficiency and power, making them ideal for heavy-duty tasks.

Selecting the right motor design and displacement ensures the hydraulic motor meets the application's specific requirements.

Efficiency and Energy Losses

Efficiency is a key factor influencing the power of a hydraulic motor. It determines how effectively the motor converts hydraulic energy into mechanical energy. Two primary types of efficiency are considered: volumetric efficiency and overall efficiency.

- Volumetric efficiency measures the ratio of actual output to theoretical output. For example, a hydraulic pump with a theoretical output of 100 GPM and an actual output of 94 GPM achieves a volumetric efficiency of 94%.

- Overall efficiency accounts for both volumetric and mechanical losses. A system with a volumetric efficiency of 92% may have an overall efficiency of 85%, reflecting additional energy losses due to friction and heat.

Energy losses can occur due to factors like fluid leakage, friction between components, and heat generation. Minimizing these losses enhances the motor's performance and reduces operational costs.

Note: Regular maintenance and proper system design can significantly improve the efficiency of hydraulic motors, ensuring reliable and cost-effective operation.

Torque Output and Its Role in Hydraulic Motor Power

Breakaway Torque vs. Running Torque

Torque plays a pivotal role in the performance of a hydraulic motor. Two key types of torque—breakaway torque and running torque—define its operational capabilities:

- Breakaway torque refers to the maximum torque required to initiate movement in a load. It must overcome both inertia and static friction.

- Running torque is the lower torque needed to maintain motion once the load is in motion. Resistance decreases significantly during this phase.

Both types of torque are critical when specifying a hydraulic motor. Insufficient breakaway torque can prevent a motor from starting, while inadequate running torque may lead to stalling during operation. Proper torque specifications ensure efficient and reliable performance in demanding applications.

How Torque Relates to Power

Torque and power are closely linked in hydraulic motors. Power is calculated as the product of torque and rotational speed. High torque at low speeds is a hallmark of hydraulic motors, making them ideal for applications requiring significant force. For example, a hydraulic motor delivering 500 lb-ft of torque at 100 RPM generates substantial power for heavy-duty tasks. This relationship highlights the motor's ability to handle high loads without compromising efficiency.

Examples of High-Torque Applications

Hydraulic motors excel in industries requiring high torque. Some notable applications include:

- Construction Equipment: Excavators use hydraulic motors to power tracks, enabling precise control and powerful digging.

- Wind Turbines: Hydraulic motors adjust blade pitch, optimizing energy generation in varying wind conditions.

- Marine Propulsion: Ships rely on hydraulic motors for bow thrusters, ensuring precise maneuvering in tight spaces.

- Industrial Mixers: These motors provide variable speed and high torque, essential for mixing dense materials effectively.

These examples demonstrate the versatility and power of hydraulic motors in diverse, high-torque scenarios.

Comparing Hydraulic Motors to Other Systems

Power Density and Compactness

Hydraulic motors are renowned for their exceptional power density and compact design. These motors deliver high power output relative to their size and weight, making them ideal for applications where space and weight constraints are critical. For instance, Bosch Rexroth hydraulic motors achieve a power density of up to 1.5 kW/kg, showcasing their ability to provide significant power in a compact form. This feature makes them indispensable in industries such as aerospace and mobile machinery, where efficiency and space optimization are paramount.

The following table highlights the comparative advantages of hydraulic motors over electric systems in terms of power density and other features:

| Feature | Hydraulic Motors | Electric Systems |

|---|---|---|

| Power Density | High power output at a small size and weight | Generally lower power density |

| Starting Torque | High starting torque at low speeds | Lower starting torque |

| Flexibility and Adjustability | Precise control of speed and torque | Limited adjustability |

Hydraulic motors also maintain high efficiency, with ratings exceeding 90%, minimizing energy losses during operation. This combination of compactness and efficiency ensures their suitability for demanding environments.

Efficiency in Harsh Environments

Hydraulic motors excel in harsh environments where other systems may falter. Their robust construction allows them to withstand extreme temperatures, high pressures, and exposure to dust or moisture. Unlike electric systems, which may suffer from overheating or electrical failures, hydraulic motors continue to perform reliably under challenging conditions.

For example, in marine applications, hydraulic motors power bow thrusters, ensuring precise maneuvering even in corrosive saltwater environments. Similarly, in construction, these motors operate heavy machinery like excavators and cranes, enduring constant exposure to dirt and debris. Their ability to maintain performance in such conditions underscores their reliability and durability.

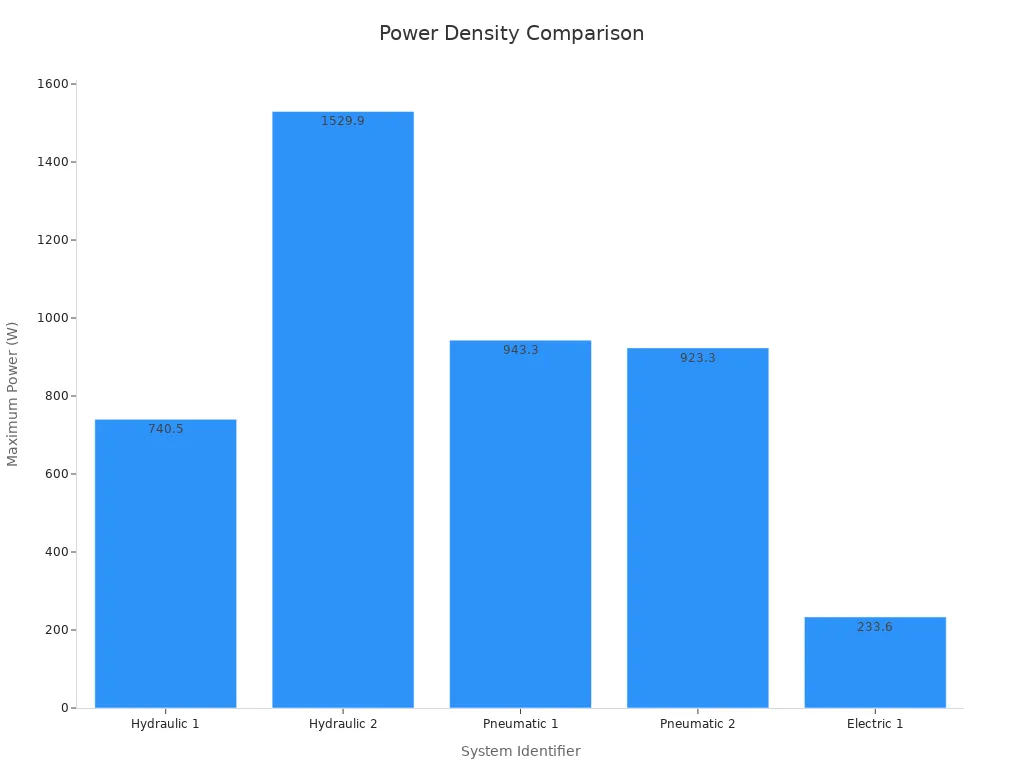

The chart below compares the maximum power values of hydraulic, pneumatic, and electric systems, further illustrating the advantages of hydraulic motors in demanding applications:

Cost and Maintenance Considerations

While hydraulic motors offer numerous advantages, their cost and maintenance requirements must be considered. These motors often involve higher initial costs and more complex maintenance compared to electric systems. For example, operations and maintenance (O&M) costs for hydraulic systems can range from $56 to $240 per year, depending on the application and system type.

However, their long lifespan and ability to handle heavy-duty tasks often offset these costs. Effluent sewer pumps, a type of hydraulic system, can last over 25 years with proper maintenance. In contrast, grinder pumps, which are more maintenance-intensive, require repairs every 8 to 10 years and replacement every 16 to 20 years.

To minimize costs, regular maintenance and proper system design are essential. By addressing potential issues like fluid leakage and component wear, operators can extend the lifespan of hydraulic motors and reduce long-term expenses.

Tip: Investing in high-quality components and adhering to a strict maintenance schedule can significantly lower the total cost of ownership for hydraulic motors.

Real-World Applications of Hydraulic Motors

Industrial Machinery and Equipment

Hydraulic motors play a vital role in industrial machinery, delivering reliable power for demanding tasks. These motors operate equipment such as conveyor belts, presses, and mixers, ensuring consistent performance under heavy loads. Their ability to provide high torque at low speeds makes them indispensable in manufacturing and processing industries.

The efficiency of hydraulic motors in industrial applications depends on the type of hydraulic fluid used. For example, fluids like HEES46 and HBMO46+FM reduce low-speed torque losses by half compared to conventional fluids. These fluids also enhance mechanical efficiency at lower speeds, ensuring optimal performance.

| Hydraulic Fluid | Low-Speed Torque Losses | Mechanical Efficiency |

|---|---|---|

| HEES46 | Half of conventional fluid | Higher at low speeds |

| HBMO46+FM | Half of conventional fluid | Higher at low speeds |

| Conventional | Standard torque losses | Lower at low speeds |

This data highlights the importance of selecting the right hydraulic fluid to maximize the efficiency of hydraulic motors in industrial machinery.

Mobile Applications in Construction and Agriculture

Hydraulic motors are essential in mobile equipment used in construction and agriculture. Excavators, loaders, and tractors rely on these motors to perform tasks requiring precision and power. In construction, hydraulic motors enable heavy machinery to lift, dig, and move materials efficiently. In agriculture, they power equipment like harvesters and sprayers, ensuring smooth operation in challenging environments.

The compact design of hydraulic motors allows them to fit into tight spaces, making them ideal for mobile applications. Their ability to deliver consistent torque under varying loads ensures reliable performance, even in rugged terrains. Operators benefit from the motors' durability and adaptability, which reduce downtime and enhance productivity.

Specialized Uses in Marine and Aerospace Industries

Hydraulic motors excel in specialized applications within marine and aerospace industries. In marine environments, these motors power bow thrusters, enabling precise maneuvering of ships in confined spaces. Their robust construction withstands corrosive saltwater conditions, ensuring long-term reliability.

In aerospace, hydraulic motors contribute to critical systems such as landing gear and flight control mechanisms. The market for hydraulic motors in these industries is projected to grow significantly. By 2033, the market size is expected to reach USD 1.8 billion, with a compound annual growth rate (CAGR) of 5.5% from 2026 to 2033. The aerospace sector alone is forecasted to have over 38,000 commercial aircraft by 2039, contributing $1 trillion to the U.S. economy by 2025.

| Metric | Value |

|---|---|

| Market Size (2024) | USD 1.2 Billion |

| Forecasted Growth (CAGR 2026-2033) | 5.5% |

| Projected Market Size (2033) | USD 1.8 Billion |

| Projected Number of Commercial Aircraft by 2039 | Over 38,000 |

| Expected Contribution to U.S. Economy by 2025 | $1 trillion |

These statistics underscore the growing importance of hydraulic motors in marine and aerospace applications, where precision and reliability are paramount.

Hydraulic motors deliver unmatched power and torque, excelling in demanding applications. Their high power density, efficiency, and durability make them indispensable across industries. Compared to other systems, they offer superior performance in harsh environments. The table below highlights their key benefits:

| Benefit | Statistic |

|---|---|

| Energy Efficiency | Up to 80% more efficient than pneumatic pumps |

| Power Delivery | Great power and accuracy in operation |

| Maintenance Costs | Lower maintenance costs due to less strain |

FAQ

What determines the lifespan of a hydraulic motor?

The lifespan depends on factors like maintenance, operating conditions, and fluid quality. Regular servicing and using high-quality hydraulic fluids extend durability.

Can hydraulic motors operate in extreme temperatures?

Yes, hydraulic motors function reliably in extreme temperatures due to their robust design. Proper fluid selection ensures optimal performance in harsh environments.

How do hydraulic motors compare to electric motors in efficiency?

Hydraulic motors deliver higher efficiency in heavy-duty applications. They excel in torque output and power density, outperforming electric motors in demanding environments.

Post time: May-15-2025