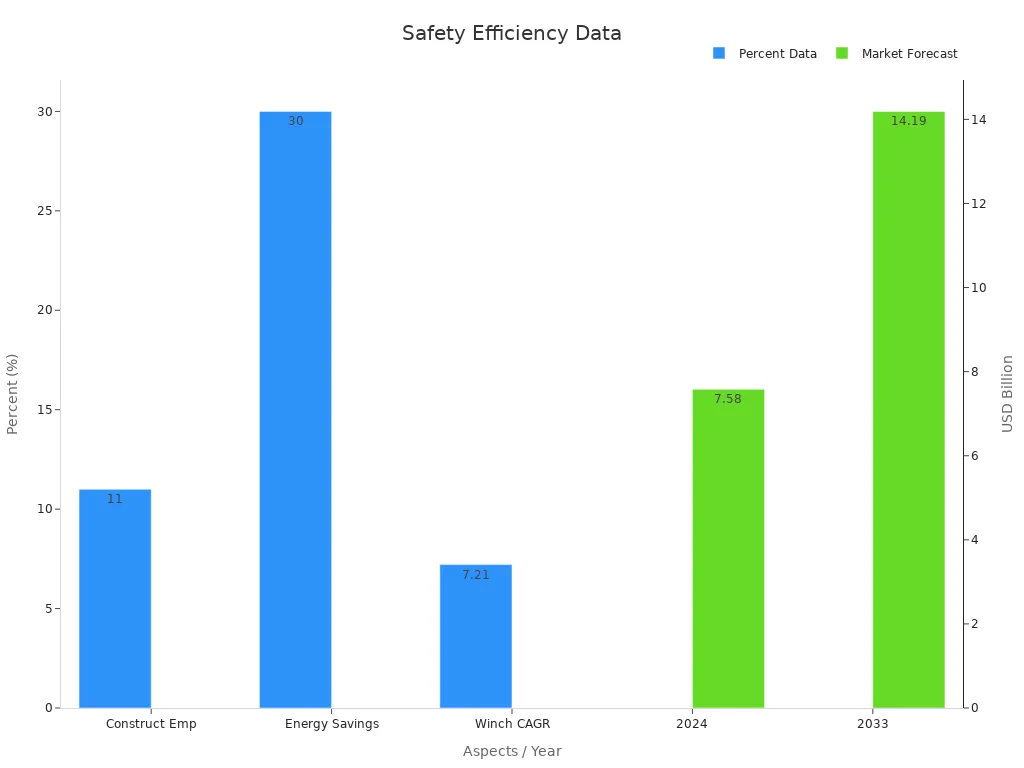

Selecting a Hydraulic Winch impacts both safety and efficiency in demanding industries. Strong market growth, projected at a 6.5% CAGR, highlights rising demand for equipment that meets strict safety standards. The chart below shows how efficiency and advanced features drive market expansion.

Evidence Aspect |

Numerical Data / Trend |

Significance to Safety and Efficiency in Hydraulic Winch Selection |

|---|---|---|

| Market Size 2023 | USD 2.5 billion | Baseline market size indicating current demand |

| Market Size Projection 2032 | USD 4.5 billion | Growth driven by demand in safety-critical industries |

| Energy Savings from Hydraulic Tech | Up to 30% energy savings due to technological advances | Enhances operational efficiency and reduces costs |

Key Takeaways

- Choose a hydraulic winch by carefully considering line pull capacity, line speed, cable size, system requirements, and key features to ensure safety and efficiency.

- Match the winch’s specifications to your load and environment, using manufacturer charts and safety margins to avoid accidents and equipment damage.

- Look for advanced features like remote controls, automatic brakes, and corrosion resistance to improve performance, reduce maintenance, and enhance operator safety.

Hydraulic Winch Line Pull Capacity

Definition of Line Pull Capacity

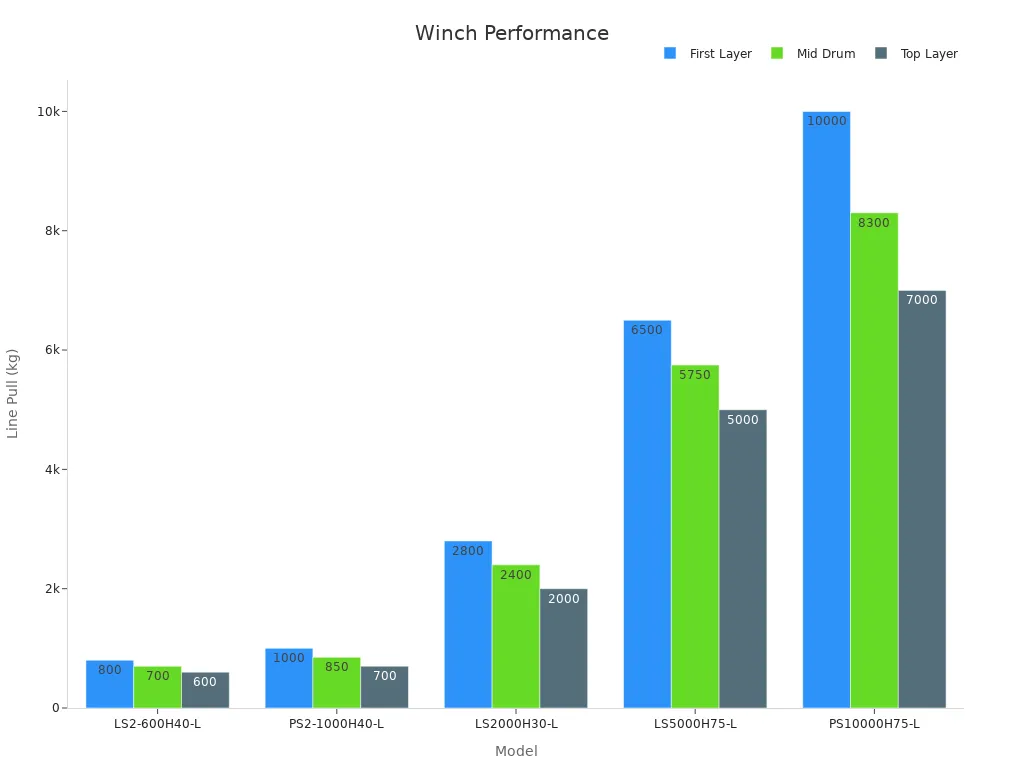

Line pull capacity describes the maximum force a winch can exert on a load through its cable. Manufacturers determine this value based on the safe working load of the wire rope and the winch’s mechanical design. The first layer of rope on the drum provides the highest line pull, while each additional layer reduces this capacity. For example, a 3/4" wire rope increases the drum diameter by 1.5" with each layer, which raises the torque needed to maintain the same pull. Hydraulic pressure and motor efficiency set the upper limits for available torque.

Importance for Load Handling

Operators rely on accurate line pull ratings to ensure safe and efficient load handling. The line pull must overcome friction, the weight of the load, and any environmental resistance. The basic formula for calculating required line pull is:

P = F + (μ * W)

where P is the total pull, F is the force to overcome friction, μ is the friction coefficient, and W is the weight of the object. Real-world conditions, such as wind or uneven terrain, can increase these demands. Manufacturers often provide detailed load charts to help users match winch capacity to their application.

Model |

First Layer (kg/lb) |

Mid Drum (kg/lb) |

Top Layer (kg/lb) |

|---|---|---|---|

| LS2-600H40-L | 800 (1,750) | 700 (1,535) | 600 (1,320) |

| PS2-1000H40-L | 1,000 (2,200) | 850 (1,870) | 700 (1,540) |

| LS2000H30-L | 2,800 (6,200) | 2,400 (5,300) | 2,000 (4,400) |

| LS5000H75-L | 6,500 (14,330) | 5,750 (12,665) | 5,000 (11,000) |

| PS10000H75-L | 10,000 (22,000) | 8,300 (18,290) | 7,000 (15,430) |

Note: Line pull capacity decreases as more rope layers are added to the drum.

How to Select the Right Line Pull

Selecting the correct line pull capacity starts with calculating the minimum requirement. Industry best practice suggests multiplying the gross vehicle weight rating (GVWR) by 1.5. For challenging conditions, such as steep slopes or mud, increase this value by 25-50%. Additional equipment or modifications may require further adjustments. For complex recovery tasks, advanced calculations involving load weight and terrain resistance provide greater accuracy. Operators should always reference manufacturer load charts and consider safety margins to ensure reliable performance from their Hydraulic Winch.

Hydraulic Winch Line Speed

What Is Line Speed

Line speed refers to how quickly the winch cable moves in or out during operation. Manufacturers measure line speed in meters per minute (m/min). This value shows how fast the winch can pull or release the load. The industry uses meters per minute for speed and pounds or kilograms for line pull. Both ratings are based on the first layer of wire rope on the drum, which provides the most accurate baseline for performance.

Productivity and Application Impact

Line speed plays a key role in the productivity of a Hydraulic Winch. Faster line speeds allow operators to complete lifting or pulling tasks more quickly. The hydraulic pump’s flow capacity, measured in gallons per minute (GPM), directly affects how fast the winch operates. When the pump delivers more fluid, the winch cable moves faster. However, higher speeds can increase energy use and mechanical stress. Operators must balance speed with the need for safe and reliable operation. Matching the pump’s GPM and shaft speed (RPM) to the system ensures efficient power transfer and reduces wear.

Tip: Always check the hydraulic system’s flow and pressure ratings before selecting a winch to avoid inefficiency or damage.

Choosing the Appropriate Line Speed

Selecting the right line speed depends on the application’s needs and the winch’s performance data. Operators should review key parameters to make an informed choice:

Parameter |

Value |

|---|---|

| Maximum Line Pull | 30,000 pounds |

| Line Speed | 14.7 feet per minute |

| Motor Displacement | 12 and 14.9 cubic-inch motors |

| Gear Reduction Ratio | 36:1 |

| Brake Type | Spring-applied disc brake |

These factors influence how quickly and safely the winch can move loads. Operators should consider both the required speed and the load weight to ensure the winch meets the demands of the job.

Hydraulic Winch Cable Capacity and Diameter

Understanding Cable Capacity and Diameter

Cable capacity refers to the maximum length and size of wire rope that a winch drum can hold. Diameter measures the thickness of the cable. Both factors affect the strength and performance of a Hydraulic Winch. A thicker cable can handle heavier loads, but it takes up more space on the drum. Manufacturers provide charts that show how much cable fits on each drum size. Operators should check these charts before choosing a cable.

Safety and Application Considerations

Safety depends on using the correct cable diameter and capacity. A cable that is too thin may snap under heavy loads. A cable that is too thick may not fit properly on the drum. Operators must match the cable to the winch’s rated line pull and the job’s requirements. For example, lifting heavy construction materials needs a strong, thick cable. Pulling lighter loads may allow for a thinner cable. Always inspect cables for wear, fraying, or damage before use.

Tip: Replace cables at the first sign of damage to prevent accidents and equipment failure.

Selecting the Best Cable for Your Needs

Choosing the right cable involves several steps:

- Identify the maximum load for your application.

- Check the winch drum’s cable capacity and recommended diameter.

- Select a cable with a safety factor of at least 1.5 times the maximum load.

- Consider the environment—marine, construction, or industrial settings may require special coatings or materials.

A careful selection process ensures the Hydraulic Winch operates safely and efficiently in any application.

Hydraulic Winch System Requirements

Hydraulic Pressure and Flow Basics

Hydraulic winches rely on the right balance of pressure and flow to operate smoothly. Pressure measures the force that moves the hydraulic fluid, while flow measures how much fluid moves through the system each minute. Both values must match the winch’s design. Too little pressure or flow can cause slow or weak operation. Too much can damage components. Operators should always check the manufacturer’s specifications for recommended pressure and flow rates.

Ensuring System Compatibility

System compatibility ensures that the hydraulic power unit, hoses, and controls work together with the winch. In large-scale offshore projects, such as the Linear Winch Middle East case, engineers designed custom hydraulic power units to match the winch’s needs. This careful integration allowed for continuous pulling and smooth operation. The winch’s gripper cycles depended on precise hydraulic control. In another example, a winch durability test system used custom power units and control skids. These systems included load-sensing pumps and adaptable heat exchangers. Such tailored solutions improved reliability and allowed for detailed performance analysis.

Assessment Tips for Hydraulic Systems

Operators can follow several best practices to assess hydraulic systems:

- Use a three-stage maintenance approach: fault identification, diagnosis, and prognosis.

- Apply real-time condition monitoring systems to detect early signs of wear.

- Analyze sensor data using time and frequency domain methods, such as Fourier transforms and Kalman filters.

- Employ predictive analytics and machine learning models to estimate remaining useful life.

These steps help maintain the Hydraulic Winch in top condition and reduce unexpected downtime.

Hydraulic Winch Features and Functions

Essential Winch Features

Modern hydraulic winches include several features that improve safety, efficiency, and durability. Manufacturers design these winches with high load capacities, often handling between 10 and 25 tons. They use robust hydraulic systems to distribute force evenly. Operators benefit from variable-speed controls and automatic braking systems, which help manage power use and reduce wear. Many winches use corrosion-resistant materials, such as stainless steel and protective coatings, to withstand harsh environments. Advanced safety features, including load limiters, pressure sensors, and emergency stop systems, protect both operators and equipment. The table below highlights key performance metrics that demonstrate the operational benefits of advanced winch features:

Performance Metric |

Value / Description |

|---|---|

| Lifting Rating | 5:1 ratio, indicating load capacity for lifting operations |

| Pulling Rating | 3.5:1 ratio, indicating load capacity for pulling operations |

| Operational Pressure | 6.3 bar (90 psi), ensuring consistent hydraulic performance |

| Fuel Savings | Up to 25% reduction due to variable displacement pump technology |

| Emissions Reduction | Approximately 30% lower emissions with advanced pump systems |

| Heat Generation | Significantly reduced, leading to less energy loss and longer component lifespan |

| Maintenance Costs | Decreased due to reduced wear and less frequent oil/filter changes |

| Operational Efficiency | Improved through precise flow control and load sensing features |

Drum Release and Control Options

Hydraulic winches offer advanced drum release and control options to enhance operational safety. Fail-safe wet disc brakes and automatic drum brakes ensure secure operation under demanding conditions. Drum locks and oversized drum barrels help maintain wire rope longevity and secure handling. Operators can use remote throttle valves for variable speed and safe load control. Auxiliary brake release systems allow precise lowering, preventing uncontrolled drum release. Many winches also include slack rope detection, which triggers automatic safety shutoff to prevent unsafe operation. Control electronics with functional safety features and data logging further improve monitoring and operator awareness.

Tip: Remote control systems allow operators to manage winching operations from a safe distance, reducing risk in hazardous environments.

Customization and Additional Functions

Manufacturers offer a wide range of customization options to meet specific operational needs. Winches can feature single or double drums, multiple control stations, and upgraded electronics such as line tension monitoring and proximity sensors. Enhanced drum configurations and motor upgrades provide higher pulling capacity and better performance. Corrosion resistance enhancements, such as special coatings, extend winch life in marine environments. Many winches now integrate smart technologies for remote monitoring, predictive maintenance, and automation. These features help reduce workplace accidents and improve energy efficiency. The table below summarizes key customization enhancements:

Customization Option / Enhancement |

Description / Performance Impact |

|---|---|

| Compact and Lightweight Design | Reduces size and weight, improving installation and space optimization. |

| Enhanced Load Capacity | High-pressure pumps and valves enable heavier load handling with precise control. |

| Precise Control and Automation | Electronic controls and sensors allow variable speed, load sensing, and position feedback. |

| Safety Features and Systems | Overload protection, emergency stops, and real-time monitoring enhance safety. |

| Remote Control and Monitoring | Wired/wireless systems provide real-time data, increasing safety and efficiency. |

| Integration with Telemetry Systems | Centralized control and data exchange enable predictive maintenance and optimized lifespan. |

Selecting the right Hydraulic Winch involves careful review of line pull, speed, cable, system requirements, and features.

- Overload incidents drop by 90% with proper force monitoring.

- Real-time load indicators and remote controls improve safety and efficiency.

- Certified equipment ensures reliable operation in harsh conditions.

FAQ

What industries use hydraulic winches most often?

Hydraulic winches see frequent use in construction, marine, mining, and oil and gas industries. These sectors require reliable lifting and pulling equipment for heavy-duty tasks.

How often should operators inspect hydraulic winches?

Operators should inspect hydraulic winches before each use. Regular checks help identify wear, damage, or leaks, ensuring safe and efficient operation every time.

Tip: Schedule monthly maintenance for optimal performance and longer equipment life.

Can hydraulic winches operate in extreme environments?

Yes. Manufacturers design hydraulic winches with corrosion-resistant materials and sealed components. These features allow reliable operation in harsh weather, marine, or dusty conditions.

Post time: Jun-18-2025