INI Hydraulic, a well - known manufacturer in the hydraulic field, with over 30 years of technological accumulation, provides highly customized hydraulic winches and complete electro - hydraulic solutions for global customers. The following are representative customization cases and their technical highlights:

1. Heavy - duty Winches for Offshore Oil Drilling Platforms

Requirement Background

Offshore operations demand large tonnage, high reliability, precise control, as well as corrosion and rust resistance.

INI's Solution

- Developed the IYJ - N series of hydraulic winches, equipped with screws treated with Dacromet surface treatment, salt - fog resistant coatings, and explosion - proof designs.

- Integrated an intelligent feedback system to monitor the length, speed, and tension of the cable in real - time.

Results

Increased the operating efficiency of offshore drilling platforms by 30% and reduced the failure rate by 45%.

2. Free - fall Winches for Cranes in Rugged Terrains

Customer Requirements

Cranes need to quickly release cables in complex terrains to shorten the lifting time.

Customized Solution

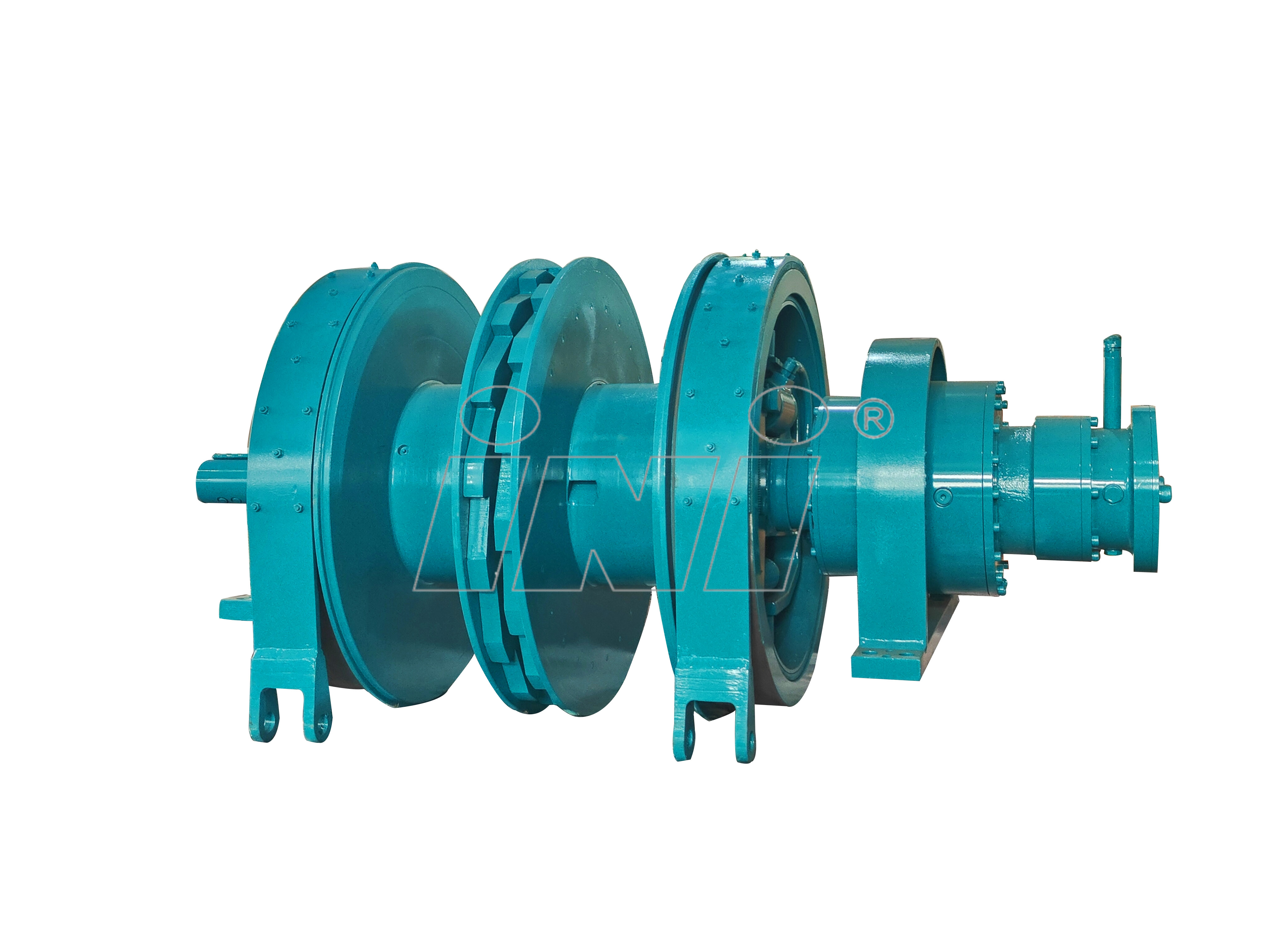

- Launched the IYJ - L free - fall winch, supporting dual - mode operation (hydraulic drive + gravity free - fall).

- Optimized the structure of the planetary gearbox to complete the full release of the cable within 5 seconds.

Application Effects

Adapted to cranes of brands such as SANY, shortening the operation cycle by over 20%.

3. Planetary Reducers for Ferris Wheels

Challenges

Large - scale amusement facilities require smooth start - stop and high safety. Traditional gearboxes are prone to causing jitters.

Technological Breakthroughs

- Customized the IGC - T series of planetary gearboxes, using modular design to reduce space occupation.

- Employed silent electric motors to ensure noise - free operation of the Ferris wheel.

Case Results

Applied to landmark Ferris wheel projects in multiple cities, achieving a zero - accident safety record.

4. Large - capacity Hydraulic Systems for Dredgers

Industry Pain Points

River dredging needs to handle sediment at a rate of 120m³/h - 1000m³/h, and traditional systems consume excessive energy.

Customized Design

- Developed modular hydraulic power units that support on - demand flow adjustment.

- Used IPM series high - torque motors to adapt to long - term continuous operation.

Benefits

Reduced energy consumption by 18% and extended the maintenance cycle to 5000 hours.

5. Positioning Winches for Ocean - going Ships

Scenario Requirements

Ships need to stably retract and release anchors in ports or at sea, requiring high load - bearing capacity to resist the impact of tides and waves.

Solution Highlights

- The IYJ - C series of mooring and positioning winches are equipped with high - load - bearing band brakes.

- Increased the pressure resistance level of the hydraulic system to 35MPa to ensure anchor lifting and dropping under various marine environmental conditions.

Customer Feedback

Listed as standard - configuration products by several European shipping companies.

Why Choose INI Hydraulic's Customization Services?

- Certification Assurance: An ISO - standard factory with full - process quality control.

- R & D Capability: It has the independent R & D and design capabilities for core components such as hydraulic motors, reducers, winches, transmission devices, and hydraulic systems.

- Global Service: Supports technical communication in multiple languages, and its cases cover more than ten fields including offshore engineering, ships, mining, and construction machinery.

Obtain Customized Solutions

If you need to learn more about cases or submit requirements, please contact:

- Official Website: INI Hydraulic product page

- Email: iniexport@china - ini.com

- Phone/WhatsApp: +86 15990536851

Post time: May-28-2025