Hydraulic winches deliver greater pulling power and torque compared to an electric winch, thanks to their continuous operation and higher load capacity. They draw power from hydraulic systems, allowing them to move heavy loads without overheating. This strength makes the choice of winch essential for demanding applications.

Key Takeaways

- Hydraulic winches provide stronger, continuous pulling power and work well in heavy-duty, harsh environments where reliability matters most.

- Electric winches offer precise control, quieter operation, and easier installation, making them ideal for lighter tasks and places with good electrical power.

- Choosing the right winch depends on your load needs, operating conditions, and maintenance ability; always pick a winch rated at least 1.5 times your heaviest load for safety.

Winch Strength: What It Means

Pulling Power and Torque

Pulling power and torque form the foundation of winch performance. Manufacturers and industry professionals use these metrics to evaluate how much force a winch can exert and how efficiently it can move heavy loads. Torque, measured in Newton-meters or foot-pounds, directly relates to the winch drum's ability to rotate and pull a load. For example, a professional winch may deliver up to 120,000 foot-pounds of torque and line pull capacities ranging from 10,000 to 30,000 pounds. These figures highlight the robust capabilities required in construction, mining, and marine operations.

Standard metrics also include motor horsepower and gear ratios. A higher gear ratio, such as 355:1, increases torque at the drum, enhancing pulling power. Studies show that for heavy loads, an electro-hydraulic composite drive winch system can achieve up to 45 kW of output power and 120 N·m of torque. These values ensure reliable performance in demanding environments.

Note: Pulling force decreases as more cable layers wrap around the drum, reducing the effective torque-to-force conversion.

Load Capacity

Load capacity defines the maximum weight a winch can safely handle. Industry statistics reveal that medium-duty winches, with capacities between 3,000 and 10,000 pounds, dominate the market due to their versatility. Heavy-duty models, capable of lifting over 10,000 pounds, serve critical roles in mining and heavy vehicle recovery.

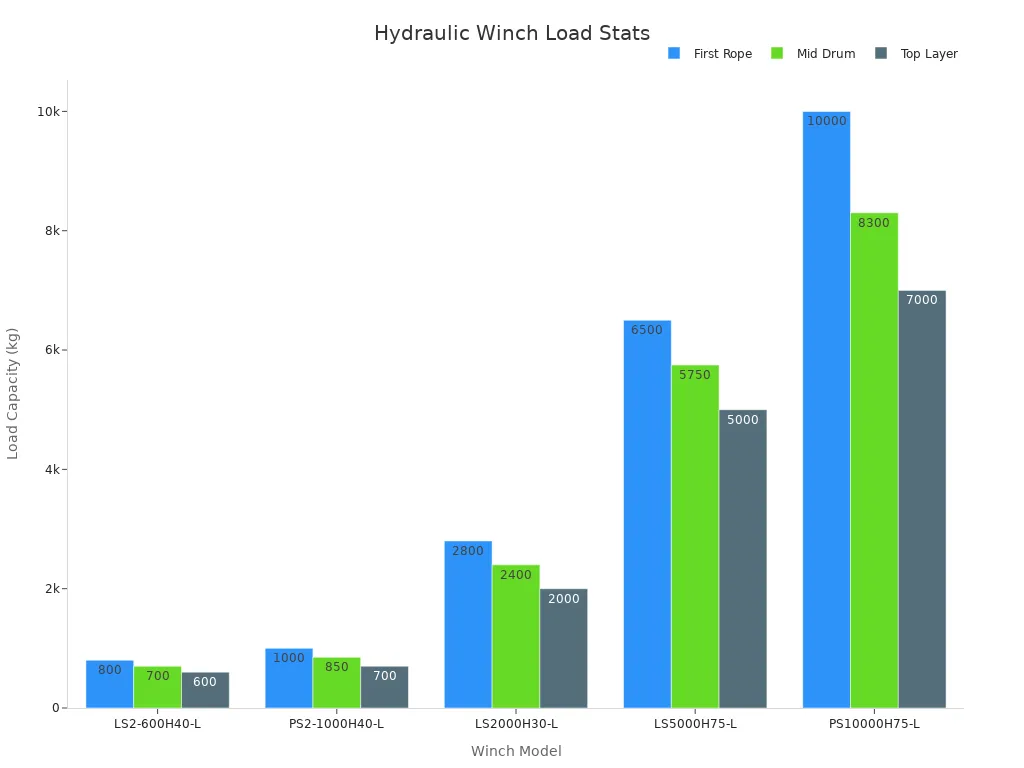

The following table demonstrates typical load capacities for hydraulic winches:

| Hydraulic Winch Model | Load Capacity on First Rope Layer (kg/lb) | Load Capacity on Mid Drum (kg/lb) | Load Capacity on Top Layer (kg/lb) |

|---|---|---|---|

| LS2-600H40-L | 800 (1,750) | 700 (1,535) | 600 (1,320) |

| PS2-1000H40-L | 1,000 (2,200) | 850 (1,870) | 700 (1,540) |

| LS2000H30-L | 2,800 (6,200) | 2,400 (5,300) | 2,000 (4,400) |

| LS5000H75-L | 6,500 (14,330) | 5,750 (12,665) | 5,000 (11,000) |

| PS10000H75-L | 10,000 (22,000) | 8,300 (18,290) | 7,000 (15,430) |

These values confirm that hydraulic winches consistently deliver high load capacities, making them suitable for the most demanding applications.

Hydraulic Winch: Power and Performance

How Hydraulic Winches Work

Hydraulic winches use pressurized fluid to generate mechanical energy. A hydraulic pump sends oil to a motor, which then rotates the drum. This drum winds or unwinds the cable, creating tension to move heavy loads. Gear trains amplify the torque from the motor, allowing the winch to pull much heavier loads than the motor alone could handle. Safety features such as brakes and ratchets prevent accidental cable release and improve load control. This system provides high torque at low speeds, making hydraulic winches ideal for precise and heavy-duty operations.

Typical Load Ratings

Technical studies show that hydraulic winches deliver consistent pulling power and high torque, even under extreme loads. The following table highlights key performance differences between hydraulic and electric winches in heavy-load environments:

| Feature / Aspect | Hydraulic Winches | Electric Winches |

|---|---|---|

| Power-to-Size Ratio | High; compact with high torque | Larger motors needed for high torque |

| Output Force & Torque | Very high, consistent under heavy loads | May slow down under heavy loads |

| Reliability under Load | No power loss while holding load | Dependent on reliable power source |

| Performance in Harsh Environments | Durable and reliable in extreme conditions | Sensitive to water, dust, and contaminants |

Hydraulic winches maintain their performance in harsh environments and provide reliable operation during continuous use.

Best Applications

Hydraulic winches excel in demanding environments that require continuous, heavy-duty operation. They are optimal for:

- Marine and offshore industries, where corrosion resistance and stable performance are critical.

- Construction and industrial settings, for moving heavy machinery and materials.

- Rescue, mining, and tunneling, where reliability and continuous operation are essential.

Field data shows hydraulic winches can operate for thousands of hours without performance loss and offer superior torque and lifespan compared to electric models.

Electric Winch: Capabilities and Limits

How Electric Winches Work

Electric winches convert electrical energy into mechanical motion. The system uses a motor-driven drum to wind a cable or rope, pulling or lifting loads. Key electrical components include AC or DC motors, with DC motors often powered by batteries. Mechanical parts such as the drum, cable system, and gear system with high gear ratios control speed and power. Pulley blocks can improve lifting efficiency. Modern electric winches often feature variable speed control and built-in brakes for enhanced safety. Regular maintenance of both electrical (motor, wiring, control systems) and mechanical parts (cables, lubrication) ensures reliable performance.

Tip: Brushless DC motors offer higher efficiency, better speed control, and improved durability compared to traditional brushed motors.

Typical Load Ratings

Industry experts recommend selecting an electric winch with a load rating at least 1.5 times the gross vehicle weight or the heaviest load to be hauled. Typical electric winch capacities range from 2,000 to 13,000 pounds. For example:

- Winches rated between 9,000 and 12,000 pounds suit SUVs, trucks, and Jeeps.

- Actual capacity depends on cable layers, terrain, weather, and load conditions.

- Real-world factors such as mud, steep hills, or longer rope lengths may require higher capacity.

Best Applications

Electric winches have gained popularity due to advancements in materials and smart technologies. They excel in applications requiring precise control and high responsiveness. Common uses include:

- Vehicle recovery and off-road adventures

- Industrial automation and remote-controlled lifting

- Situations where energy efficiency and environmental benefits are priorities

The integration of sensors, automation, and remote operation has expanded their role in modern industries. Safety regulations and technological improvements continue to drive their adoption.

Winch Comparison: Hydraulic vs. Electric

Strength and Performance

Hydraulic winches deliver superior strength and consistent performance, especially in heavy-duty and continuous operations. They maintain high torque and pulling power even under extreme loads. Electric winches, on the other hand, offer precise control and quiet operation, making them suitable for lighter tasks and environments where noise matters. Operators often choose hydraulic winches for industrial and commercial applications that demand uninterrupted power and high load capacity. Electric winches excel in scenarios requiring intermittent use and advanced control features.

- Hydraulic winches provide:

- High and consistent output force

- Reliable performance in harsh conditions

- Faster line speeds compared to electric models

- Electric winches offer:

- Precise control and variable speed options

- Clean and quiet operation

- Dependence on available electrical power

Note: The choice between hydraulic and electric winches depends on the required strength, duty cycle, and environmental conditions.

Power Source and Operation

The power source significantly impacts winch operation and efficiency. Hydraulic winches use a single hydraulic pump to power multiple units, which increases operational efficiency in large-scale setups. These winches achieve mechanical efficiency rates up to 90% for planetary types and support smooth, proportional control for precise movements. Electric winches rely on individual electric motors, which simplifies installation but limits mechanical efficiency and line speed.

| Feature/Aspect | Hydraulic Winches | Electric Winches |

|---|---|---|

| Power Source | Single hydraulic pump for multiple units | Individual electric motor per winch |

| Mechanical Efficiency | Up to 90% (planetary type) | Lower, especially in fixed speed systems |

| Control | Smooth, proportional electronic valves | Variable frequency drives (higher cost) |

| Line Speed Capability | 3-5x faster than wormgear electric models | Limited by motor and cooling |

| Maintenance | Regular hydraulic system checks | Simpler, less frequent maintenance |

| Noise/Environmental Impact | Hydraulic noise, potential leaks | Quieter, cleaner operation |

Hydraulic winches suit environments where electric power is unavailable or hazardous, while electric winches fit locations with reliable electrical infrastructure.

Installation and Setup

Installation complexity varies greatly between hydraulic and electric winches. Hydraulic winches require integration with a vehicle’s hydraulic system, which increases installation time and complexity. This process often involves connecting to the power steering system and ensuring proper hydraulic fluid management. Electric winches, in contrast, feature a simpler setup. Technicians can mount them directly and connect them to a battery, making them ideal for smaller vehicles and do-it-yourself installations.

| Aspect | Hydraulic Winches | Electric Winches |

|---|---|---|

| Installation Complexity | Integration with hydraulic system; more complex and time-consuming | Simpler, direct mounting and battery connection |

| Operational Dependency | Requires engine running; not usable if engine stalls | Operates independently of engine; powered by battery |

| Setup Recommendations | Select capacity 1.5–2x vehicle weight; consider terrain and rope length | Same capacity rule; focus on electrical connections and rope maintenance |

Tip: Always match the winch capacity to the vehicle’s weight and intended use for optimal safety and performance.

Maintenance and Durability

Maintenance schedules and durability differ between hydraulic and electric winches. Hydraulic winches demand regular inspection of hydraulic lines, fluid levels, and control systems. Environmental factors such as oil leaks and cooling system wear require frequent attention. Electric winches benefit from integrated heat dissipation and advanced electronic controls, which reduce wear and maintenance downtime.

- Inspect winches daily for visible damage and cable condition.

- Lubricate weekly and check brake and clutch operation.

- Conduct monthly inspections of bolts, fasteners, gearbox, and motor.

- Schedule annual professional servicing to prevent major failures.

Hydraulic winches offer long-term durability but require more intensive maintenance. Electric winches provide quieter operation, lower environmental impact, and simpler upkeep, making them attractive for users seeking reliability with less complexity.

Cost Factors

Cost considerations play a crucial role in winch selection. Hydraulic winches generally involve higher initial investment and installation costs due to their complex design and integration requirements. These winches justify their price with superior durability and continuous operation capabilities, especially in industrial settings. Electric winches present a more budget-friendly option, with lower upfront and installation costs. They also offer energy savings and long service life when maintained properly.

| Cost Aspect | Electric Winches | Hydraulic Winches |

|---|---|---|

| Initial Winch Price | Starts from a few hundred dollars | Can exceed a thousand dollars |

| Installation | Easier, less specialized labor needed | Requires professional installation and integration |

| Labor Costs | Lower due to simplicity | Higher due to complexity |

| Additional Components | Generally less complex | May require specialized parts and modifications |

| Total Cost Range | Lower end: few hundred dollars | Higher end: over a thousand dollars |

| Operating Costs | Lower power consumption, long service life | Higher maintenance and integration costs |

Advanced features such as AI integration and variable frequency drives can increase the initial cost for both types, but they also improve efficiency and reduce long-term expenses.

Choosing the Right Winch

Matching Winch Type to Your Needs

Selecting the optimal winch requires a structured approach that considers both operational demands and technical specifications. Multi-Criteria Decision Making (MCDM) frameworks, such as the Analytic Hierarchy Process (AHP), help decision-makers evaluate options by translating functional requirements into design priorities. This method allows users to balance factors like cost, maintenance, safety, and operational efficiency. For example, marine winches must comply with strict standards, including the use of machine-cut gears from steel or bronze, positive lubrication systems, and secure hardware. Operators should also ensure that all moving parts have guards and that the drum design supports even rope winding. Control options, safety features, and brand reputation play a significant role in the final selection. By applying these frameworks, users can confidently match winch type to their specific application, whether for marine, construction, or industrial use.

| Criteria Category | Key Considerations |

|---|---|

| Environmental Protection | Corrosion-resistant materials, IP66+ ingress protection, hazardous area ratings |

| Regulatory Compliance | Maritime certifications, SOLAS/IMO standards |

| System Integration | Compatibility with vessel or site management systems |

| Reliability Features | Redundant components, backup power, continuous operation capability |

| Maintenance & Support | Global service, spare parts, remote diagnostics |

| Operational Parameters | Load capacity, power source, control options, safety features |

Key Questions Before Buying

Before purchasing a winch, buyers should address several critical questions to ensure the equipment meets their needs:

- What is the required pulling capacity for the intended application?

- Does the motor provide reliable power for continuous or heavy-duty use?

- Is the construction durable, and are the materials suitable for the operating environment?

- What is the available line length, and does it match operational requirements?

- Are remote control and safety features, such as overload protection and emergency stops, included?

- Does the winch offer mounting options compatible with the intended installation?

- What warranty coverage and after-sales support does the manufacturer provide?

A common guideline recommends selecting a winch with a line-pull rating at least 1.5 times the gross vehicle weight or maximum load. This approach ensures the winch can handle demanding recovery or lifting scenarios while maintaining safety and reliability.

Hydraulic winches deliver unmatched strength for heavy-duty, continuous operations. The marine hydraulic winch market expects strong growth, reaching $850 million by 2033, as large ships require reliable, high-capacity equipment. Electric winches remain ideal for lighter, occasional tasks. Users should match winch type to strength, frequency, and installation needs.

FAQ

What makes hydraulic winches stronger than electric winches?

Hydraulic winches use pressurized fluid for continuous, high-torque output. This design allows them to handle heavier loads without overheating or losing power.

Can electric winches operate underwater or in harsh environments?

Electric winches can work in wet or dusty areas, but hydraulic winches offer better durability and reliability in extreme or underwater conditions.

How often should operators maintain a hydraulic winch?

Operators should inspect hydraulic winches daily, lubricate weekly, and schedule professional servicing annually to ensure safe and reliable operation.

Post time: Jun-20-2025