A marine-grade hydraulic winch is a robust, water-resistant device. Shipbuilders use it for heavy lifting and pulling tasks on vessels. These winches are vital for safe and efficient marine operations. Over 35% of global offshore operations rely on hydraulic winches. Nearly 60% of marine vessels use hydraulic systems for heavy-duty winches, proving their efficiency. A reliable marine hydraulic winch manufacturer provides essential equipment. An anchor winch hydraulic system supplier ensures vessel stability.

Key Takeaways

- Marine-grade hydraulic winches are strong and water-resistant. They are important for safe and efficient work on ships.

- Choosing the right winch capacity and materials is key. This prevents accidents and makes winches last longer.

- Regular checks and following rules are important. This keeps winches working well and ships safe.

Essential Features and Operational Advantages for Shipbuilders

Robust Construction and Material Selection

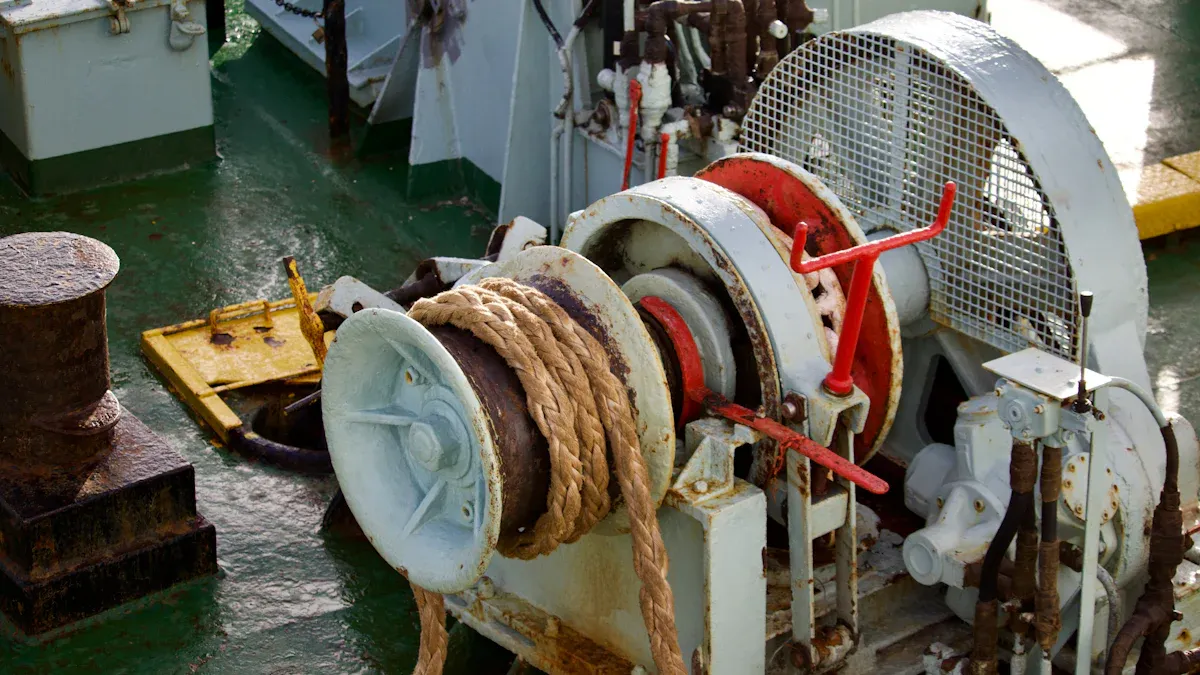

Marine-grade hydraulic winches require strong construction. They must withstand harsh marine environments. High-quality materials enhance a winch's lifespan. Corrosion-resistant steel is a key material. It performs well in saltwater conditions. The drum of a marine hydraulic winch is typically made of high-strength steel. This material withstands the immense forces involved in marine operations.

Different materials offer specific benefits. Stainless steel is more durable and corrosion-resistant. It is ideal for high-performance ocean use. Aluminum is much lighter. It suits smaller or racing boats. Chrome over bronze offers added durability and a stylish gleam.

Specific steel types also contribute to strength. Q345B Steel is chosen for its mechanical properties. It adds to the structural strength of winch components. Q235B Steel also plays a role in the overall robustness of the winch.

Material properties are crucial for durability. Corrosion resistance is vital. Stainless steel contains chromium and nickel. This blend resists rust, oxidation, and saltwater damage. It makes stainless steel ideal for marine environments. High tensile strength allows winches to manage heavy loads. It prevents distortion. This property ensures safe lifting and pulling operations. It maintains the winch's shape and power under pressure. Durability and wear and tear resistance are also important. Stainless steel's inherent durability prolongs the winch's lifespan. It minimizes the need for frequent repairs or replacements. It helps reduce the impact of regular use in strenuous work environments.

Hydraulic System Performance and Reliability

The hydraulic system forms the core of a marine winch. Its performance directly impacts operational efficiency. A hydraulic motor in a winch system can operate under 200 bar pressure. Two pumps can provide a total flow rate of 7000 L/min. Marine hydraulic winch systems typically operate at an operational pressure of 6.3 bar (90 psi). These specifications ensure powerful and consistent operation.

Reliability is paramount for marine winches. Several factors can affect it. Leakage and fluid contamination are common issues. Regular inspection and maintenance identify and fix leaks. Shipbuilders must ensure tight hydraulic connections. They should replace damaged seals or hoses. A strict fluid cleanliness regimen with regular checks and replacements is also necessary. Overheating can also occur. Install temperature sensors. Implement duty cycles. Provide adequate cooling with fans or heat exchangers. Regularly check and maintain cooling systems.

Corrosion and rust pose significant threats. Regularly inspect for corrosion. Apply corrosion-resistant coatings. Perform routine cleaning. Consider stainless steel or other corrosion-resistant materials. Inadequate lubrication leads to wear. Establish a regular lubrication schedule based on manufacturer recommendations. Ensure all moving parts receive adequate lubrication. Monitor lubrication levels. Mechanical component wear, such as gears, bearings, and brake systems, also needs attention. Regularly inspect and replace worn or damaged mechanical components. Implement a proactive maintenance schedule. Follow manufacturer guidelines for replacement. Maintain a spare parts inventory. A reputable marine hydraulic winch manufacturer designs systems to minimize these failure modes.

Advanced Control and Safety Mechanisms

Modern marine hydraulic winches feature advanced control systems. These systems enhance operational precision and safety. Electrical Control Packages are common. They include electrohydraulic controls and fully electric controls. These systems offer precise command over winch functions. Remote Control Systems allow operation from a safe distance. This feature improves operator safety, especially during hazardous tasks.

Variable Frequency Drives (VFDs) are another important component. They allow for variable speed control. This capability provides flexibility for different operational needs. It also helps in smooth load handling.

These advanced controls also contribute to preventing operational issues. For example, they help prevent winch drift when the system is stopped. They also reduce the risk of electrical system failures. Regular inspections of electrical components are crucial. Check for loose connections, damaged wiring, or faulty sensors. Preventive maintenance, such as cleaning connections and replacing worn components, is also important. Some systems even include backup or redundant systems for added safety. These mechanisms ensure reliable and safe winch operation in demanding marine environments.

Strategic Selection and Integration: A Shipbuilder's Guide

Matching Winch Capacity to Vessel Requirements

Shipbuilders must carefully select winch capacity. This choice directly impacts vessel safety and operational efficiency. An incorrect winch capacity creates significant risks. For example, an undersized winch operates constantly at its peak. This causes the motor to overheat and burn out. Gears can strip. The boat might slide uncontrollably. This constant strain accelerates wear on internal components. It draws more electrical current.

Conversely, an oversized winch wastes resources. It adds unnecessary weight and cost. Winch-related incidents pose significant safety risks. Entanglement is a major cause of injuries and fatalities. In the Southern shrimp fleet between 2000 and 2011, 35 work-related injuries occurred. Eight fatalities involved deck winches. Loose clothing became entangled in 41% of these cases. Injuries often resulted in severe outcomes. These included amputations and death from mechanical asphyxiation by winch cables. Working alone on deck and entanglement in the winch drum were risk factors for fatal outcomes. These incidents highlight extreme hazards. They lead to permanent disabilities and deaths.

Shipbuilders determine the required winch capacity through a systematic methodology:

- They determine maximum environmental forces. These include wind, waves, and current.

- They evaluate mooring line tension under these forces. This considers geometry and the catenary effect.

- They apply safety factors. These factors base on regulations or industry standards.

- They account for dynamic effects. These include sudden gusts or vessel movements.

- They ensure compliance with relevant regulations and classification societies.

- They consider operational contingencies and future-proofing. This means selecting a slightly higher capacity.

Choosing a winch with capacity significantly above the minimum required, for example, 1.5 times the gross weight, ensures efficient motor operation. This leads to smoother pulls and cooler operation. It reduces strain on the entire system. This includes the battery and gears. This "over-specification" is an investment in reliability, longevity, and safety.

Material Durability and Corrosion Resistance

Marine environments are extremely harsh. They demand exceptional material durability and corrosion resistance for winches. Saltwater, humidity, and constant exposure to elements accelerate material degradation. Shipbuilders must choose materials that withstand these conditions.

Different materials offer varying levels of performance and limitations:

| Material | Performance | Limitations | Applications |

|---|---|---|---|

| Stainless Steel (316/316L) | Excellent corrosion resistance in various marine environments, especially against pitting and crevice corrosion due to molybdenum content. | Susceptible to crevice corrosion in stagnant seawater or underfouling. Not ideal for continuous immersion in highly corrosive conditions. | Marine hardware, railings, fasteners, boat fittings, offshore platforms (above waterline). |

| Duplex Stainless Steel (e.g., 2205, 2507) | Superior corrosion resistance and higher strength than austenitic stainless steels. Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. | Can be more challenging to weld and fabricate than austenitic grades. Higher cost. | Propeller shafts, pumps, valves, heat exchangers, subsea equipment, chemical tankers. |

| Super Duplex Stainless Steel (e.g., 2507) | Even higher corrosion resistance and strength than standard duplex. Designed for extreme marine environments. | Very high cost, specialized welding procedures required. | Deep-sea applications, highly corrosive chemical processing, critical offshore components. |

| Nickel-Aluminum Bronze (NAB) | Good corrosion resistance, high strength, and excellent erosion resistance. Forms a protective oxide layer. | Susceptible to dealuminification in stagnant or low-velocity seawater. Can suffer from crevice corrosion. | Propellers, pump impellers, valves, heat exchanger components, marine fasteners. |

| Copper-Nickel (Cu-Ni) Alloys (e.g., 90/10, 70/30) | Excellent resistance to biofouling and general corrosion in seawater. Good ductility and weldability. | Lower strength compared to stainless steels and NAB. Can be susceptible to impingement corrosion at high flow rates. | Seawater piping systems, heat exchangers, desalination plants, offshore firewater systems, hull cladding. |

| Titanium and Titanium Alloys | Outstanding corrosion resistance in all marine environments, including high-velocity and high-temperature seawater. Excellent strength-to-weight ratio. | Very high cost, difficult to fabricate, susceptible to hydrogen embrittlement in certain conditions. | Submersibles, heat exchangers, offshore risers, critical components in naval vessels, deep-sea equipment. |

| Aluminum Alloys (e.g., 5000 and 6000 series) | Good corrosion resistance due to the formation of a passive oxide layer. Lightweight. | Susceptible to galvanic corrosion when in contact with dissimilar metals. Can suffer from pitting in stagnant seawater. | Boat hulls, superstructures, marine ladders, gangways, offshore platform components (non-critical). |

| Carbon Steel | Poor corrosion resistance in marine environments. Rapid rusting and degradation. | Requires extensive protective coatings (paint, galvanizing) to prevent corrosion. | Structural components (with heavy protection), anchors (sacrificial), non-critical, short-term use. |

| Galvanized Steel | Improved corrosion resistance over bare carbon steel due to zinc coating acting as a sacrificial anode. | Zinc coating wears away over time, especially in abrasive or high-flow conditions. | Marine structures, docks, piers, boat trailers, fencing, some fasteners. |

| Monel (Nickel-Copper Alloy) | Excellent corrosion resistance in a wide range of marine environments, including high-velocity seawater and brackish water. Good strength and ductility. | High cost, can be susceptible to stress corrosion cracking in certain conditions. | Propeller shafts, pump components, valves, fasteners, marine instrumentation. |

Beyond the base material, effective corrosion-resistant coatings and treatments further enhance winch longevity. These coatings provide an additional layer of protection against the elements.

| Product | Grade/Type | Key Features | Recommended Applications for Winch Components & Marine Use |

|---|---|---|---|

| Consol Oil | M3 | Slower penetration, long-lasting protection, does not gum up moving parts, extended life when exposed to elements | Deck winches, anchor windlasses, capstans, steering engines, all other deck machinery |

| Consol Oil | M4 | Maximum preservation, stop-corrosion action, does not congeal or emulsify in water | Winch platforms, chain lockers, floor plates, spare parts, and other marine equipment stored for extended periods |

| Apexior | Number 3 | Low-cost basic corrosion protection for frequently wet/immersed metal surfaces (up to 140 F) | Chain lockers, condensers, air receiver tanks, brine tanks, rudders and rudder posts, propeller blades and cones |

| Apexior | Number 1 | Heat-resistant coating for metal surfaces immersed in boiling water (up to 700 F) | Water-side surfaces of steam generator boilers, drums, economizers, water heaters, evaporators, steam turbine rotors (not directly for winches but for general marine equipment) |

A reputable marine hydraulic winch manufacturer often advises on the best material and coating combinations. They ensure optimal performance and lifespan for specific vessel applications.

Seamless Integration with Ship Systems

A marine hydraulic winch does not operate in isolation. It forms an integral part of the vessel's overall operational system. Shipbuilders must ensure seamless integration. This involves mechanical, electrical, and hydraulic connections. Proper integration guarantees the winch functions efficiently and safely within the ship's infrastructure.

Mechanical integration includes secure mounting and structural reinforcement. The ship's deck or frame must support the winch's weight and operational forces. Engineers design the mounting points to distribute stress effectively. This prevents damage to the vessel structure.

Electrical and hydraulic compatibility are critical for performance. Shipbuilders must match hydraulic pressure and flow to the winch's design specifications. This prevents slow or weak operation. It also avoids component damage.

Best practices for ensuring electrical and hydraulic compatibility include:

- Match hydraulic pressure and flow to the winch's design specifications. This prevents slow or weak operation or component damage.

- Ensure the hydraulic power unit, hoses, and controls are compatible with the winch system.

- Check the manufacturer’s specifications for recommended pressure and flow rates.

- Consider custom hydraulic power units and control skids for large-scale or specialized projects. This ensures precise control and reliability.

A marine hydraulic winch manufacturer often provides detailed specifications and support for integration. They help shipbuilders achieve optimal system performance. This ensures the winch operates harmoniously with other vessel components.

Maintenance, Longevity, and Regulatory Compliance with a Marine Hydraulic Winch Manufacturer

Shipbuilders understand that a marine hydraulic winch represents a significant investment. Protecting this investment requires diligent maintenance, strategic planning for longevity, and strict adherence to regulatory standards. A proactive approach ensures operational reliability and safety throughout the winch's service life. Partnering with a knowledgeable marine hydraulic winch manufacturer can streamline these processes.

Best Practices for Winch Maintenance

Effective maintenance practices are crucial for the continuous, reliable operation of marine winches. Regular checks prevent minor issues from escalating into costly failures. Shipbuilders implement a structured maintenance schedule.

- Daily Inspections: Before and after each use, personnel inspect the winch for any signs of damage. They look for cracks, bends, or corrosion. They also check the cable for kinks or fraying. For hydraulic systems, they monitor the hydraulic oil level using the oil level window or dipstick. The oil level must remain within the safe range. They test oil quality by observing its clarity; it should appear amber. If the oil looks turbid, black, or emulsified, they sample and test it immediately. Personnel identify abnormal odors at the tank breather valve; a burnt odor suggests excessive oil temperature or metal contamination. They visually inspect leak-prone areas such as pipe threaded joints, cylinder piston rod seals, and pump body mating surfaces.

- Weekly/Monthly Maintenance: These intervals require more detailed attention. Personnel lubricate the winch according to the manufacturer's instructions. They check the brake and clutch operation to ensure proper function. A more thorough inspection of the winch occurs monthly. They check bolts and fasteners to ensure tightness. They inspect the gearbox and motor for any signs of wear or tear. Lubrication extends to all moving parts, such as bearings and gears, as per the owner's manual. If the winch uses wire rope, they lubricate the cable to prevent corrosion. After saltwater exposure, personnel rinse the winch with fresh water to remove salt and debris. They clean the drum and cable guides to prevent dirt buildup. They tighten loose hose clamps and immediately replace damaged hoses. They also check seals around the motor and valves for wear or leaks.

These systematic checks ensure the winch remains in optimal condition, preventing unexpected downtime and extending its operational life.

Maximizing Winch Lifespan and Performance

Maximizing a marine hydraulic winch's lifespan and performance goes beyond routine maintenance. It involves a holistic approach encompassing proper operation, quality components, and timely interventions. Shipbuilders ensure operators receive comprehensive training. This training covers correct operating procedures, load limits, and emergency protocols. Overloading a winch places undue stress on its components, accelerating wear and increasing the risk of failure. Operators must always adhere to the winch's rated capacity.

Using genuine spare parts and high-quality consumables, such as hydraulic fluid and lubricants, significantly impacts longevity. Inferior parts can compromise system integrity and performance. Regular professional servicing by qualified technicians identifies potential issues before they become critical. These experts can perform complex diagnostics and repairs, ensuring the winch operates at peak efficiency. Furthermore, protecting the winch from environmental extremes when not in use, such as covering it or storing it in a sheltered area, minimizes exposure to corrosive elements. This proactive care ensures the winch delivers consistent performance over many years.

Navigating Marine Industry Regulations

The marine industry operates under stringent international and national regulations. These rules ensure safety, environmental protection, and operational standards. Shipbuilders must navigate this complex regulatory landscape when selecting, installing, and maintaining marine winches. Compliance is not optional; it is a legal and ethical imperative.

The International Maritime Organization (IMO) frequently updates its requirements. For example, new requirements for anchor handling winches, adopted by MSC.532(107), mandate specific standards. Winches installed on or after January 1, 2026, must be designed, constructed, and installed according to classification requirements. Guidelines for these winches are available through MSC.1/Circ.1662. A thorough examination and load test must be conducted before an anchor handling winch is used. It must also be permanently marked with a Safe Working Load (SWL). Existing winches are also subject to the same examination and SWL markings. They must complete these by their first certificate renewal date in 2026.

Shipbuilders work closely with classification societies and regulatory bodies to ensure all winches meet these evolving standards. A reputable marine hydraulic winch manufacturer stays abreast of these regulations. They design their products to comply with the latest international maritime laws. This partnership helps shipbuilders avoid costly penalties and ensures the safety and legality of their vessels.

Shipbuilders must make informed decisions for winch procurement. This ensures operational excellence and safety.

- Informed Procurement: Choose wisely for vessel performance.

- Quality Winches: Guarantee smooth operations and crew safety.

- Strategic Investment: Provides lasting value and reliability.

This approach secures successful marine operations.

FAQ

What defines a marine-grade hydraulic winch?

A marine-grade hydraulic winch withstands harsh marine environments. It features robust construction and corrosion-resistant materials. It ensures reliable operation on vessels.

Why do shipbuilders prefer hydraulic winches?

Shipbuilders prefer hydraulic winches for their power, precision, and reliability. They handle heavy loads efficiently. They also offer advanced control and safety features.

How does INI Hydraulic ensure winch reliability?

INI Hydraulic ensures reliability through over 30 years of specialization. They use robust designs and quality materials. Their products undergo rigorous testing and receive positive customer feedback.

Post time: Jan-07-2026