Final drive motors and travel motors are distinct yet cooperative components in excavators. Understanding their individual roles is crucial for design and maintenance. The final drive unit is a fastest-growing segment within the global excavator track drive market, underscoring its importance. A reliable hydraulic travel motor manufacturer China is essential for any construction equipment hydraulic system OEM. Choosing the right final drive motor excavator supplier ensures optimal performance.

Key Takeaways

- The travel motor uses hydraulic power to make the excavator move. It turns fluid pressure into the spinning force that starts the tracks.

- The final drive takes power from the travel motor and makes it stronger. It slows down the spin but increases the pushing power to move the heavy excavator.

- Both parts work together for the excavator to move well. You need to pick the right parts and check them often to keep your excavator working its best.

The Travel Motor: Hydraulic Power Source

Defining the Travel Motor's Function

The travel motor serves as the primary hydraulic power source for an excavator's movement. It converts hydraulic fluid pressure and flow into mechanical rotational energy. This energy then drives the tracks, allowing the excavator to maneuver across various terrains. Without a functional travel motor, an excavator cannot move independently.

How Travel Motors Generate Motion

Travel motors generate motion through the precise interaction of hydraulic fluid and internal components. High-pressure fluid enters the motor, pushing against pistons. In axial piston motors, commonly found in excavators, these pistons extend and press against a tilted swash plate. This interaction generates a powerful rotating force. The reciprocating motion of the pistons causes the output shaft to rotate, effectively converting the fluid's linear force into rotational torque. Varying the swash plate angle allows control over the motor’s output characteristics, influencing speed and torque for different operational needs.

Types of Hydraulic Motors in Excavators

Excavators primarily utilize axial piston hydraulic motors due to their efficiency and power density. These motors are also common in other heavy equipment like skid steer loaders and tractors. A well-maintained excavator final drive, which includes the travel motor, typically lasts between 5,000 and 7,000 hours of operation. However, several factors can impact their longevity. Hydraulic system contamination, improper fluid management, and inadequate lubrication are common issues that can lead to reduced efficiency and premature wear. Consistent operation beyond specified load parameters also places excessive stress on internal components, causing accelerated wear.

The Final Drive Motor: Gear Reduction and Torque Multiplication

Defining the Final Drive's Function

The final drive motor acts as the crucial link between the travel motor's hydraulic power and the excavator's tracks. It does not generate power itself. Instead, it takes the rotational energy from the travel motor and converts it into the high torque necessary to move the heavy machine. This component significantly reduces speed while simultaneously multiplying torque, allowing the excavator to overcome resistance and navigate challenging terrain effectively.

How Final Drives Convert Power to Torque

Final drives convert power to torque primarily through a sophisticated gear reduction system. Most final drives utilize planetary gear systems. Here, a central sun gear receives the initial rotation from the hydraulic motor. This spinning sun gear then turns the surrounding planet gears. These planet gears, simultaneously meshing with a stationary outer ring gear, are forced to 'walk' or orbit around the inside of the ring gear. This orbital movement causes the planet gears' mounting bracket, known as the carrier, to rotate at a significantly slower speed. This reduction in speed directly results in a substantial increase in torque. The system effectively transforms fast, low-torque input into the slow, high-torque output required for heavy machinery movement.

Internal Components of a Final Drive

A final drive contains several key internal components working in unison. These include the sun gear, planet gears, ring gear, and the planet carrier, all housed within a robust casing. Bearings support the rotating shafts and gears, ensuring smooth operation and minimizing friction. Seals prevent lubricant leakage and keep contaminants out. The gear ratios within these systems are critical for performance. Typical final drive ratios for excavators generally fall within the range of 20:1 to 30:1. This ratio can vary based on the excavator's size and its intended operational use. For smaller excavators, such as mini excavators, the ratio might be slightly lower, as these machines prioritize maneuverability and efficiency over sheer power.

Distinguishing Functions: Travel Motor Powers, Final Drive Drives

Power Generation vs. Mechanical Advantage

The travel motor and final drive perform fundamentally different roles in an excavator's propulsion system. The travel motor acts as the power generator. It converts the hydraulic energy from the excavator's pump into rotational mechanical energy. This means the travel motor creates the initial turning force. In contrast, the final drive does not generate power. Instead, it provides mechanical advantage. It takes the rotational energy from the travel motor and transforms it. This transformation involves significantly reducing the rotational speed while simultaneously multiplying the torque.

Consider the dramatic difference in torque. A typical excavator's final drive motor can achieve a maximum output torque of 75,000 Nm. This comes from a maximum input torque of only 440 Nm from the hydraulic motor. This represents an impressive ratio of 166:1. This mechanical advantage allows the excavator to move its heavy tracks and overcome substantial resistance. The final drive effectively translates the travel motor's high-speed, low-torque output into the low-speed, high-torque required for heavy-duty movement.

Hydraulic Input to Mechanical Output

The entire process of moving an excavator's tracks involves a precise conversion chain from hydraulic input to mechanical output. High-pressure hydraulic fluid first enters the travel motor. The travel motor then converts this fluid pressure and flow into a rotating shaft. This shaft delivers mechanical power at a certain speed and torque. This initial mechanical output then feeds directly into the final drive.

The final drive takes this input and further modifies it. It uses its internal gear reduction system to dramatically increase the torque. For example, a hydraulic motor might produce 200 Nm of torque at 3,000 RPM. When this input goes through a final drive with a 20:1 reduction ratio and 95% mechanical efficiency, the output torque becomes 4,000 Nm. This output torque is then delivered to the sprocket, which engages the track chain. This entire sequence ensures the excavator receives the necessary force to propel itself. The relationship is clear: Output Torque = Input Torque × Gear Ratio × Mechanical Efficiency.

The Interdependent Relationship

The travel motor and final drive operate as an inseparable unit. Neither component can effectively perform its function without the other. The travel motor provides the essential rotational input. Without this input, the final drive has no power to multiply. Conversely, the final drive translates the travel motor's output into a usable form. The travel motor's direct output would be too fast and lack sufficient torque to move the heavy excavator tracks efficiently.

Together, they form a complete propulsion system. The travel motor initiates movement by converting hydraulic power. The final drive then optimizes this movement by providing the necessary torque and controlling the speed. This interdependent relationship ensures the excavator achieves both mobility and the power to navigate diverse terrains. They are two distinct parts working in perfect harmony to achieve a single goal: efficient track movement.

Integrating Components in Construction Equipment Hydraulic System OEM

Compatibility and Performance Requirements

Integrating components within a construction equipment hydraulic system OEM requires careful consideration of compatibility and performance. Manufacturers must ensure that all parts work together seamlessly. A replacement final drive must be compatible with the existing equipment. Some distributors might offer non-OEM parts or products that lack compatibility. For instance, a John Deere or Volvo component will not function with a Komatsu machine. To ensure the excavator track motor purchased is compatible, provide details like the machine's make, model, and serial number. Sales teams can then verify compatibility, ensuring the construction equipment hydraulic system OEM receives the correct part.

Selecting the Right Travel Motor Final Drive

Selecting the correct travel motor and final drive is crucial for any construction equipment hydraulic system OEM. It directly impacts machine performance. When choosing a final drive, identify the mini excavator's specifications. Knowing the exact model and manufacturer is essential. This information is typically found in the operator’s manual or on the machine’s identification plate. The final drive must match the excavator's weight class; a drive for a 3-ton machine will not work on a 5-ton machine. The track type, whether rubber or steel, can also influence the required final drive. Ensure the chosen final drive matches the specific excavator model's hydraulic flow rate and pressure. This prevents poor performance or damage to the construction equipment hydraulic system OEM.

Impact on Excavator Mobility

The selection of a travel motor and final drive significantly impacts an excavator's overall mobility and fuel efficiency. Hydraulic systems, including the final drive, optimize energy use by distributing power according to task demands. This leads to improved fuel efficiency for the construction equipment hydraulic system OEM. Electro-hydraulic controls can reduce energy consumption by decreasing engine RPMs during light work, potentially cutting energy needs by 5%. Technologies like Doosan's Smart Power Control (SPC) adjust the engine workload to match hydraulic pump output. This results in significant fuel savings, lower operating costs, and reduced emissions. Neglected tracks can lead to sluggish travel and higher fuel consumption. This directly impacts the efficiency of the final drive motor and the overall machine. The travel motor enhances power efficiency by regulating hydraulic pressure. This allows the excavator to deliver the necessary power for movement while conserving fuel, particularly on flat or low-resistance terrain.

Identifying Each Component on an Excavator

Understanding the physical appearance and placement of the travel motor and final drive helps with maintenance and troubleshooting. Operators can quickly identify these crucial parts.

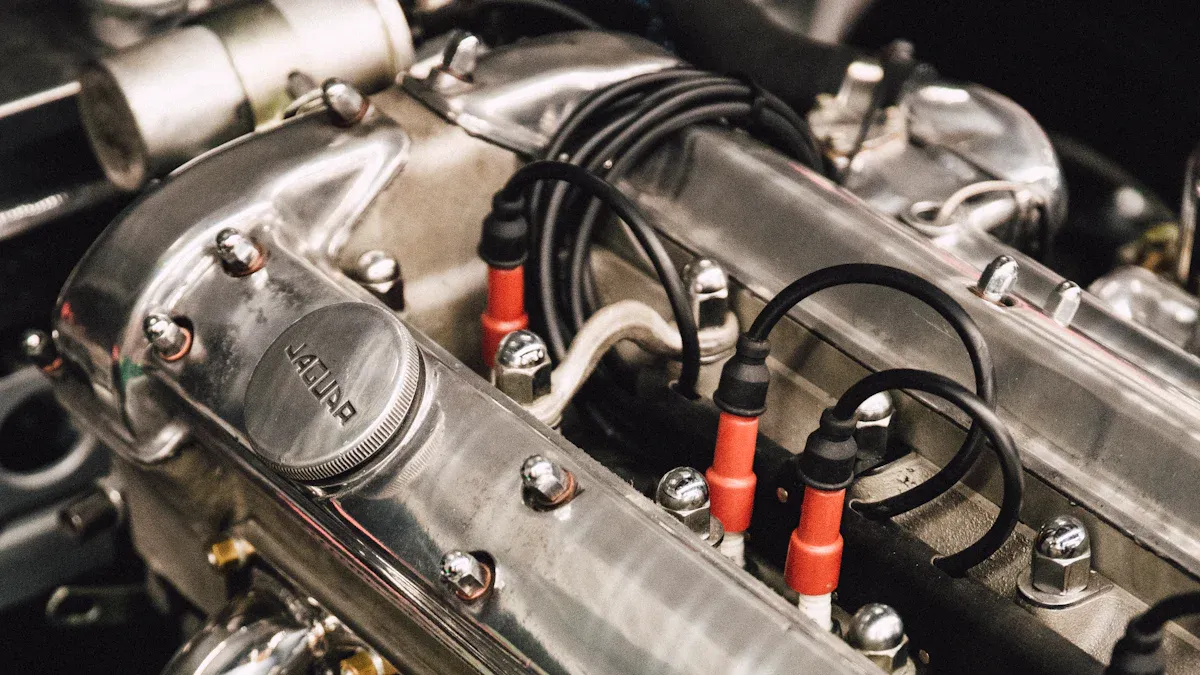

Visual Characteristics of Travel Motors

Travel motors typically appear as compact, cylindrical, or somewhat rectangular units. They often have multiple hydraulic lines connected to them. These lines supply the high-pressure fluid that powers the motor. You might also see a drain line. The travel motor usually has a smooth, metallic casing. It often looks like a smaller component attached to a larger assembly.

Visual Characteristics of Final Drive Motors

The final drive motor presents a much more robust and bulkier appearance. It features a large, often rounded or bell-shaped housing. This housing contains the complex planetary gear system. The final drive directly connects to the sprocket that drives the excavator's tracks. It has a sturdy, heavy-duty construction designed to withstand significant forces. You will notice a large output shaft extending from it, which engages the sprocket.

Location within the Undercarriage

Both components reside within the excavator's undercarriage. They are positioned at the rear of each track frame. The final drive motor is the outermost component. It directly bolts to the track frame and connects to the track sprocket. The travel motor typically mounts directly onto the final drive's input side. This integrated setup ensures a direct power transfer. Each track on the excavator has its own independent travel motor and final drive assembly. This allows for precise control and maneuverability.

The travel motor functions as the excavator's hydraulic power unit. The final drive serves as its mechanical gear system. Together, these components enable efficient track movement. Understanding their distinct roles is key for optimal excavator performance. Regular checks, including oil levels and seals, ensure their longevity and reliability.

FAQ

What is the primary function of a travel motor?

A travel motor converts hydraulic fluid pressure into rotational mechanical energy. This energy drives the excavator's tracks, enabling movement.

What role does the final drive play in an excavator?

The final drive multiplies torque and reduces speed from the travel motor. It provides the necessary force to move the heavy excavator tracks.

Why is compatibility important when replacing a final drive?

Compatibility ensures proper function and prevents damage. A final drive must match the excavator's make, model, and specifications for optimal performance.

Post time: Jan-26-2026