Choosing the right hydraulic motor for an excavator production line is crucial. Define its specific tasks, like track drive or attachment operation. Determine maximum torque, speed, and power demands. Assess the operating environment, including temperature and dust. Consider peak performance duration. A reliable excavator hydraulic motor supplier provides essential guidance. A leading hydraulic travel motor manufacturer China offers suitable options.

Key Takeaways

- Understand what the motor needs to do, like moving tracks or operating tools, and how much power it needs.

- Consider where the excavator will work, such as hot or dusty places, and how often the motor will run at full power.

- Choose the right type of motor, like a piston motor for heavy work, and pick a supplier who offers good support after you buy it.

Essential Considerations for Your Excavator's Hydraulic Motor

Defining Application Needs and Load Characteristics

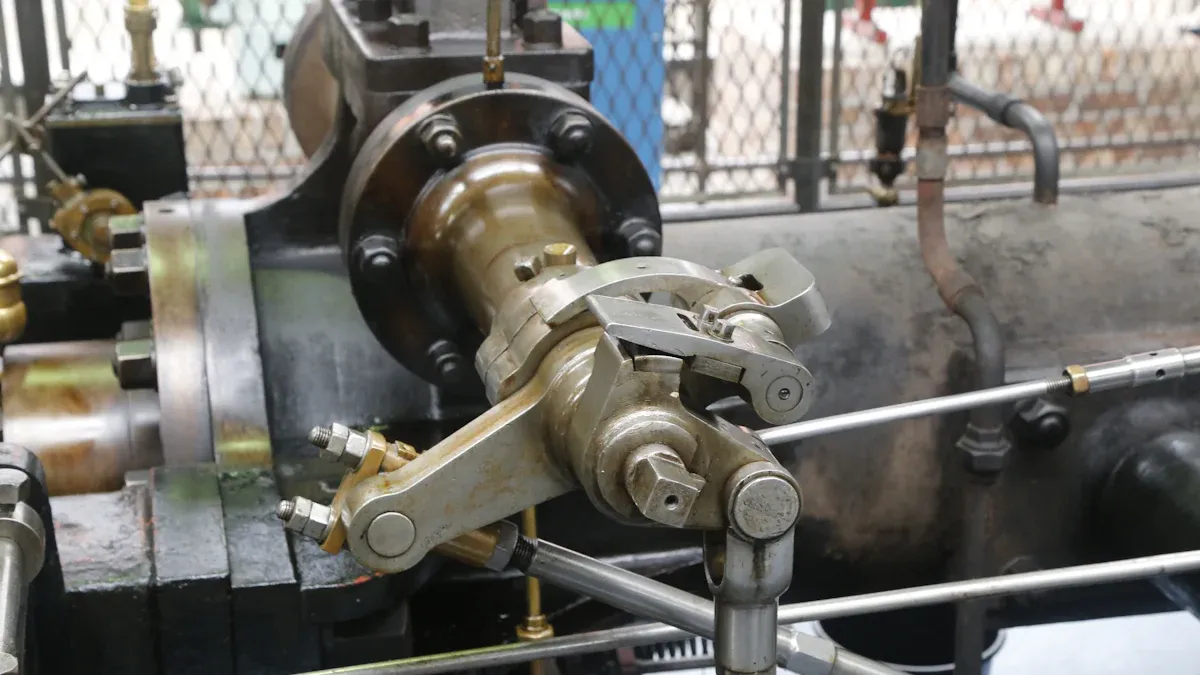

Selecting the correct hydraulic motor begins with a clear understanding of its intended role. Engineers must precisely define the specific tasks the motor will perform within the excavator's production line. These tasks include track drive, swing mechanisms, or various attachment operations. Each function demands different performance characteristics from the motor. For instance, a track drive motor requires significant torque to propel the heavy machinery. A standard 1.8-ton mini excavator, for example, requires a drive motor with a maximum output torque reaching 2500 Nm. This torque provides sufficient power for navigating challenging terrains such as mud, sand, and slopes. Furthermore, engineers must determine the maximum torque, speed, and power demands for each specific application. This detailed analysis ensures the chosen motor can handle the operational stresses without compromising performance or longevity.

Assessing Operating Environment and Duty Cycle

The operating environment significantly influences hydraulic motor selection. Engineers must consider factors such as temperature, dust, vibration, and potential contaminants. Extreme temperatures, both hot and cold, affect hydraulic fluid viscosity and motor efficiency. It is advisable to avoid hydraulic fluid temperatures exceeding 180°F (82°C). Temperatures above this point can damage most seal compounds and accelerate the degradation of the hydraulic oil. Furthermore, fluid temperature becomes too high when its viscosity drops below the optimal level required for the system's components, which can occur even below 180°F depending on the fluid's viscosity grade. Dust and contaminants can lead to premature wear if the motor lacks adequate sealing and filtration. Vibration can stress components, while corrosive elements demand specialized materials. The duty cycle also plays a critical role. Engineers must assess how frequently and for how long the motor will operate at peak performance. A motor constantly running at its maximum capacity requires different specifications than one used intermittently.

Understanding Key Motor Specifications

A thorough understanding of key motor specifications is paramount for optimal selection. These specifications include displacement, pressure ratings, speed ranges, torque output, and efficiency. Each parameter directly impacts the motor's performance and suitability for a given application. Engineers must interpret these figures in the context of the excavator's overall hydraulic system. This comprehensive approach ensures the motor integrates seamlessly and performs reliably.

Matching Displacement, Pressure, and Speed

Matching displacement, pressure, and speed is fundamental to hydraulic motor selection. Hydraulic pumps generate flow by creating pressure against the resistance of hydraulic fluids, enabling various functions. Relief valves are essential for maintaining system integrity by releasing excess pressure, preventing damage to components, and ensuring the system operates within safe limits. The pressure-flow curve illustrates the relationship between hydraulic pressure applied to the motor and the flow rate of the hydraulic fluid. As pressure increases, the flow rate may decrease due to the motor's internal resistance. Understanding this curve is crucial for sizing hydraulic system components to meet the motor's requirements, especially under varying loads. Excessive backpressure reduces efficiency, forcing the hydraulic pump to work harder to maintain the desired flow rate, leading to increased energy consumption and higher operational costs. It also accelerates wear and tear on hydraulic components like pumps and motors due to increased stress, potentially leading to premature failure of seals, hoses, and fittings. In extreme cases, excessive backpressure can cause catastrophic system failure, including ruptures or leaks, resulting in fluid loss, operational downtime, and safety risks.

Evaluating Torque Output and Efficiency

Evaluating torque output and efficiency is critical for an excavator's performance. Torque and power are closely linked in hydraulic motors, with power calculated as the product of torque and rotational speed. Hydraulic motors are ideal for applications requiring significant force due to their ability to deliver high torque at low speeds, enabling them to handle heavy loads efficiently. Excavators utilize hydraulic motors to power their tracks, facilitating precise control and powerful digging. The operating weight of an excavator is a crucial parameter that determines its level and sets the upper limit for its digging force. If the digging force surpasses this limit, the excavator can slip; for a backhoe, it will be pulled forward, and for a forward shovel, it will slip backward, posing safety risks.

Hydraulic motors convert pressurized fluid into rotation, while reduction gears adjust speed and boost torque output. For instance, a motor running at 500 RPM paired with a 20:1 reduction ratio results in a final drive of 25 RPM, but the torque is multiplied by twenty times. This combination allows excavators to generate between 8,000 and 12,000 Newton meters of torque, essential for digging through tough soil. Reduction gears transform high-speed, low-torque input into low-speed, high-torque output, enabling powerful lifting and controlled movement. The relationship is defined by: Output Torque = Input Torque × Gear Ratio × Mechanical Efficiency. A hydraulic motor producing 200 Nm at 3,000 RPM, when paired with a 20:1 reduction, yields 4,000 Nm output torque (at 95% efficiency) and 150 RPM output speed. This configuration allows an 18-ton excavator to generate 25 kN·m of bucket force.

| Reduction Ratio | Torque Impact | Speed Impact | Application |

|---|---|---|---|

| 30:1 system | 15% more torque than 25:1 | Reduces speed by 20% | Mining excavators (prioritizing maximum torque) |

| 25:1 system | - | - | - |

| 30–40:1 | Maximum torque | - | Mining excavators |

| 18–25:1 | - | - | Compact models (emphasizing mobility) |

Ensuring Mounting Configuration Compatibility

Ensuring mounting configuration compatibility is a practical, yet vital, step in motor selection. Engineers must verify that the chosen hydraulic motor physically fits into the available space on the excavator. This includes checking the shaft type, flange type, and port locations. Incompatibility can lead to costly modifications or delays in the production line. Consulting an experienced excavator hydraulic motor supplier can provide valuable insights and ensure proper fitment. They often offer a range of mounting options to suit various excavator designs.

Selecting the Right Hydraulic Motor Type and an Excavator Hydraulic Motor Supplier

Suitability of Gear, Vane, and Piston Motors

Choosing the correct hydraulic motor type is a pivotal decision for an excavator production line. Each motor type—gear, vane, and piston—offers distinct characteristics suitable for different applications. Piston motors are widely utilized in heavy equipment requiring high torque, such as excavators, due to their high efficiency and durability. They deliver high torque at low speeds, possess high power density, and offer a wide speed and torque range. This makes them ideal for heavy lifting and digging tasks. However, piston motors come with a higher initial cost, a more complex design, and greater sensitivity to contamination.

| Feature | Piston Motors | Gear Motors |

|---|---|---|

| Advantages | High efficiency, high torque at low speeds, high power density, wide speed/torque range | Low cost, simple design, reliable operation, suitable for moderate-duty applications |

| Disadvantages | Higher initial cost, complex design, sensitive to contamination | Lower efficiency, limited torque/speed capabilities, larger size/heavier weight |

| Excavator Application | Used in excavators for high torque at low speeds for heavy lifting and digging | Not explicitly stated as suitable for heavy-duty excavator operations due to limitations |

In contrast, gear motors feature a simple structure and lower cost. They are more appropriate for medium and light load applications. Their disadvantages include lower efficiency, limited torque and speed capabilities, and a larger size and heavier weight compared to piston motors for similar power output. Vane motors find common use in various excavator functions. These include powering hydraulic cylinders for boom and arm extension/retraction, bucket operation, and the swing mechanism. They also drive hydraulic motors for track drive and rotators for attachments like breakers or grapples. Vane motors are also suitable for excavator attachments, skid steer hydraulics, road-pavers, and winches.

Advantages of Gerotor/Geroller Motors for Specific Applications

Gerotor and Geroller motors offer specific advantages, particularly for excavator swing or travel drives. These motors are classified as LSHT (low-speed high-torque) hydraulic motors. They generate significant torque for traction-intensive applications common in construction. Geroler motors, a variation of Gerotor motors, incorporate rolls in the outer rotor. These rolls act as bearings. This design reduces friction, decreases wear, increases efficiency, and provides smoother operation. Geroler motors outperform standard Gerotor motors in these aspects.

Gerotor hydraulic motors are an ideal solution for applications requiring considerable torque in challenging environments. Brands like Eaton/Char-Lynn and Danfoss frequently feature Gerotor motors in construction equipment. They are well-suited for delivering torque in rugged conditions. These motors are compact, reversible, and affordably priced. They excel in low-speed, high-torque (LSHT) applications. They are highly effective when high starting torque and robustness under heavy loads are required. Orbital/Gerotor/Geroller motors, a subset of gear-type motors, utilize an inner and outer rotor design. They are employed in specialized, compact applications. Construction machinery uses them for excavator swing drives, wheel drives, and crane mechanisms.

Impact of System Pressure, Flow, and Contamination Tolerance

The hydraulic system's pressure, flow, and contamination tolerance significantly impact motor selection. Excavators operate under high pressures, demanding motors capable of handling these forces without failure. The flow rate dictates the motor's speed. A motor must match the system's flow capacity to achieve desired operational speeds. Contamination tolerance is also critical. Hydraulic systems in construction environments are prone to dust and debris. Motors with robust sealing and materials resistant to abrasive particles ensure longevity and reliable performance. An experienced excavator hydraulic motor supplier can guide you in selecting motors designed for these demanding conditions.

Considering Noise Levels, Size, and Weight Constraints

Practical considerations like noise levels, size, and weight constraints also play a crucial role. Noise emissions from hydraulic motors can impact operator comfort and compliance with environmental regulations. Several international standards address noise levels for hydraulic motors and construction equipment. ISO 4412-2:1991 provides a test code for determining airborne noise levels specifically for hydraulic motors. ISO 4871:1996 covers the declaration and verification of noise emission values for machinery and equipment. ISO 11200:2014 and ISO 11201:2010 offer guidelines for determining emission sound pressure levels at a workstation. The physical size and weight of the motor must fit within the excavator's design envelope. A compact and lightweight motor can improve the excavator's overall balance and maneuverability.

Performing a Comprehensive Cost-Benefit Analysis

A comprehensive cost-benefit analysis is essential before finalizing a motor choice. This analysis goes beyond the initial purchase price. It includes evaluating long-term operational costs, such as energy consumption and maintenance requirements. Consider the motor's efficiency, as a more efficient motor reduces fuel consumption over its lifespan. Assess the availability and cost of spare parts. Also, consider the expected lifespan of the motor and its warranty. Partnering with a reputable excavator hydraulic motor supplier like INI Hydraulic, known for designing and manufacturing hydraulic motors for over 26 years, ensures access to quality products and reliable after-sales support. This strategic approach helps optimize the total cost of ownership and ensures the chosen motor delivers maximum value.

Practical Steps for Motor Selection and Integration

Consulting Manufacturer Specifications and Data Sheets

Manufacturers' specifications and data sheets offer crucial details. Engineers must verify several critical aspects. These include the motor's noise output and its tolerance for pressure, speed, and temperature variations. They also check the control method, considering power consumption and automation needs. Maintenance requirements, including frequency and complexity, are important for sustaining the motor's lifespan. The bearing type and its expected operational life are crucial for planning. Engineers determine if the motor suits a closed-loop or open-loop hydraulic system. They assess the motor's susceptibility to contaminants and its necessary approvals and certifications.

Seeking Expert Advice from Hydraulic Specialists

Seeking expert advice from hydraulic specialists provides invaluable guidance. These professionals offer insights into complex hydraulic systems and motor compatibility. They help engineers navigate technical challenges and optimize motor selection for specific excavator production line needs. Their expertise ensures efficient integration and long-term performance.

Planning for Future Expansion and Upgrades

Planning for future expansion and upgrades is a forward-thinking approach. Modern excavators increasingly integrate advanced hydraulic systems, enabling superior power and precision. IoT-enabled sensors and artificial intelligence are becoming common for real-time data analytics and predictive maintenance. Smart hydraulics represent a key technological trend, with a projected market share increase to 35% by 2025. Electro-hydraulics with Independent Metering Valve Technology (IMVT) also offer significant advancements. IMVT combines intelligent electronic control, independent cylinder control, and customizable functions, setting new standards for efficiency and versatility.

Evaluating After-Sales Support and Parts Availability

Evaluating after-sales support and parts availability is essential for operational continuity. A reputable excavator hydraulic motor supplier provides comprehensive warranty terms, reflecting confidence in product quality. Robust after-sales support includes technical consultations, troubleshooting guidance, and maintenance services. Timely support from knowledgeable professionals minimizes equipment downtime. Value-added benefits like training and preventive maintenance recommendations are also important. Transparency in warranty and service procedures is crucial. While common maintenance items like filters ship within days, specialized hydraulic components can have lead times ranging from 2-4 weeks from US warehouses or 6-12 weeks from overseas.

Making an informed decision on hydraulic motor selection is crucial for excavator production line performance. Balancing specific requirements with motor specifications optimizes operations. An unsuitable motor can lead to significant financial losses, with emergency repairs costing $85,000-$145,000 per incident. Strategic motor choice enhances efficiency, reliability, and profitability, preventing issues like overheating and weakening travel motors.

FAQ

What is the most important factor when choosing an excavator hydraulic motor?

Defining the motor's specific application needs and load characteristics is paramount. This ensures the motor meets the excavator's operational demands effectively.

Which hydraulic motor type is best for heavy-duty excavator tasks?

Piston motors are ideal for heavy-duty excavator tasks. They offer high efficiency, significant torque at low speeds, and excellent power density for demanding work.

How does a good supplier help with motor selection?

A good supplier, like INI Hydraulic, provides expert advice, ensures product quality, and offers reliable after-sales support. This optimizes motor integration and performance.

Post time: Jan-08-2026