Global OEMs increasingly rely on Chinese hydraulic motor manufacturers. This trust stems from a proven track record of meeting stringent global demands. Manufacturers consistently deliver high-quality components for a construction equipment hydraulic system OEM. They also provide specialized parts, such as a robust planetary gearbox for excavator applications. This demonstrates their commitment to performance and reliability.

Key Takeaways

- Chinese hydraulic motor makers use new technology. They make motors that work well and last a long time. This helps global companies trust them.

- Chinese manufacturers offer good prices. They have many different motor types. They can also make custom parts for specific needs.

- Chinese companies quickly meet market needs. They give good technical help. They also build strong partnerships with global customers.

Advanced Technology, Performance, and Reliability for Global OEMs

Innovation in Hydraulic Motor Design and Performance

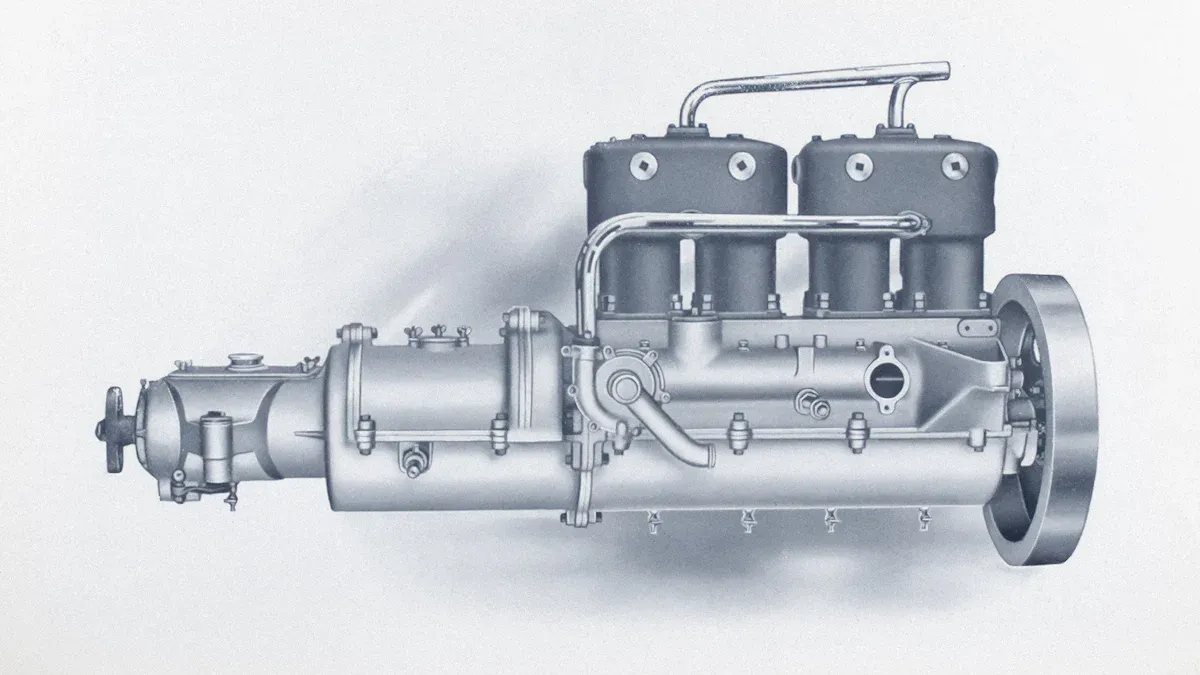

Chinese hydraulic motor manufacturers consistently push the boundaries of design and performance. They invest heavily in research and development. This commitment leads to significant technological advancements. For example,Ini Hydraulic Co., Ltd. creates high-efficiency designs. These designs convert hydraulic energy to mechanical energy with greater power output and less energy consumption. Shanghai Electric Hydraulic focuses on compact structures and high torque output. Their designs suit heavy-duty applications and operate with low noise. Yantai Hydraulic Components uses energy-saving designs. These designs reduce consumption while maintaining high performance.

Other manufacturers also contribute to this innovation. Jiangsu Hengli Hydraulic incorporates advanced materials for enhanced durability. They also integrate intelligent control technology. This technology uses sensors and control systems for real-time monitoring and adjustment. Shandong Yantai Hydraulic Technology offers high-speed performance. Their motors are suitable for fast-moving equipment. They also feature high-pressure resistance and low-vibration designs. Zhejiang Donghua Hydraulic develops compact and lightweight motors. These motors fit well in space-limited applications. They also ensure smooth operation through precise machining. Liaoning Hydraulic provides cold-resistance performance for low-temperature environments. Sichuan Hydraulic Equipment focuses on adaptability for mountainous terrain. These innovations directly benefit a global construction equipment hydraulic system OEM.

Manufacturing Excellence and Quality Control

Chinese manufacturers prioritize manufacturing excellence and strict quality control. They adopt advanced processes and adhere to high standards. Many companies use self-designed intelligent flexible processing production lines. These lines significantly improve product performance and quality. Some products even follow military design standards. These standards are 2-3 levels higher than normal design standards. This shows a strong commitment to superior quality.

Manufacturers use flexible production lines with automation. Robotic arms handle materials. Technicians transmit data for automatic, customized production. They also engage in continuous technological transformation. This involves updating production equipment to enhance efficiency. Many manufacturers hold international certifications. For instance, China Shijiazhuang Hanjiu Technology Co., Ltd. holds CE certifications. Other companies achieve ISO9001 and CE certifications. These certifications demonstrate compliance with global quality standards. Intelligent production lines use world-class equipment. This equipment allows for high processing precision. CNC hobbing machines and gear milling machines control meshing clearance within 0.01 mm. This ensures millimeter-level accuracy.

Reliability and Durability in Operation

The reliability and durability of Chinese hydraulic motors are key reasons for OEM trust. Manufacturers use high-quality materials and advanced manufacturing processes. This ensures long-lasting performance. Motors are designed to withstand demanding operational conditions. They perform reliably in various environments, from extreme cold to rugged terrain. The focus on precision engineering and robust construction leads to fewer breakdowns. This reduces maintenance needs for end-users. The continuous improvement in design and manufacturing processes directly translates into dependable products. These products meet the rigorous demands of global industries.

Cost-Effectiveness and Strategic Value for Construction Equipment Hydraulic System OEM

Competitive Pricing and Optimized Production

Chinese hydraulic motor manufacturers offer highly competitive pricing. They achieve this through lower labor and material costs. This allows them to provide affordable motors without sacrificing performance. Small and mid-sized businesses globally can access hydraulics more easily. Manufacturers optimize production through advanced technologies and economies of scale. This leads to competitive pricing. In 2022, China held over 30% of the global hydraulic pump market. This shows their significant production capabilities. Substantial investments in automation and supply chain optimization support this growth. The hydraulic equipment market will likely reach USD 50 billion by 2025. Chinese manufacturers expect to maintain a strong competitive edge. Their robust performance and budget-friendly pricing contribute to this.

Chinese manufacturers use innovative technologies. These include smart automation, IoT, and AI. They redefine manufacturing standards with these tools. These technologies increase precision and efficiency in production. They also allow real-time performance monitoring. This enhances reliability and reduces downtime. This technological integration significantly lowers operational costs. It contributes to competitive pricing. Manufacturers also adopt sustainable practices. These include green technologies and renewable energy sources. This enhances production efficiency and reduces costs. They implement advanced recycling processes. This reuses materials, minimizes waste, and conserves resources. This further contributes to cost-effective production. Rigorous quality control measures are crucial for optimizing production. These include comprehensive quality management systems and advanced inspection technologies. These systems ensure each motor meets strict international standards. They monitor production meticulously from design to testing. Automated inspection systems and data analytics enable real-time adjustments. They enhance production consistency and significantly reduce defects. This leads to superior product reliability and overall efficiency.

Diverse Product Offerings and Customization

Chinese manufacturers provide a wide range of hydraulic motor types. They meet diverse application needs for a construction equipment hydraulic system OEM. They offer gear motors. These are compact, lightweight, and easy to maintain. They have good oil suction capacity and impact resistance. Gear motors typically have low starting torque and relatively low volumetric efficiency. They suit high-speed, low-torque applications. Orbit motors, also known as gerotor or geroler motors, produce large torques at very slow speeds. Construction vehicles like skid steers, bulldozers, and excavators use them. They also power sweeper brushes and backhoe bucket/arm actuation. Vane motors feature a simple design and small size. They offer high torque at low speeds, stable operation, and low noise. They are particularly suited for vertical installations.

Piston motors come in two types. Radial piston motors offer low speed and high torque. They generate higher torque than axial piston motors. Axial piston motors generate lower torque but have a higher speed range. For example, hydraulic gear motors are simple, durable, and low-cost. They offer high efficiency in low-speed applications and stable output torque. Agricultural machinery and construction equipment commonly use them. Hydraulic vane motors have a simple structure. They handle moderate loads and medium pressure. They also offer a wide speed regulation range. Hydraulic orbit motors provide high efficiency and low pulsation noise. They offer high durability and suit stable torque output. They adapt to different flow and torque requirements. Hydraulic piston motors generate torque through multiple pistons. Axial piston hydraulic motors offer high efficiency and stable torque output. They suit high-load and high-pressure environments. Excavators and bulldozers use them. Radial piston hydraulic motors provide high torque output. They are especially useful for high starting torque applications. Wind turbines use them.

Chinese manufacturers also offer extensive customization capabilities. They meet specific OEM requirements. They customize port size, color, and single package size. They also adjust single gross weight, oil voltage, and transport package. Working pressure is adjustable from 6-35MPa and can be held. They use steel or stainless steel materials. Cylinder bore and stroke are customizable per client's request. Voltage and flow (400-6000rpm) are also adjustable. Manufacturers offer OEM, ODM, and customized orders for hydraulic power packs. They can also make non-standard or customized air cylinders. They design products according to customer needs. This flexibility makes them valuable partners for any construction equipment hydraulic system OEM.

Favorable Supply Chain Dynamics

Chinese manufacturers benefit from efficient supply chain dynamics. This includes competitive lead times and robust logistics. Standard hydraulic motor models typically ship within 15–25 days. Custom designs, which may require new tooling or performance tuning, generally take 30–45 days. Expedited production is available for urgent orders. This reduces lead times to 10–14 days, often with a 15–20% premium. Air freight for samples typically takes 5–10 days. Sea freight generally takes 20–35 days. Average ocean freight transit times to European and North American destinations are under 12 days. Proximity to major ports like Ningbo-Zhoushan and Shanghai Yangshan facilitates this. Air cargo options can further reduce delivery windows to 5–10 days for urgent orders.

The development of China's logistics infrastructure has significantly improved supply chain efficiency. This includes efficient ports, railways, and highways. Chinese wholesalers use these networks to streamline order fulfillment. They reduce lead times and offer consolidated shipping. This lowers freight costs. This robust infrastructure, combined with advanced inventory management, enables faster delivery. Strategic partnerships with freight forwarders minimize downtime. Improved logistics also facilitate smoother export processes. This includes handling necessary paperwork and customs clearance. This contributes to overall supply chain resilience and cost-effectiveness.

Market Responsiveness and Customer-Centric Service

Agile Response to Market Demands

Chinese hydraulic motor manufacturers show great agility in responding to market demands. They quickly adapt to evolving industry needs. This flexibility allows them to meet specific requirements from global OEMs. Manufacturers often adjust production lines rapidly. They also retool for new product specifications. This ensures a quick turnaround for new designs or increased volumes. Their ability to pivot quickly makes them valuable partners. They help a construction equipment hydraulic system OEM stay competitive.

Dedicated Technical Support and After-Sales Service

Manufacturers provide dedicated technical support and comprehensive after-sales service. They offer strong technical assistance for any product questions or issues. Their after-sales support includes replacing defective products with new ones. Many companies offer manufacturing, OEM, and customized services.

- They provide customization services, including ODM and OEM solutions.

- A 1-year warranty covers product maintenance.

- After-sales service includes late maintenance replacement and solutions for problems during use.

- They support product development cases and annually develop new products to improve functions.

Strong Partnership and Collaboration Models

Chinese manufacturers build strong partnerships and collaboration models with global OEMs. WEITAI Hydraulic aims to enhance high-end hydraulic system integration for international OEMs. This mission advances hydraulic technology innovation. It also leads the global expansion of Chinese hydraulic products. This shows a strategic focus on collaboration. Poocca Hydraulic Manufacturers provide ODM and OEM hydraulic solutions. They tailor hydraulic system products to each customer's needs. The company integrates R&D, design, production, sales, and maintenance within its operations. This comprehensive approach fosters deep, long-term relationships.

Chinese hydraulic motor manufacturers earned global OEM trust. They continuously improve and offer strategic advantages. Their ability to deliver on:

- Technology

- Cost

- Quality

- Service

These factors make them indispensable partners. The future of hydraulic motor manufacturing will see continued collaboration and innovation from these key players.

FAQ

What makes global OEMs choose Chinese hydraulic motors?

Global OEMs choose Chinese hydraulic motors for their advanced technology, reliable performance, and cost-effectiveness. Manufacturers offer diverse products and strong customer support.

How do Chinese manufacturers ensure product quality?

Chinese manufacturers ensure quality through strict control processes. They use advanced production lines and hold international certifications like ISO9001 and CE. Many products meet military design standards.

Do Chinese manufacturers offer customized solutions?

Yes, Chinese manufacturers offer extensive customization. They tailor products like port size, voltage, and materials to meet specific OEM requirements. This flexibility supports unique equipment designs.

Post time: Jan-16-2026