Igiya le-spur linamazinyo aqondile futhi lizungeza ku-eksisi ehambisanayo. Igiya lephini, ngokuvamile igiya elincane kupheya, lixhunywa negiya le-spur ukuze lidlulise ukunyakaza. Ngokuhlangene, amagiya e-spur ne-pinion adlulisa kahle amandla ezimbonini eziningi, okuhlanganisa izinhlelo zokusebenza zezimoto, i-aerospace, ne-Hydraulic Slewing.

Okuthathwayo Okubalulekile

- Amagiya e-Spur ne-pinion asebenzisana ukuze adlulise amandla ngendlela efanele phakathi kwama-parallel shafts, iphinikhodi ngokuvamile kube igiya lokushayela elincane.

- Lawa magiya ahlinzeka kakhuluukusebenza kahle okuphezulu, ngokuvamile ngaphezu kwama-98%, okuyenza ilungele imishini edinga ukulawula ukunyakaza okuthembekile nokunembayo.

- Amagiya e-Spur ne-pinion asetshenziswa kakhulu ezimbonini eziningi, okuhlanganisa ezezimoto, i-aerospace, kanyei-hydraulic slawing, ngenxa yokuqina kwazo kanye nokugcinwa kalula.

Indlela I-Spur ne-Pinion Gears Esebenza Ngayo

I-Basic Mechanics

Amagiya e-Spur ne-pinion asebenza ngezimiso zemishini ezilula kodwa ezinembile. Lawa magiya adlulisa ukunyakaza okujikelezayo phakathi kwamashafti ahambisanayo, agcina isilinganiso sesivinini esingashintshi. Iphrofayili yezinyo le-involute, umumo ogobile, iqinisekisa ukuhlangana okubushelelezi kanye nesivinini esiqinile phakathi nokusebenza.

- Iiphimbo indilingaiyindilinga ecatshangelwayo edlula endaweni lapho amazinyo amagiya amabili ehlanganyela khona. Leli phuzu elibizwa ngokuthi i-pitch point, yilapho amagiya edlulisa khona kahle kakhulu.

- Isenzo se-conjugate sisho ukuthi njengoba izinyo legiya elilodwa liphusha elinye, izinyo elishayelwayo lihamba ngesilinganiso esifanele, ligcina isilinganiso sejubane silungisiwe.

- Isilinganiso segiya sincike enanini lamazinyo noma ububanzi beziyingi zephimbo. Igiya elikhulu elibhangqwe nephinikhodi elincane liyanyusa i-torque kodwa lehlisa isivinini.

- Amagama abalulekile afaka:

- Imojuli(imethrikhi yosayizi wezinyo)

- I-diametral pitch(isilinganiso sombuso)

- I-engeli yokucindezela(ngokuvamile ngu-20°)

- Isilinganiso soxhumana naye(isilinganiso senani lamazinyo axhumene)

Qaphela:Isilinganiso sokuxhumana sisiza ukwabelana ngomthwalo phakathi kwamazinyo, okwenza isistimu yegiya ibe namandla futhi ibe bushelelezi.

Ukukhethwa kwezinto kudlala indima ebalulekile ekusebenzeni kwegiya. Insimbi, ithusi, kanye ne-thermoplastics njengenayiloni noma i-acetal yizinketho ezivamile. Insimbi inikeza amandla nokuqina, kuyilapho amapulasitiki ehlisa umsindo futhi amelana nokugqwala. Ithusi nensimbi engagqwali kusebenza kahle ezindaweni ezimanzi noma ezinokhahlo. Onjiniyela bavame ukusebenzisaUkwelashwa kokushisa okufana ne-carburizing noma ukuqina kwe-inductionukwandisa ubulukhuni bobuso nokwelula impilo yegiya.

Isethi yegiya elijwayelekile le-spur ne-pinion isebenzisa iphinikhodi njengegiya lokushayela. Amazinyo ayo ahlangene nalawo e-spur gear,ukunyakaza kokudlulisa kanye ne-torque. Amazinyo aqondile amagiya e-spur avumela ukudluliswa kwamandla okusebenzayo phakathi kwama-parallel shafts.

Ukunyakaza kanye Nokudluliswa kwamandla

Ukusebenzisana phakathi kwamazinyo egiya le-spur ne-pinion kunembe futhi kusebenza kahle. Amazinyo anezikhala ezindingilizini zawo zephimbo, lapho kudluliswa khona ukunyakaza okujikelezayo netorque. Njengoba iphini lizungeza, amazinyo alo adudulana emazinyweni egiya le-spur, okwenza i-spur gear iphenduke. Iphuzu lokuxhumana lihamba eduze kweumugqa wesenzo, umugqa ongokomfanekiso oqondisa ukudluliswa kwamandla phakathi kwamagiya.

- Amazinyo egiya abamba iqhaza kusiyingi se-pitch, ukunyakaza kokudlulisa kanye ne-torque.

- Iphuzu lokuxhumana lihamba ngomugqa wesenzo, liqinisekisa ukudluliswa kwamandla okushelelayo.

- Iphrofayili yezinyo ebandakanyayo inciphisa imithwalo yethonya futhi ivumele ukusebenzelana okuzinzile.

- Izici zejiyomethri ezifana nobubanzi bendilinga ye-pitch, i-engeli yokucindezela, kanye ne-backlash ithonya indlela i-mesh yamagiya eshelela ngayo.

- I-backlash, igebe elincane phakathi kwamazinyo, ivimbela ukugxuma futhi ivumela ukwanda kokushisa.

- I-engeli ye-meshing ithinta ukungqubuzana nomsindo ngesikhathi sokusebenza.

- Lezi zici zenza i-pinion ikwazi ukushayela igiya le-spur ngokusebenza kahle okuphezulu nokuthembeka.

Isilinganiso segiya, esichazwa njengenani lamazinyo egiyeni eliqhutshwayo elihlukaniswa ngenombolo egiyeni lokushayela, lithinta ngqo isivinini netorque. Ngokwesibonelo, a2:1 igiya isilinganisokusho ukuthi igiya elishayelwa lijika ngohhafu wejubane lephini kodwa lilethela kabili itorque. Lobu budlelwano buvumela onjiniyela ukuthi bakhe amasistimu amagiya afana nezidingo ezithile zokusebenza.

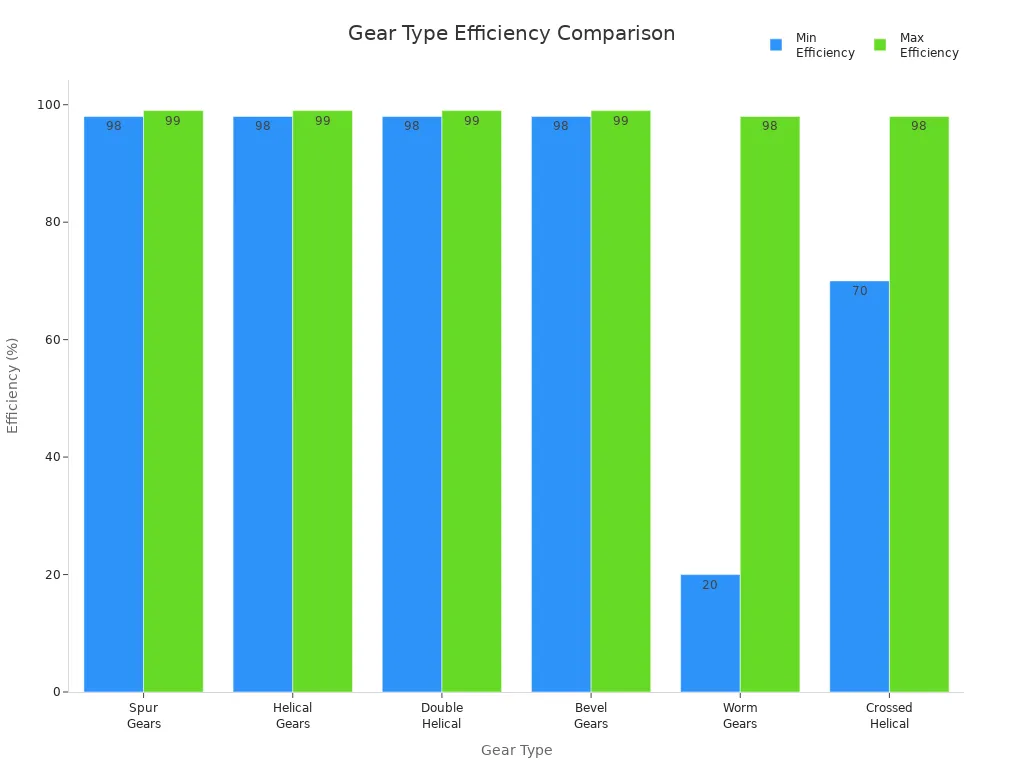

| Uhlobo Lwegiya | Ukusebenza kahle Range | Amaphuzu Abalulekile Ngempumelelo Nokulahlekelwa |

|---|---|---|

| Spur Gears | 98-99% | Ukusebenza kahle okuphezulu kakhulu; ukulahlekelwa okuncane ikakhulukazi okubangelwa ukungqubuzana kwamazinyo kanye nokugcotshwa kokugcoba |

| Amagiya e-Helical | 98-99% | Iphansi kancane kune-spur ngenxa ye-axial thrust kanye nesenzo sokuslayida |

| I-Double Helical | 98-99% | Iqhathaniswa namagiya e-spur kanye ne-helical |

| I-Bevel Gears | 98-99% | Ukusebenza kahle okuphezulu kodwa kuphansi kune-spur ngenxa yesenzo sokuslayida |

| Amagiya Worm | 20-98% | Ukusebenza kahle okuphansi kakhulu, kuncike kakhulu esilinganisweni segiya nezimo |

| I-Crossed Helical | 70-98% | Ukusebenza kahle okuphansi ngenxa yokushelela kanye nokuhlangana kwamazinyo okuyinkimbinkimbi |

Amagiya e-Spur nawe-pinion agqama ngokusebenza kwawo okuphezulu, ngokuvamile afinyelela ku-98-99%. Lokhu kuzenza zilungele izinhlelo zokusebenza lapho ukulahleka kwamandla okuncane kubalulekile. Kodwa-ke, amagiya e-spur ajwayelekhiqiza umsindo owengeziwe kunamagiya e-helicalngoba amazinyo abo ahlanganyela ngokuzumayo, akhiphe amandla kungazelelwe futhi abangele ukudlidliza. Amagiya e-Helical, anamazinyo ama-angle, asebenza ngokuthula kodwa ayinkimbinkimbi kakhulu ukuwenza.

Ukunakekela kubalulekile ekusebenzeni okuthembekile kwegiya. Izinkinga ezivamile zihlanganisaukuguga, ukungahambi kahle, kanye nokugcotshwa okwanele. Ukuhlola okuvamile kanye nokugcotshwa okufanele kusiza ukuvimbela izinkinga ezifana nokubhoboza, ukubola, nokuguga. Ukukhetha izinto ezifanele kanye nokugcina ukuqondanisa okulungile kwandisa isikhathi sokuphila samagiya e-spur ne-pinion, ukuqinisekisa ukudluliswa kwamandla okubushelelezi nangempumelelo emishinini eminingi.

Izici Eziyinhloko Nomehluko

I-Spur Gear Design

Amagiya akwaSpur agqama kakhulu kuwoamazinyo aqondile, ahamba ngokuhambisana ne-axis yegiya. Lo mklamo uvumela ukuthintana okuqondile phakathi kwezindawo zamazinyo, okuholela ekutheniukusebenza kahle okuphezulu-ngokuvamile ngaphezu kwama-98%. Amagiya e-Spur adlulisa ukunyakaza okujikelezayo phakathi kwama-parallel shafts futhi anomumo olula we-cylindrical. Amagiya amaningi e-spur angaphandle, anamazinyo onqenqemeni lwangaphandle, okwenza igiya elishayelwa lijike liye kolunye uhlangothi. Amagiya e-spur angaphakathi, anamazinyo ngaphakathi, avumela ukuvuleka kwe-shaft eseduze kanye ne-torque ephakeme kodwa adinga ukukhiqizwa okuyinkimbinkimbi.

| Isici | Spur Gears | Ezinye Izinhlobo Zegiya (Isifinyezo) |

|---|---|---|

| Izinyo Design | Amazinyo aqondile ahambisana ne-eksisi yegiya | I-Helical: amazinyo angama-angled; I-Bevel: i-conical; Isibungu: i-screw-like; Iplanethi: amagiya amaplanethi amaningi |

| I-Shaft Orientation | Ama-parallel shafts | I-Helical: ihambisana; I-Bevel: ihlangana; Isibungu: okungefani; Iplanethi: parallel/coaxial |

| Ukusebenza kahle | Phezulu (98% noma ngaphezulu) | I-Helical: kancane kancane; I-Bevel: emaphakathi; Isibungu: ngaphansi; Iplanethi: phezulu |

| Izinga Lomsindo | Kunomsindo ngesivinini esikhulu | I-Helical: ithule; I-Bevel: emaphakathi; Isibungu: thula; Iplanethi: emaphakathi |

| Inkimbinkimbi & Izindleko | Kulula, izindleko eziphansi | I-Helical: eyinkimbinkimbi kakhulu; I-Bevel: emaphakathi; Isibungu: inkimbinkimbi; Iplanethi: inkimbinkimbi kakhulu |

Inani lamazinyo egiyeni le-spur lithinta isilinganiso segiya, ukushelela, nokusabalalisa umthwalo. Onjiniyela bavame ukukhethaokungenani amazinyo ayi-18ukuze imiklamo ejwayelekile igweme ukusika phansi futhi uqinisekise ukusebenza okuthembekile.

Izimpawu Zegiya le-Pinion

Amagiya e-Pinion ngokuvamile ayigiya elincane ekubhanqweni. Ukuma kwabo esitimeleni segiya kunquma inzuzo yomshini wesistimu kanye nokuphuma kwamandla. Uma isetshenziswa kuma-rack-and-pinion systems, i-i-torque nesivinini se-pinion kuthonya ngokuqondile amandla nokunyakaza kwe-rack. Ezitimeleni zegiya leplanethi,ukukhweza okuguquguqukayo kwamagiya e-pinion kusiza ukusabalalisa imithwalo ngokulinganayo, ukuthuthukisa ukuqina nokunciphisa ukucindezeleka. Intuthuko ezintweni zokwakha, njengei-carbon fibre-reinforced polymers, akhulise ukuqina kwegiya lephini, okuwavumela ukuthi enze kahle ngisho nangaphansi kwezimo eziyinselele.

Ithiphu: Ukukhetha into efanele nokubalwa kwamazinyo kwegiya lephini kunganweba ubude bayo bempilo futhi kuthuthukise ukusebenza kwesistimu.

I-Spur Gear vs. Pinion Gear

Amagiya e-Spur namagiya e-pinion abelana ngezinqubo ezifanayo zokukhiqiza, zombili ziyazuzaukukhiqizwa okulula nokungabizi. Amagiya e-Spur asebenza njengomshayeli oyinhloko noma igiya elishayelwa, kuyilapho amagiya e-pinion evamise ukusebenza njengokufakiwe noma okokukhiphayo, ikakhulukazi kuma-rack-and-pinion noma amaplanethi. Amagiya e-Spur ngokuvamile aphatha ukudluliswa kwamandla ajikelezayo, kuyilapho amagiya e-pinion akwazi ukuguqula ukunyakaza okujikelezayo kube ukunyakaza komugqa. Zombili izinhlobo manje zisebenzisa izindlela ezisimeme zokukhiqiza, njengeukwakheka komumo oseduze nenethifuthiizinto ezigaywa kabusha, ukunciphisa umthelela kwezemvelo. Umehluko wabo ngosayizi, ukusebenza, kanye nokusebenza kwenza ngayinye ibaluleke ezinhlelweni zemishini.

Izicelo Ezisebenzayo kanye Ne-Hydraulic Slewing

Ukusetshenziswa Kwansuku zonke Nezibonelo

Amagiya e-Spur ne-pinion avela emikhiqizweni eminingi yansuku zonkekanye nemishini yezimboni. Lawa magiya abantu bawathola emshinini wokuthuthwa kwezimoto, esiteringini, ngisho nakumabhayisikili. Ezindlini, imishini yokuwasha, izixube, namawashi athembele kumagiya e-spur ukuze asebenze kahle. Amagiya e-pinion adlala indima ebalulekilei-rack kanye ne-pinion steering, ukusiza abashayeli ukulawula izimoto ngokunemba. Izimboni zisebenzisa la magiya kumabhande okuthutha, amaphampu, nemishini yokupakisha ukuze zihambise imikhiqizo kahle.

| Uhlobo Lwemboni / Lomshini | Izicelo Ezisebenzayo ze-Spur ne-Pinion Gears |

|---|---|

| Ezezimoto | Ukunciphisa amagiya, amasistimu okuqondisa, amarola omgwaqo |

| Imishini Yezimboni | Ama-gearbox, ama-conveyors, amaphampu, ama-compressor, amathuluzi omshini |

| I-Aerospace | Izilawuli zendiza, izinjini zendiza, izinto zokumisa |

| Ukukhiqiza Amandla | Ama-turbines omoya, iziteshi zikagesi ngamanzi |

| Imboni Yezindwangu | Imishini yokuphotha, yokuluka, yokudaya |

| Imikhiqizo Yabathengi | Amawashi, amaphrinta, amathuluzi kagesi |

| Imishini Yasekhaya | Imishini yokuwasha, blender, dryers |

| Amarobhothi kanye ne-Automation | Imishini ye-CNC, izindlela ze-servo |

| Izimoto Nezisetshenziswa Ezinejubane Eliphansi | Amabhayisikili, amahhanisi, izigayo zamabhola |

| Ama-Actuator Emishini | I-Rack kanye ne-pinion systems |

Amasistimu we-Hydraulic Slewingsebenzisa amagiya e-spur ne-pinion ukuzungezisa okokusebenza esindayo njengama-cranes nama-excavators. Lezi zinhlelo ziguqula amandla e-hydraulic motor abe ukunyakaza okulawulwayo, okwenza kube lula ukuphakamisa nokuphendula imithwalo emikhulu. Iumklamo ohlangene of Amadrayivu e-Hydraulic Slewingivumelaukufakwa kwe-plug-and-play, ukonga isikhathi phakathi nomhlangano.

Ukubaluleka Emishinini Nezisetshenziswa

Amagiya e-Spur nawe-pinion asekela imisebenzi eyinhloko yemishini eminingi. Banikeza ukusebenza kahle okuphezulu, ngokuvamile okufinyelelakufika ku-98%, okunciphisa ukulahlekelwa kwamandla futhi kugcina okokusebenza kusebenza kahle. Kuzinhlelo zokusebenza ze-Hydraulic Slewing, lawa magiya aqinisekisa ukuphenduka okunembile kanye ne-torque ezinzile, ngisho nangaphansi kwemithwalo esindayo. Izindlu ezivaliwe zama-Hydraulic Slewing drives zivikela amagiya othulini nasemanzini, okuwenza athembeke ezindaweni ezinokhahlo.

Abakhiqizi bakhetha amagiya e-spur ne-pinion ukuze aqine futhi agcinwe kalula. Amadrayivu e-Hydraulic Slewing ngokuvamile asebenzisa izinto eziqinile njengensimbi noma insimbi engagqwali ukuphatha imisebenzi enzima. Lawa madrayivu angasebenza ngenjini eyodwa noma amabili e-hydraulic, enikeza ukuguquguquka kwemishini ehlukene. Onjiniyela bayayazisa i-Hydraulic Slewing ngekhono layo lokuletha ukusheshisa kanye ne-torque ephezulu endaweni ehlangene.

Imakethe yomhlaba wonke yemishini esebenzisa amagiya e-spur ne-pinion inkulu. Ngo-2024,kwadayiswa amagiya e-spur angaphezu kwezigidi ezingu-15, nomkhakha wezimoto njengomsebenzisi omkhulu.Ubuchwepheshe beHydraulic Slewingiyaqhubeka nokukhula ngokubaluleka njengoba izimboni zidinga imishini esebenza kahle futhi enokwethenjelwa.

Amagiya e-Spur afaka amazinyo aqondilekanye nokudlulisa amandla phakathi kwama-parallel shafts.Iphini, njalo igiya elincane, amameshi anegiya le-spur ukulawula isivinini netorque.

- Amagiya e-Spur ne-pinion ayalethaukusebenza kahle okuphezulu, ukwethembeka, nokunembaemishinini efana nama-gearbox, amarobhothi, nezimoto.

- Onjiniyela balindele ukuqamba okusha okuqhubekayo ngeizinto ezingasindi kanye nokukhiqiza okuthuthukile, ukuqinisekisa ukuthi la magiya ahlala ebalulekile kubuchwepheshe besikhathi esizayo.

FAQ

Uyini umehluko omkhulu phakathi kwegiya le-spur negiya le-pinion?

Igiya le-spur lingaba yinoma yimuphi usayizi, kuyilapho igiya lephinikhodi lihlale liyigiya elincane kubhangqa. I-pinion ivamise ukushayela igiya le-spur.

Kungani onjiniyela bekhetha amagiya e-spur ne-pinion emishini?

Onjiniyela bakhetha amagiya e-spur ne-pinion ngokusebenza kahle kwawo okuphezulu, idizayini elula, nokudluliswa kwamandla okuthembekile. Lawa magiya asebenza kahle emishinini eminingi futhi adinga ukulungiswa okuncane.

Ingabe amagiya e-spur ne-pinion angakwazi ukuthwala imithwalo esindayo?

Yebo. Amagiya e-Spur ne-pinion, ikakhulukazi lawo enziwe ngezinto eziqinile njengensimbi, amakaniphatha imithwalo esindayoezintweni ezinjengama-cranes, ama-excavators, nama-gearbox wezimboni.

Isikhathi sokuthumela: Jul-25-2025