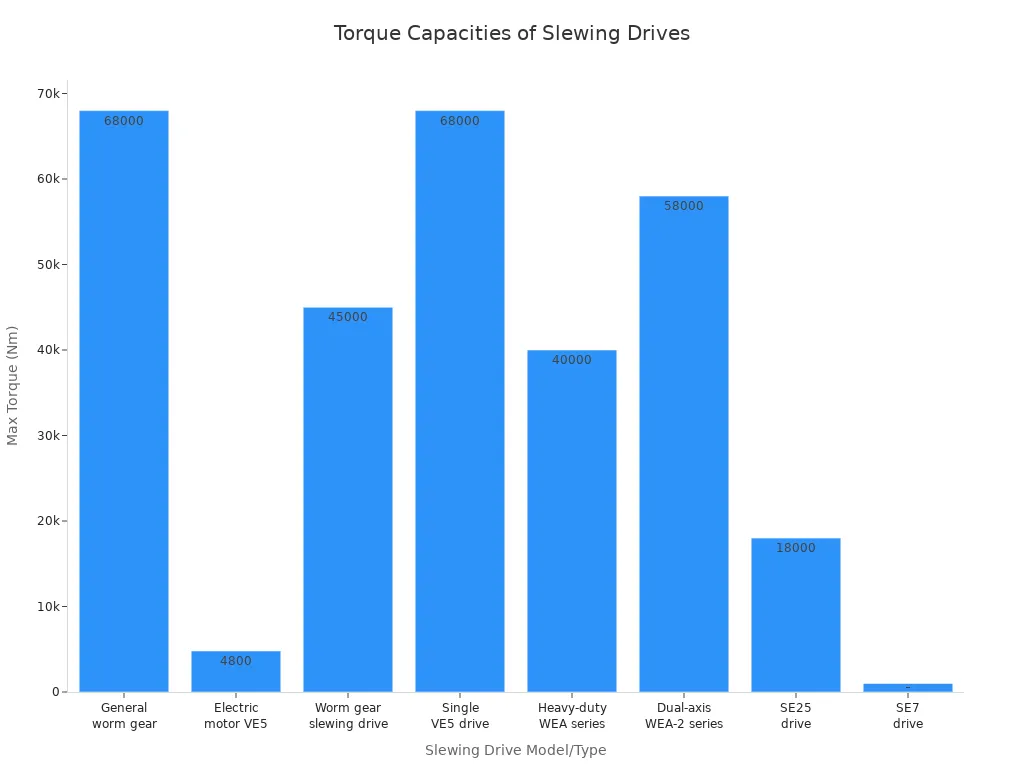

I-Slewing iletha ukunyakaza okujikelezayo phakathi kwezingxenye zomshini, isekela imithwalo emikhulu ngokunemba. Imishini esindayo, njengama-cranes nama-wind turbines, incike kumabheringi athuthukile nokushayela. Ii-hydraulic slewing driveiqinisekisa ukudluliswa kwe-torque okuthembekile.Amandla okulayisha ajwayelekile ahlanganisa ububanzi obubanzi:

| I-Slewing Drive Model/Uhlobo | I-Torque Range (Nm) | I-Max Static Torque (kNm) | Izinhlelo zokusebenza |

|---|---|---|---|

| Imishini evamile yokubulala izikelemu | 365 - 68,000 | Kufika ku-190 | Ama-Cranes, izinjini zomoya, ama-solar trackers |

| Imoto kagesi i-VE5 slewing drive | 4,800 | N/A | Ukuhanjiswa kwegiya lezikelemu |

| Ukushayela kwegiya lezikelemu | 2,500 - 45,000 | 190 | 360° swivel, umthwalo we-axial ophezulu |

| Idrayivu yokushutha eyodwa VE5 | 500 - 68,000 | N/A | Ukulandelela ilanga |

| Uchungechunge lwe-WEA olusindayo | 8,000 - 40,000 | N/A | Imishini yezolimo |

| Uchungechunge lwe-Dual-axis WEA-2 | 16,200; 19,440; 48,000; 58,000 | N/A | Izindlela eziningi, ezithwala kanzima |

| I-Worm gear slewing drive i-SE25 | 18,000 | N/A | Ama-Cranes, ama-excavators |

| I-Worm gear slewing drive SE7 | 1,000 | N/A | Ukulayisha okuphezulu, ukulawula okunembayo |

Okuthathwayo Okubalulekile

- Izindlela zokugeqa zinika amandla ukuzungezisa okubushelelezi, okunembe ngokusebenzisa amabherengi nezinto eziginqikayo ezisekelayoimithwalo esindayofuthi unciphise ukungqubuzana.

- Ukusatshalaliswa okufanele komthwalo kanye nokulawulwa kwe-torque kumadrayivu abulalayo kuqinisekisa ukunyakaza okuzinzile nokunembile, okubalulekile emishinini esindayo njengama-cranes nezinjini zomoya.

- Ukunakekelwa okuvamile, okuhlanganisa ukugcotshwa okufika ngesikhathi kanye nokuhlolwa, kwandisa ukuphila kwezingxenye zokubulala futhi kugcina okokusebenza kusebenza ngokuphepha nangempumelelo.

Izingxenye Eziyinhloko Zezindlela Zokugwaza

Slewing Izindandatho kanye Bearings

Amasongo nama-bearings akha umgogodla wezindlela zokuhlaba. Lezi zingxenye ezinkulu, eziyindilinga zisekela sonke isisindo sesakhiwo esijikelezayo futhi zinike amandla ukunyakaza okubushelelezi, okulawulwayo. Iringi yokushaya ngokuvamile iqukethe amasongo angaphakathi nangaphandle, anezici ezigoqayo ezihlanganiswe phakathi kwawo. Amabhereli aphatha i-axial, i-radial, nemithwalo yesikhashana, eqinisekisa ukuzinza nokusebenza okuthembekile. Ithebula elingezansi lifingqa leizingxenye eziyinhloko kanye nemisebenzi yazo:

| Isakhi | Umsebenzi |

|---|---|

| Iringithoni | Isekela imithwalo esindayo futhi ivumela ukuzungezisa okubushelelezi. |

| Amabhere | Phatha i-axial, i-radial, nemithwalo yesikhashana ukuze uzinze. |

| I-Driving Mechanism | Ihlinzeka nge-torque yokuzungezisa, ngokuvamile ngama-motor kagesi noma awe-hydraulic. |

Izinto ezigoqayo

Izinto ezigoqayo, njengamabhola noma ama-roller, zinciphisa ukungqubuzana futhi zigqoke ngaphakathi kwendandatho yokugenca. Ukuhlelwa nohlobo lwazo kuthinta ngqo ukusebenza kahle nokuqina.Amaphuzu amane amabhola okuxhumanaukusabalalisa imithwalo ngamaphuzu amane, okwandisa ukuguquguquka. Ama-cross roller bearings, anama-roller asethwe kuma-engeli angakwesokudla, anikezela ngokusatshalaliswa komthwalo okuphezulu kanye nokuqina. Ama-roller bearings anemigqa emithathu ahlinzeka ngomthamo ophezulu kakhulu wokulayisha, okuwenza alungele izinhlelo zokusebenza ezisindayo. Ukukhethwa kwe-elementi eginqikayo kunomthelela ekusebenzeni komshini neminyaka yokuphila.

Amagiya kanye nama-Drive Systems

Amagiya kanyeamasistimu okushayeladlulisa amandla asuka kumotho aye eringini yokujula. Izindlela eziningi zokubulala ziyasetshenziswaukulungiselelwa kwegiya lezikelemu, lapho i-worm shaft ishayela khona igiya le-perpendicular. Lokhu kusetha kunciphisa isivinini futhi kwenyusa i-torque, ebalulekile emishinini esindayo. Imiklamo yesimanje ivame ukufaka ubuchwepheshe be-hourglass worm, okuthuthukisa ukubandakanyeka kwamazinyo nokuqina. Amasistimu we-Dual-eksisi kanye ne-dual-drive athuthukisa amandla nokulawula.

Izimpawu kanye Nokugcotshwa

Izigxivizo nokugcoba kuvikela izingxenye zangaphakathi futhi kuqinisekise ukusebenza kwesikhathi eside. Izigxivizo zekhwalithi ephezulu zivimbela ukungcola ekungeneni kwe-bearing.Lubrication efaneleinciphisa ukungqubuzana, ivimbele ukuthintana kwensimbi nensimbi, futhi ikhiphe ukushisa. Ukugcinwa njalo kanyeubuchwepheshe obuphambili bokugcoba, njengeukugcoba okuqinile, andise ukuphila okuzalayo nokwethenjelwa. Amasistimu okugcoba anakekelwa kahle nawo anciphisa umsindo nokudlidliza, asekele ukusebenza kahle.

Indlela Izindlela Zokubulala Ezisebenza Ngayo

Ukusebenzisana Kwezinsimbi Zokuzungezisa

Izindlela zokuhlikihla zithola ukuzungezisa okushelelayo ngesenzo esihlanganisiwe sezingxenye ezibalulekile ezimbalwa. Inqubo yembuleka ngokulandelana okunembile:

- Ii-slewing bear ihlezi phakathi kwezingxenye ezimbili eziyinhloko zomshini, njengesisekelo se-crane kanye nesakhiwo sayo esiphezulu esijikelezayo.

- Amandla angaphandle, okuhlanganisa isisindo semishini kanye nemithwalo yokusebenza, asebenza ekuthwaleni.

- Izakhi ezigoqayo—amabhola noma ama-roller—hamba phakathi kwamasongo angaphakathi nangaphandle okuthwala.

- Lawa ma-elementi aginqikayo asabalalisa umthwalo osetshenzisiwe ezindaweni zawo zokuxhumana kanye nemigwaqo eklanywe ngokukhethekile.

- Imigwaqo yomjaho, enemisele elungiselelwe, inciphisa ingcindezi futhi iqinisekise ukwabelana ngomthwalo.

- Kokubili izakhi eziginqikayo kanye nejiyomethri yomjaho imelana nokuguquka, ngisho nangaphansi kwemithwalo esindayo.

- Lokhu kumelana kuvumela ukujikeleza okubushelelezi, okuphansi kwe-friction phakathi kwezingxenye ezixhunyiwe.

- Ukuhlelwa okunembile kwezinto eziginqikayo kanye nejometri yemigwaqo yomjaho kunika amandla ukulawula ukunyakaza okunembile.

- Njengoba umshini uzungeza, ukuthwala kuyaqhubeka kusabalalisa kabusha imithwalo eshintshayo ukuze kugcinwe ukuzinza.

- Izinto ezithuthukisiwe kanye nezinqubo zobunjiniyela zandisa impilo yesevisi ye-beraring futhi ziqinisekisa ukusebenza okuthembekile ngaphansi kwezimo ezihlukahlukene.

Qaphela: Ukugqoka nokukhathala kumelela izindlela zokwehluleka ezivame kakhuluekubulaleni ama-bearings. Lezi zinkinga zivame ukuvela ngenxa yemithwalo yama-cyclic, ukungqubuzana, izinselele zokugcoba, noma ukuhlanganisa okungalungile. Ezinye izinkinga ezingase zibe khona zihlanganisa ukuphuka, ukugqwala, nokuguqulwa. Ukuhlola njalo nokunakekela kusiza ukuvimbela lokhu kwehluleka futhi kuqinisekise ukusebenza okuphephile, okuthembekile.

Ukusatshalaliswa komthwalo kanye nokusekela

Ama-slewing bearings kufanele aphathe izimo eziyinkimbinkimbi zomthwalo ngesikhathi sokusebenza. Le mithwalo ihlanganisa:

- Imithwalo ye-Axial:Amandla asebenza ngokuhambisana ne-eksisi yokuzungezisa, ngokuvamile abangelwa isisindo sezinto zokusebenza noma amathonya angaphandle.

- Imithwalo yeradial:Amandla asebenza ngokuhambisana ne-eksisi, njengalawo adalwa umoya noma imithelela ye-centrifugal.

- Ukulayishwa kwesikhashana:Inhlanganisela yamandla e-axial kanye ne-radial, ngokuvamile akhiqizwa ukunyakaza nesisindo somshini.

Ukusatshalaliswa komthwalo kuyo yonke i-bearing akuvamile ukufana. Ukugoba komzila womjaho kanye nenani lama-elementi agingqikayo kuthonya indlela imithwalo esabalele ngayo kuyo yonke i-bearing. Onjiniyela bathuthukisa ukusatshalaliswa komthwalo ngokulungisa inombolo nosayizi wezinto ezigoqayo, i-engeli yokuxhumana, kanye nephrofayela yomjaho.

Izindlela ezimbalwa zobunjiniyela zisiza ekugcineni ukwesekwa kokulayisha okulinganayo:

- Ukugcoba ngendlela efanele kunciphisa ukungqubuzana nokuguga, isekela ukusatshalaliswa komthwalo ofanayo.

- Ukukhetha amafutha alungile—asuselwa ku-lithium, asekelwe ku-calcium, noma asekelwe ku-polyurea—kuqinisekisa ukusebenza kahle kwezimo ezithile zokusebenza.

- Izithasiselo ezifana ne-molybdenum disulfide (MoS₂) zithuthukisa umthamo wokuthwala umthwalo kanye nezakhiwo zokulwa nokugqokwa.

- Ukunamathela ezinkathini zokugcoba ezinconyiwe kanye nenani kuvimbela ukuguga ngaphambi kwesikhathi kanye nengcindezi engalingani.

- Ijometri yokuxhumana enamaphuzu amaneivumela umugqa owodwa wamabhola ukusekelai-axial, i-radial, nemithwalo yesikhashanakanyekanye.

- Ukulungiswa kwangaphakathi kokugunyazwa kuhlanganisa ukungahambi kahle nokunwetshwa kokushisa, kugcina ukunemba kokujikeleza.

- Ukukhiqiza okunembayo, okuhlanganisa ukwenziwa kwemishini ye-CNC nokuqina kwe-induction, kukhiqiza imigwaqo yomjaho yekhwalithi ephezulu ekwazi ukumelana nemithwalo eguqukayo.

- Ukuqina okuphezulu nokwakheka okuhlangene kunciphisa isisindo sohlelo futhi kusekela imithwalo ye-eccentric noma ye-offset ngempumelelo.

Ithiphu:Imiklamo eyenziwe lula enezingxenye ezimbalwa ayigcini nje ngokwenza kube lula ukuhlanganisa nokunakekela kodwa futhi inomthelela ekusebenzeni okungaguquki ngisho nokusabalalisa umthwalo.

I-Torque Transmission and Control

Ukudluliswa kwe-torque kusenhliziyweni yokusebenza kwemishini yokubulala. Ii-torque yokudlulisa igiyakusukela emthonjeni wamandla omshini—kungaba injini kagesi noma ye-hydraulic—kuya esakhiweni esijikelezayo. Le nqubo inika amandla ukuzungezisa okuvundlile eduze kwe-eksisi eqondile, okuvumela ukuma okunembayo kwemithwalo esindayo.

Izici ezibalulekile zokudluliswa kwe-torque nokulawula zifaka:

- Iinjini ikhiqiza i-torque, edlula ohlelweni lokudlulisela. Lolu hlelo lungasebenzisa ama-pinion, amagiya wezikelemu, noma ezinye izinhlobo zamagiya.

- I-slewing bear ithola i-torque edlulisiwe, isekela i-axial, i-radial, nemithwalo yesikhashana ngenkathi ivumela ukuzungezisa okulawulwayo.

- Ukuthunyelwa kwegiya lezikelemu kunikeza isici sokuzikhiya, esiza ukubamba imithwalo ngokuphepha futhi sivumele ukulawula okunembayo okujikelezayo.

- Umhlangano we-slewing drive uhlanganisa isistimu yezindlu nokuvala ukuze kuvikelwe izingxenye zangaphakathi nokugcina ukusebenza okungaguquki.

- Zonke izingxenye zisebenza ndawonye ukuze zinikeze ukunyakaza okunembile, okushelelayo okujikelezayo nokugcina umthwalo uzinzile ngesikhathi sokusebenza.

| Ipharamitha | Inani/Incazelo |

|---|---|

| I-Slewing Drive Type | I-Spur gear slewing drive |

| Isilinganiso segiya | 9:1 |

| I-torque yokuphuma elinganiselwe | ~37 kN·m(imodeli ejwayelekile ye-heavy-duty) |

| Ububanzi Besikhungo Sokuzungeza | 955 mm |

| Ubude Obuphelele nge-adaptha | 180 mm |

| I-Gear Backlash | ≤ 0.40 mm |

| Isicelo | Imishini esindayo enezikhathi ezinkulu zokutshekisa kanye nemithwalo esindayo |

| Ukuvumelana nezimo | Amadrayivu ama-slewing amakhulu atholakalayo anobubanzi obufika ku-2300 mm kanye ne-torque ephakeme |

Imishini yesimanje yokubulala ihlanganisa ubunjiniyela obuqinile, izinto ezithuthukisiwe, kanye nokukhiqiza okunembayo ukuletha ukudluliswa nokulawula kwetorque okuthembekile. Lokhu kuqinisekisa ukuthi imishini esindayo ingasebenza ngokuphepha nangempumelelo, ngisho nangaphansi kwezimo ezinzima.

Izinhlobo Nokucatshangelwa Okungokoqobo

I-Hydraulic Slewing

Amasistimu we-Hydraulic Slewing asebenzisa uketshezi olucindezelwe ukwenza i-torque ephezulu kanye nokulawula okubushelelezi, okulinganayo. Lezi zinhlelo zihamba phambili ezinhlelweni ezisindayo, njengama-cranes nama-excavators, lapho ukusebenza okuqhubekayo ngaphansi kwemithwalo ebalulekile kuyadingeka.I-Hydraulic Slewinginikeza ukusebenza kahle kwemishini ephezulu nokusebenza okuthembekile ezindaweni ezinokhahlo. Ama-opharetha ayazuza ekuhambeni okunembayo ngesivinini esiphansi, okubalulekile ekuphakamiseni nasekubekeni izinto ezisindayo.Amasistimu we-Hydraulic Slewingzidinga ukuhlanganiswa namaphampu amanzi kanye nokuphathwa kwamanzi, okwenza ukufakwa nokugcinwa kube nzima kunezinye izindlela zikagesi. Kodwa-ke, ziletha amandla aphezulu okudonsa futhi zingasebenza ngaphandle kokushisa ngokweqile ngesikhathi sokusetshenziswa okunwetshiwe. Iukusebenza kahle kweHydraulic Slewing kuyathuthuka ezinhlelweni ezixubile, okunciphisa amandla aphezulu kanye nokusetshenziswa kwamandla.

Ezinye Izinhlobo Zezindlela Zokubulala

Imishini yesimanje isebenzisa izinhlobo ezimbalwa zemishini yokubulala, ngayinye enezici ezihlukile.Amagiya egiya lezikelemu ahlinzeka ngokuncishiswa kwegiya eliphezulu endaweni ehlangenefuthi unikeze amandla okuzivalela, okuthuthukisa ukuphepha. Amadrayivu egiya e-Spur asebenzisa ama-shaft ahambisanayo namazinyo aqondile, okuwenza afanelekele izitimela zamagiya ezilula.Imishini kagesi yokubulala ihlanganisa amagiya ezikelemu namabheringi okuhlaba, iletha ukuzungezisa okunembayo, kwetorque ephezulu kanye nezindawo zokubamba ezivikelekile.Ithebula elingezansi lifingqa izinhlobo ezijwayelekile zama-slewing kanye nokusetshenziswa kwazo:

| Uhlobo lwe-Slewing Bearing | Izimpawu Zesakhiwo | Izicelo Ezijwayelekile Emishinini Yesimanje |

|---|---|---|

| Amaphuzu amane Xhumana Ball Slewing Bearing | Isakhiwo esilula, sisekela i-bidirectional axial kanye namandla e-radial, amandla athile omzuzwana ogumbuqelayo | Ama-cranes amancane, imishini yokuphatha impahla |

| Ibhola elinemigqa ekabili enobubanzi obuhlukile | Imigqa emibili yamabhola, umthamo wokulayisha olungiselelwe kanye nempilo yesevisi | Imishini yembobo yosayizi omaphakathi, ama-cranes wokupakisha |

| I-Crossed Cylindrical Roller | Isikhathi esiphezulu sokugumbuqela kanye namandla e-axial force, ukunemba okuphezulu kokujikeleza | Ama-cranes amakhulu echwebeni, ama-cranes amabhuloho |

| I-Cylindrical Roller enemigqa emithathu | Indawo yokuxhumana enkulu, isekela izikhathi ezinkulu ze-axial, i-radial, kanye nokugingqika | Imishini yembobo emikhulu kakhulu, esindayo |

Isondlo Nokunakekela

Ukugcinwa okufanele kuqinisekisa ukuphila isikhathi eside nokuthembeka kwezindlela zokuhlaba.Abasebenzisi kufanele bahlole amabhawodi ngaphambi kokusebenza ngakunye nangemuva kwamahora okuqala ayi-100 okusebenza, bese kuba ngamahora angu-300, futhi njalo ngemva kwamahora angu-500.Izikhathi zokuthambisa zisukela njalo emahoreni angama-200 kuye kwangama-500, kuye ngomthwalo nendawo ezungezile. Ezimweni ezinzima, njengomswakama ophezulu noma uthuli, imijikelezo yokugcoba kufanele incishiswe. Ukuhlola okuvamile kusiza ukuthola ukuguga, ukulimala, noma ukungcola kusenesikhathi. Ukuhlanza, ukugcotshwa okulungile, nokushintshwa ngesikhathi kwezingxenye ezigugile kuvimbela ukukhululeka ngokweqile, ukuvuza kukawoyela, nokushisa ngokweqile.

Izicelo Ezivamile

Imishini yokugenca idlala indima ebalulekile ezimbonini eziningi.Imishini yokwakha neyezimboni ithembele kubo ngokuzungezisa okungu-360-degree kanye nokwesekwa komthwalo osindayo. Izicelo ezijwayelekile zifaka:

- Ama-excavators nama-cranes okuphakamisa kanye nokuphatha impahla

- Imishini yamahlathi kanye nama-forklift

- Imishini yokumba izimayini namaloli amabhokisi

- Izimoto eziphakeme kakhulu namarobhothi ezimboni

Lezi zindlela ziphinde zivele emikhakheni yasolwandle, amandla avuselelekayo, i-aerospace, kanye ne-automation, isekela ukunyakaza okunembayo nokuzinza.

Izindlela zokuhlikihla zivumela ukuzungezisa okunembe, okusindayo kuzo zonke izimboni, ukusuka kuma-cranes kuye kuma-wind turbines. Imiklamo yabo ethuthukisiwe, njengeimigqa emithathu ye-roller kanye ne-cross roller bearings, ukusekela imithwalo eyinkimbinkimbi futhi uqinisekise ukusebenza okuthembekile.Ukugcinwa njalo, okuhlanganisa amasistimu e-Hydraulic Slewing, akhulisa isikhathi sokuphila kwemishini kanye nokuphepha kokusebenza. Izinqubo ezintsha eziqhubekayo ziyaqhubeka nokuqhuba ukusebenza kahle nokunemba.

FAQ

Uyini umsebenzi oyinhloko we-slewing drive?

A ukushayelainika amandla ukunyakaza okujikelezayo okulawulwayo phakathi kwezingxenye ezimbili zomshini. Isekela imithwalo esindayo futhi iqinisekisa ukuma okunembile kumishini yezimboni.

Ngabe opharetha kufanele bagcobe kaningi kangakanani ama-slewing bearings?

Ama-operators kufanele agcobe ama-slewing bearings njalo emahoreni angama-200 kuya kwangama-500. Izindawo ezinokhahlo zingadinga ukugcotshwa okuvamile ukuze kugcinwe ukusebenza kahle.

Ingabe izindlela zokuhlaba zingasingatha kokubili imithwalo ye-axial ne-radial?

Yebo. Izindlela zokuhlikihla zisekela imithwalo ye-axial, radial, nesikhashana. Umklamo wabo usabalalisa lawa mandla ngendlela efanele, uqinisekisa ukuzinza kanye nempilo ende yenkonzo.

Isikhathi sokuthumela: Jul-25-2025