Igiya ye-spur inamazinyo athe ngqo kwaye ijikeleza kwi-axis ehambelanayo. Igiya ye-pinion, ehlala incinci kwisibini, idibanisa i-spur gear ukuhambisa intshukumo. Ngokudibeneyo, iigiya ze-spur kunye ne-pinion zidlulisela ngokufanelekileyo amandla kumashishini amaninzi, kubandakanya iimoto, i-aerospace, kunye ne-Hydraulic Slewing applications.

Izinto eziphambili zokuThatha

- Iigiya ze-Spur kunye ne-pinion zisebenza kunye ukuhambisa amandla ngokufanelekileyo phakathi kweeshafu ezinxuseneyo, kunye ne-pinion idla ngokuba sesona sixhobo sincinci sokuqhuba.

- Ezi zixhobo zibonelela kakhuluukusebenza kakuhle, rhoqo ngaphezu kwe-98%, ibenza balungele oomatshini abafuna ulawulo oluthembekileyo noluchanekileyo lwentshukumo.

- Izixhobo ze-Spur kunye ne-pinion zisetyenziswa ngokubanzi kumashishini amaninzi, kubandakanya iimoto, i-aerospace, kunyehydraulic slawing, ngenxa yokuqina kwazo kunye nokulula ukugcinwa.

Zisebenza njani iSpur kunye nePinion Gears

IiMechanics ezisisiseko

Iigiya ze-Spur kunye ne-pinion zisebenza kwimigaqo elula kodwa echanekileyo yomatshini. Ezi zixhobo zihambisa intshukumo ejikelezayo phakathi kweeshafu ezinxuseneyo, zigcina umlinganiselo wesantya esingaguqukiyo. Iprofayili yamazinyo e-involute, imilo egobileyo, iqinisekisa i-meshing egudileyo kunye nesantya esizinzileyo ngexesha lokusebenza.

- Iisangqa sepitchsisangqa sentelekelelo esidlula kwindawo apho amazinyo egiya ezimbini adibana khona. Le ndawo ibizwa ngokuba yipitch point, kulapho iigiya zihambisa khona ngokufanelekileyo.

- Isenzo se-Conjugate sithetha ukuba njengoko izinyo legiya elinye lityhala elinye, izinyo eliqhutywayo lihamba ngomlinganiselo ogqibeleleyo, ligcina umlinganiselo wesantya.

- Umlinganiselo wegiya uxhomekeke kwinani lamazinyo okanye ububanzi bezangqa zepitch. Igiya enkulu edityaniswe nepinion encinci yonyusa i-torque kodwa iyanciphisa isantya.

- Amagama aphambili abandakanya:

- Imodyuli(umlinganiselo wemetric yobungakanani bezinyo)

- I-diametral pitch(umlinganiselo wobukhosi)

- I-angle yoxinzelelo(uqhele ukuba ngama-20°)

- Umlinganiselo woqhagamshelwano(umndilili yenani lamazinyo adityanisiweyo)

Phawula:Umlinganiselo woqhagamshelwano unceda ukwabelana ngomthwalo phakathi kwamazinyo, okwenza inkqubo yegiya ibe yomelele kwaye ibe lula.

Ukukhetha izinto eziphathekayo kudlala indima ebalulekileyo ekusebenzeni kwezixhobo. Intsimbi, ubhedu, kunye ne-thermoplastics njengenylon okanye i-acetal zikhetho eziqhelekileyo. Intsimbi inika amandla kunye nokuqina, ngelixa iiplastiki zinciphisa ingxolo kwaye zixhathisa ukubola. Ubhedu kunye nensimbi engenasici zisebenza kakuhle kwiindawo ezimanzi okanye ezinzima. Iinjineli zihlala zisebenzisaunyango lobushushu ezifana carburizing okanye induction lukhuniukwandisa ukuqina komphezulu kunye nokwandisa ubomi bezixhobo.

Iseti eqhelekileyo ye-spur kunye ne-pinion isebenzisa i-pinion njengesixhobo sokuqhuba. Amazinyo ayo adibene nalawo e-spur gear,ukuhambisa intshukumo kunye netorque. Amazinyo athe tye eegiya ze-spur avumela ukuhanjiswa kwamandla okusebenzayo phakathi kweeshafu ezihambelanayo.

Intshukumo kunye noTshintsho lwaMandla

Ukudibana phakathi kwamazinyo e-spur kunye ne-pinion gear ichanekile kwaye iyasebenza. Amazinyo e-mesh kwizangqa zawo zepitch, apho ukuhanjiswa kwentshukumo ejikelezayo kunye ne-torque kwenzeka. Njengoko iphini lijikeleza, amazinyo atyhalana kumazinyo e-spur gear, nto leyo ebangela ukuba i-spur gear ijike. Indawo yoqhagamshelwano ihamba ecaleni kweumgca wesenzo, umgca wentelekelelo okhokela ukuhanjiswa kwamandla phakathi kweegiya.

- Amazinyo egiya abandakanyeka kwisangqa se-pitch, ukuhambisa intshukumo kunye ne-torque.

- Indawo yoqhagamshelwano ihamba ngomgca wesenzo, iqinisekisa ukuhanjiswa kwamandla okugudileyo.

- Iiprofayili zezinyo ezibandakanyayo zinciphisa imithwalo yempembelelo kwaye zivumele ukubandakanyeka okuzinzileyo.

- Izinto zejiyometri ezifana nedayamitha yesangqa sepitch, i-angle yoxinzelelo, kunye ne-backlash inefuthe kwindlela umnatha weegiya ngokutyibilikayo.

- I-backlash, i-gap encinci phakathi kwamazinyo, ikhusela i-jamming kwaye ivumela ukwanda kwe-thermal.

- I-angle ye-meshing ichaphazela ukungqubuzana kunye nengxolo ngexesha lokusebenza.

- Ezi mpawu zenza ukuba i-pinion iqhube i-spur gear ngokusebenza okuphezulu kunye nokuthembeka.

Umlinganiselo wegiya, ochazwa njengenani lamazinyo kwisixhobo esiqhutywayo esahlulwe ngenani kwisixhobo sokuqhuba, sichaphazela ngqo isantya kunye netorque. Umzekelo, a2:1 gear ratiokuthetha ukuba igiya eqhutywayo ijika kwisiqingatha sesantya sepiyoni kodwa ihambisa kabini itorque. Olu lwalamano luvumela iinjineli ukuba zenze iinkqubo zegiya ezihambelana neemfuno ezithile zokusebenza.

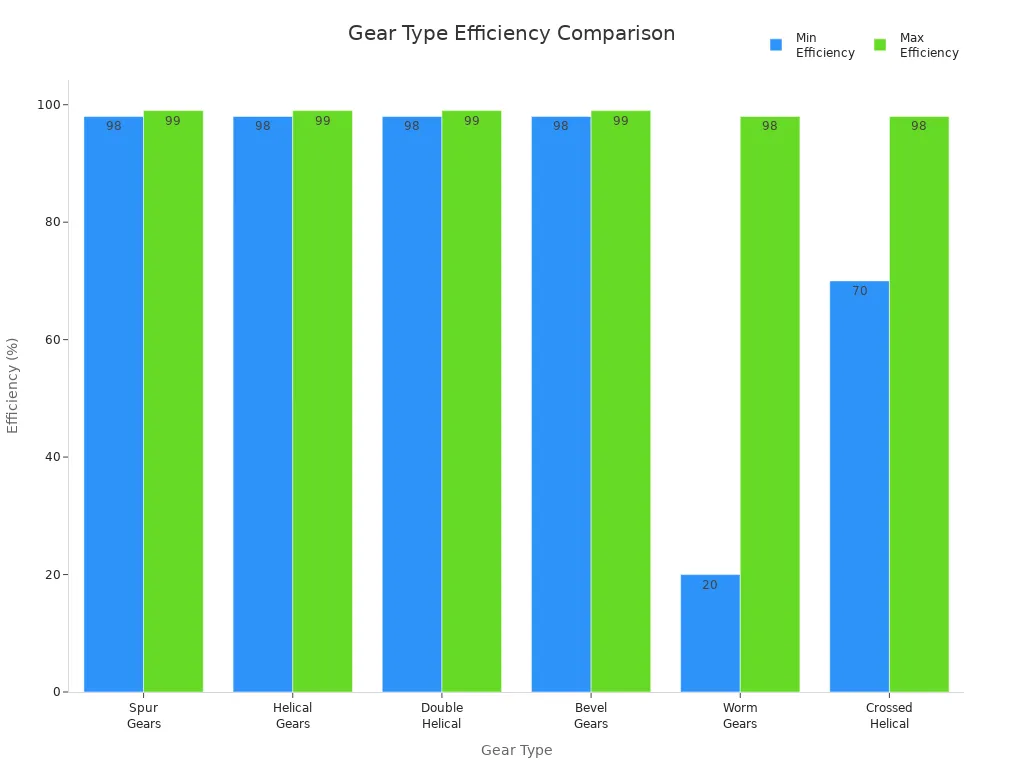

| Uhlobo lweGear | Uluhlu olusebenzayo | Amanqaku aPhambili kuMsebenzi noLahleko |

|---|---|---|

| Spur Gears | 98-99% | Ukusebenza okuphezulu kakhulu; ilahleko encinci ikakhulu ngenxa yokukhuhlana kwamazinyo kunye nokuthanjiswa kwe-lubrication |

| Iigiya zeHelical | 98-99% | Ingaphantsi kancinci kune-spur ngenxa ye-axial thrust kunye nentshukumo yokutyibilika |

| I-Helical ephindwe kabini | 98-99% | Ukuthelekiswa nezixhobo ze-spur kunye ne-helical |

| Bevel Gears | 98-99% | Ukusebenza okuphezulu kodwa kuphantsi kune-spur ngenxa yesenzo sokutyibilika |

| Iigiya zeNtshulube | 20-98% | Ukusebenza okuphantsi kakhulu, kuxhomekeke kakhulu kumlinganiselo wegiya kunye neemeko |

| Wawela i-Helical | 70-98% | Ukusebenza okuphantsi ngenxa yokutyibilika kunye nokuzibandakanya kwamazinyo |

Iigiya ze-Spur kunye ne-pinion zivelele ekusebenzeni kwazo okuphezulu, ngokuqhelekileyo zifikelela kwi-98-99%. Oku kubenza balungele izicelo apho ilahleko yamandla encinci ibalulekile. Nangona kunjalo, iigiya ze-spur zinqabilevelisa ingxolo eninzi kuneegiya zehelicalkuba amazinyo azo asebenza ngesiquphe, ekhupha amandla ngesiquphe kwaye abangele ukungcangcazela. Iigiya ze-Helical, ezinamazinyo azo aneengile, zisebenza ngokuzolileyo ngakumbi kodwa zintsonkothile ngakumbi ukwenziwa.

Ukugcinwa kubalulekile ekusebenzeni okuthembekileyo kwezixhobo. Imiba eqhelekileyo ibandakanyaukunxitywa, ukungahambi kakuhle, kunye nokungathambi okwaneleyo. Ukuhlolwa rhoqo kunye nokuthambisa okufanelekileyo kunceda ukunqanda iingxaki ezinje ngepitting, spalling, and abrasive wear. Ukukhetha izixhobo ezifanelekileyo kunye nokugcina ulungelelwaniso oluchanekileyo lwandisa ubomi be-spur kunye ne-pinion gears, ukuqinisekisa ukuhanjiswa kwamandla okugudileyo kunye okusebenzayo kuluhlu olubanzi loomatshini.

Iimpawu eziphambili kunye neeyantlukwano

I-Spur Gear Design

Iigiya ze-Spur zibalasele kuzoamazinyo athe tye, ahamba ngokunxuseneyo kwi-axis yegiya. Olu luyilo luvumela uqhagamshelwano oluthe ngqo phakathi kwemiphezulu yezinyo, okubangelaukusebenza kakuhle-kaninzi ngaphezulu kwe-98%. Iigiya ze-Spur zihambisa intshukumo ejikelezayo phakathi kweeshafu ezinxuseneyo kwaye zinemilo elula ye-cylindrical. Uninzi lweegiya ze-spur zingaphandle, zinamazinyo kumphetho ongaphandle, okubangela ukuba igiya eqhutywayo ijikeleze kwelinye icala. Iigiya ze-spur zangaphakathi, ezinamazinyo ngaphakathi, zivumela isithuba esikufutshane se-shaft kunye ne-torque ephezulu kodwa zifuna ukwenziwa okunzima ngakumbi.

| Uphawu | Spur Gears | Ezinye Iintlobo zeGear (isiShwankathelo) |

|---|---|---|

| Uyilo lwamazinyo | Amazinyo athe tye angqamene neasi yegiya | I-Helical: amazinyo ane-angle; I-Bevel: i-conical; I-Worm: i-screw-like; Iplanethi: iigiya ezininzi zeeplanethi |

| Shaft Orientation | Iishafu ezinxuseneyo | I-Helical: ihambelana; I-Bevel: iyanqumlana; Intshulube: ayihambelani; Iplanethi: i-parallel/coaxial |

| Ukusebenza kakuhle | Phezulu (98% okanye ngaphezulu) | Helical: ngaphantsi kancinci; I-Bevel: iphakathi; Umbungu: ngaphantsi; Iplanethi: phezulu |

| Inqanaba Lengxolo | Kungxola ngesantya esiphezulu | I-Helical: ithule; I-Bevel: iphakathi; Ntshulube: cwaka; Iplanethi: iphakathi |

| Ukuntsonkotha & Iindleko | Ilula, ixabiso eliphantsi | I-Helical: inzima ngakumbi; I-Bevel: iphakathi; Intshulube: inzima; Iplanethi: intsonkothe kakhulu |

Inani lamazinyo kwi-spur gear lichaphazela umlinganiselo wegiya, ukuguda, kunye nokuhanjiswa komthwalo. Iinjineli zihlala zikhethaubuncinane amazinyo ali-18kuyilo olusemgangathweni ukunqanda ukuncipha kunye nokuqinisekisa ukusebenza okuthembekileyo.

Iimpawu zePinion Gear

Iigiya zePinion zidla ngokuba zizixhobo ezincinci kwiperi. Indawo yabo kuloliwe wegiya imisela i-advanteji yomatshini wenkqubo kunye nemveliso yamandla. Xa isetyenziswe kwiinkqubo ze-rack-and-pinion, iI-torque ye-pinion kunye nesantya sichaphazela ngokuthe ngqo amandla kunye nokuhamba kwe-rack. Kwizitimela zeplanethi,ukunyuswa okuguquguqukayo kweegiya zepinion kunceda ukuhambisa imithwalo ngokulinganayo, ukuphucula ukuqina kunye nokunciphisa uxinzelelo. Ukuqhubela phambili kwizinto eziphathekayo, ezifanaiipolima zekhabhoni zefayibha, baye bandisa ukuqina kwegiya yepinion, ebavumela ukuba baqhube kakuhle naphantsi kweemeko ezinzima.

Icebiso: Ukukhetha imathiriyeli efanelekileyo kunye nokubalwa kwamazinyo kwigiya yepinion kunokwandisa ubomi bayo kunye nokuphucula ukusebenza kwenkqubo.

I-Spur Gear vs. iPinion Gear

Iigiya ze-Spur kunye ne-pinion gears zabelana ngeenkqubo ezifanayo zokwenza, zombini zixhamlaimveliso elula kwaye enexabiso eliphantsi. Iigiya ze-Spur zisebenza njengoyena mqhubi okanye igiya eqhutywayo, ngelixa iigiya zepinion zihlala zisebenza njengegalelo okanye imveliso, ngakumbi kwi-rack-and-pinion okanye iinkqubo zeplanethi. Iigiya zeSpur zihlala ziphethe ukuhanjiswa kwamandla okujikelezayo, ngelixa iigiya zepinion zinokuguqula intshukumo ejikelezayo ibe yintshukumo yomda. Zombini iintlobo ngoku zisebenzisa iindlela zokuvelisa ezizinzileyo, ezifanakufutshane-netha ukubumbakwayeizinto ezinokuphinda zisetyenziswe, ukunciphisa impembelelo yokusingqongileyo. Umahluko wabo ngobukhulu, umsebenzi, kunye nokusetyenziswa kwenza ukuba nganye iyimfuneko kwiinkqubo oomatshini.

Ukusetyenziswa okuSebenzayo kunye nokuSwa kweHydraulic

Ukusetyenziswa kwansuku zonke kunye nemizekelo

Iigiya ze-Spur kunye ne-pinion zivela kwiimveliso ezininzi zemihla ngemihlakunye noomatshini bemizi-mveliso. Abantu bazifumana ezi zixhobo kwiimoto, kwiinkqubo zokuqhuba, nakwiibhayisekile. Emakhaya, oomatshini bokuhlamba, ii-blenders, kunye neewotshi zixhomekeke kwizixhobo ze-spur ukuze zisebenze kakuhle. Izixhobo zePinion zidlala indima ephambilii-rack kunye ne-pinion steering, ukunceda abaqhubi balawule izithuthi ngokuchanekileyo. Iifektri zisebenzisa ezi zixhobo kumabhanti okuhambisa, iimpompo, kunye noomatshini bokupakisha ukuhambisa iimveliso ngokufanelekileyo.

| Ishishini / Uhlobo loomatshini | Ukusetyenziswa okuSebenzayo kwe-Spur kunye ne-Pinion Gears |

|---|---|

| Iimoto | Ukunciphisa igiya, iinkqubo zokuqhuba, iiroli zendlela |

| Oomatshini boShishino | Iibhokisi zegiya, abahambisi, iimpompo, iicompressor, izixhobo zoomatshini |

| I-Aerospace | Ulawulo lwenqwelomoya, iinjini zenqwelomoya, izixhobo zokumisa |

| IsiZukulwana saMandla | Iiinjini zomoya, izikhululo zombane wamanzi |

| Ishishini leMilaphu | Ukusonta, ukuluka, ukudaya oomatshini |

| Iimveliso zabathengi | Iiwotshi, abashicileli, izixhobo zamandla |

| IziXhobo zaseKhaya | Oomatshini bokuhlamba, iiblenders, dryers |

| Iirobhothi kunye ne-Automation | Oomatshini be-CNC, iindlela ze-servo |

| Izithuthi ezinesantya esiphantsi kunye nezixhobo | Iibhayisekile, ii-kilns, ii-ball Mills |

| Oomatshini bokuSebenza | Iinkqubo zokubeka kunye ne-pinion |

Iinkqubo zokuSlewing ngeHydraulicsebenzisa iigiya ze-spur kunye ne-pinion ukujikelezisa izixhobo ezinzima njengeekhreyini kunye nabembi. Ezi nkqubo ziguqula amandla eenjini zehydraulic zibe yintshukumo elawulwayo, zenza kube lula ukuphakamisa kunye nokuguqula imithwalo emikhulu. Iuyilo oludibeneyo of Iidrive zeHydraulic Slewingivumelaufakelo lwe-plug-and-play, ukonga ixesha ebudeni bendibano.

Ukubaluleka koomatshini kunye neZixhobo

Iigiya ze-Spur kunye ne-pinion zixhasa imisebenzi ephambili yoomatshini abaninzi. Banika ukusebenza kakuhle okuphezulu, rhoqo ukufikelelaukuya kuthi ga kwi-98%, okunciphisa ukulahleka kwamandla kunye nokugcina izixhobo zisebenza kakuhle. Kwizicelo zeHydraulic Slewing, ezi giya ziqinisekisa ukujikeleza okuchanekileyo kunye ne-torque ezinzileyo, naphantsi kwemithwalo enzima. Izindlu ezitywiniweyo ze-Hydraulic Slewing drives zikhusela iigiya eluthulini nasemanzini, zizenza zithembeke kwiindawo ezirhabaxa.

Abavelisi bakhetha iigiya ze-spur kunye ne-pinion ukwenzela ukuqina kwazo kunye nokugcinwa lula. Iidrive zeHydraulic Slewing zihlala zisebenzisa izinto ezomeleleyo njengentsimbi okanye intsimbi engatyiwayo ukujongana nemisebenzi enzima. Ezi drives zinokusebenza kunye neenjini enye okanye ezimbini zehydraulic, zibonelela ngokuguquguquka koomatshini abahlukeneyo. Iinjineli zixabisa i-Hydraulic Slewing ngokukwazi kwayo ukuhambisa isantya esikhawulezayo kunye ne-torque ephezulu kwindawo edibeneyo.

Imarike yehlabathi koomatshini abasebenzisa i-spur kunye ne-pinion gears inkulu. Ngo-2024,ngaphezulu kwe-15 yezigidi zeeyunithi ze-spur zathengiswa, kunye necandelo lezemoto njengowona msebenzisi uphambili.Itekhnoloji yeHydraulic Slewingiyaqhubeka ikhula ngokubaluleka njengoko amashishini efuna izixhobo ezisebenza ngokufanelekileyo nezithembekileyo.

Iigiya ze-Spur zinezinyo ezithe tyekunye nokudlulisa amandla phakathi kweeshafti ezinxuseneyo.I-pinion, ihlala iyinto encinci, i-meshes nge-spur gear ukulawula isantya kunye ne-torque.

- I-Spur kunye ne-pinion gears zihambisaukusebenza kakuhle, ukuthembeka, kunye nokuchanekakoomatshini abafana neebhokisi zegiya, iirobhothi, kunye nezithuthi.

- Iinjineli zilindele ukusungulwa ngokutsha kunyeizinto ezikhaphukhaphu kunye nemveliso ephucukileyo, ukuqinisekisa ukuba ezi zixhobo zihlala zibalulekile kubugcisa bexesha elizayo.

FAQ

Ngowuphi umahluko omkhulu phakathi kwegiya ye-spur kunye ne-pinion gear?

Isixhobo se-spur sinokuba naluphi na ubungakanani, ngelixa i-pinion gear isoloko iyisixhobo esincinci kwisibini. I-pinion idla ngokuqhuba i-spur gear.

Kutheni iinjineli zikhetha iigiya ze-spur kunye ne-pinion koomatshini?

Iinjineli zikhetha iigiya ze-spur kunye ne-pinion ekusebenzeni kwazo okuphezulu, uyilo olulula, kunye nokuhanjiswa kwamandla okuthembekileyo. Ezi zixhobo zisebenza kakuhle koomatshini abaninzi kwaye zifuna ukulungiswa okuncinci.

Ngaba i-spur kunye ne-pinion gears ingaphatha imithwalo enzima?

Ewe. Iigiya ze-Spur kunye ne-pinion, ngakumbi ezo zenziwe ngezinto ezomeleleyo njengentsimbi, zinetotiphatha imithwalo enzimakwizixhobo ezinje ngeecranes, ii-excavators, kunye nee-gearbox zamashishini.

Ixesha lokuposa: Jul-25-2025