Sesebelisoa sa spur se na le meno a otlolohileng 'me se potoloha holim'a axis e bapileng. Giar ea pinion, hangata e nyane ka para, e hokahana le lisebelisoa tsa spur ho fetisa motsamao. Ka kopanelo, likere tsa spur le pinion li fetisetsa matla ka katleho liindastering tse ngata, ho kenyeletsoa lits'ebetso tsa likoloi, sefofane le Hydraulic Slewing.

Lintlha tsa bohlokoa

- Li-gear tsa Spur le pinion li sebetsa 'moho ho fetisetsa matla hantle lipakeng tsa li-shafts tse bapileng, hangata pinion e le lisebelisoa tse nyane tsa ho khanna.

- Lisebelisoa tsena li fana haholobokgabane bo phahameng, hangata ka holimo ho 98%, e etsa hore e be e loketseng bakeng sa mechine e hlokang taolo e tšepahalang le e nepahetseng ea motsamao.

- Li-gear tsa Spur le pinion li sebelisoa haholo liindastering tse ngata, ho kenyeletsoa likoloi, sefofane, le.hydraulic slawing, ka lebaka la ho tšoarella ha tsona le boiketlo ba tlhokomelo.

Kamoo Spur le Pinion Gears li Sebetsang Kateng

Mechanics ea Motheo

Lisebelisoa tsa Spur le pinion li sebetsa ho latela melao-motheo e bonolo empa e nepahetse. Li-gear tsena li fetisa motsamao oa rotary lipakeng tsa li-shafts tse bapileng, li boloka lebelo la lebelo le sa fetoheng. Profaele ea meno a involute, sebopeho se kobehileng, se netefatsa meshing e boreleli le lebelo le tsitsitseng nakong ea ts'ebetso.

- Thepitch circleke selikalikoe se inahaneloang se fetang moo meno a likere tse peli a kopanang teng. Ntlha ena, e bitsoang pitch point, ke moo likere li fetisang motsamao hantle haholo.

- Ketso ea conjugate e bolela hore ha leino le le leng la gear le sutumelletsa le leng, leino le khannoang le tsamaea ka mokhoa o phethahetseng, ho boloka lebelo le tsitsitseng.

- Karo-karolelano ea lisebelisoa e itšetlehile ka palo ea meno kapa bophara ba selikalikoe sa molumo. Gear e kholo e kopantsoeng le pinion e nyane e eketsa torque empa e fokotsa lebelo.

- Mantsoe a bohlokoa a kenyelletsa:

- Mojule(tekanyo ea metric ea boholo ba leino)

- Sekhahla sa diametral(tekanyo ea borena)

- Khatello angle(hangata ke 20°)

- Karolelano ea mabitso(karolelano ea palo ea meno a hokahaneng)

Hlokomela:Karo-karolelano ea ho kopana e thusa ho arolelana mojaro pakeng tsa meno, ho etsa hore tsamaiso ea gear e be matla le e bonolo.

Khetho ea thepa e phetha karolo ea bohlokoa ts'ebetsong ea lisebelisoa. Tšepe, boronse le thermoplastics tse kang nylon kapa acetal ke likhetho tse tloaelehileng. Tšepe e fana ka matla le nako e telele, ha polasetiki e fokotsa lerata le ho hanela kutu. Boronse le tšepe e sa hloekang li sebetsa hantle libakeng tse metsi kapa tse thata. Hangata baenjiniere ba sebelisakalafo ya mocheso joalo ka carburizing kapa induction hardnessho eketsa boima ba bokaholimo le ho lelefatsa bophelo ba lisebelisoa.

Sesebelisoa se tloaelehileng sa spur le pinion se sebelisa pinion joalo ka lisebelisoa tsa ho khanna. Meno a eona a kopane le a lisebelisoa tsa spur;tshisinyo le torque. Meno a otlolohileng a li-gear tsa spur a lumella hore ho be le phetisetso e nepahetseng ea matla pakeng tsa li-shafts tse bapileng.

Motion le Phetiso ea Matla

Tšebelisano lipakeng tsa meno a spur le pinion gear e nepahetse ebile e sebetsa hantle. Meno a mesh lisakeng tsa 'ona, moo ho fetisoang ha motsamao oa ho potoloha le torque. Ha liphion e ntse e bilika, meno a eona a sutumetsana le meno a spur gear, e leng ho etsang hore lisebelisoa tsa spur li fetohe. Sebaka sa ho kopana se tsamaea hammoho lemola oa ketso, mola o inahaneloang o tataisang phetiso ea matla lipakeng tsa likere.

- Meno a gear a kenella selikalikoeng sa molumo, a fetisa motsamao le torque.

- Sebaka sa ho kopana se tsamaea ka tsela ea ketso, ho netefatsa hore ho fetisoa ha matla a boreleli.

- Ho kenyelletsa lintlha tsa meno ho fokotsa litlamorao le ho lumella boitlamo bo tsitsitseng.

- Lintlha tsa geometric joalo ka bophara ba selika-likoe, sekhahla sa khatello, le backlash li susumetsa tsela eo mesh ea likere e tsamaeang hantle ka eona.

- Backlash, lekhalo le lenyenyane pakeng tsa meno, e thibela ho jamming le ho lumella ho atolosoa ha mocheso.

- Meshing angle e ama likhohlano le lerata nakong ea ts'ebetso.

- Likarolo tsena li nolofalletsa pinion ho khanna lisebelisoa tsa spur ka katleho e phahameng le ho ts'epahala.

Karo-karolelano ea li-gear, e hlalosoang e le palo ea meno a gear e khannoang e arotsoe ka palo ea lisebelisoa tsa ho khanna, e ama ka ho toba lebelo le torque. Ka mohlala, a2: 1 gear karo-karolelanoho bolela hore lisebelisoa tse khannoang li fetoha ka halofo ea lebelo la pinion empa li fana ka torque habeli. Kamano ena e lumella baenjiniere ho etsa lisebelisoa tsa lisebelisoa tse lumellanang le litlhoko tse itseng tsa tshebetso.

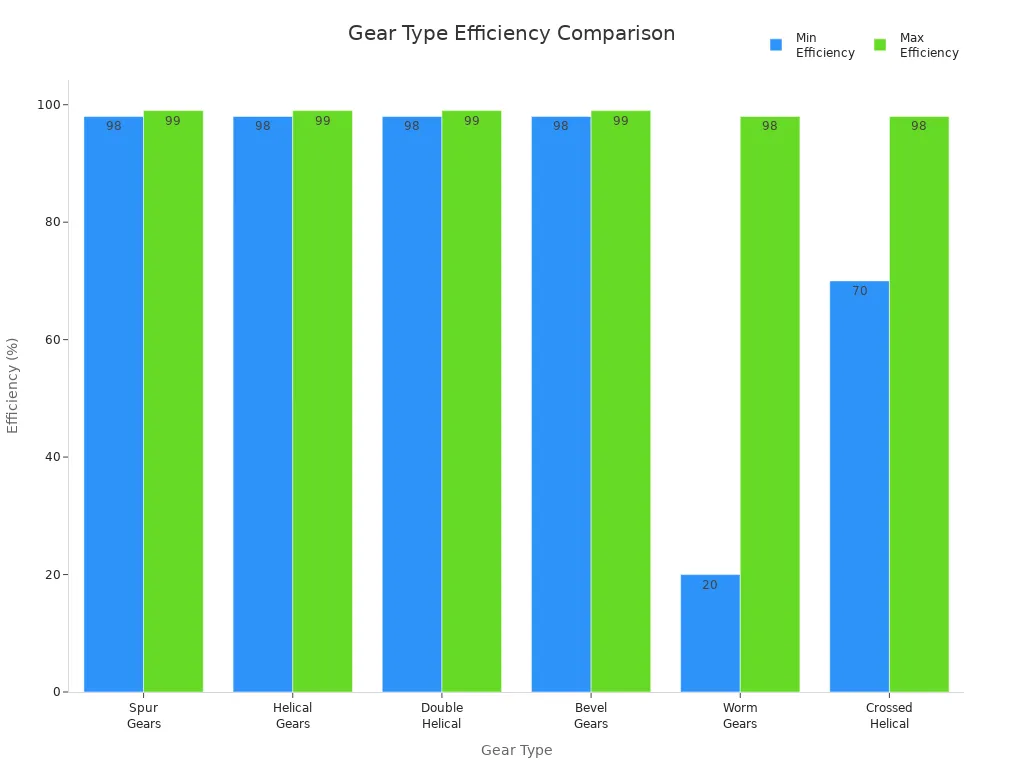

| Mofuta oa Gear | Katleho Range | Lintlha tsa Bohlokoa mabapi le Sebetsa le Tahlehelo |

|---|---|---|

| Spur Gears | 98-99% | Bokhoni bo phahameng haholo; tahlehelo e nyane haholo ka lebaka la ho hohlana ha meno le ho tlotsoa ha lubrication |

| Lisebelisoa tsa Helical | 98-99% | E tlase hanyane ho feta spur ka lebaka la axial thrust le ketso e thellang |

| Habeli Helical | 98-99% | E bapisoa le lisebelisoa tsa spur le helical |

| Bevel Gears | 98-99% | Bokgoni bo phahameng empa bo le tlase ho feta spur ka lebaka la ketso ya ho thella |

| Li-Gears tsa Worm | 20-98% | Ho sebetsa hantle ho tlase haholo, ho itšetlehile haholo ka tekanyo ea lisebelisoa le maemo |

| Sefapano sa Helical | 70-98% | Ts'ebetso e tlase ka lebaka la ho thella le ho sebetsana le meno a rarahaneng |

Lisebelisoa tsa Spur le pinion li hlahella ka katleho ea tsona e phahameng, hangata li fihla ho 98-99%. Sena se etsa hore e be tse loketseng bakeng sa lits'ebetso moo tahlehelo ea matla e leng bohlokoa haholo. Leha ho le joalo, li-gear tsa spur li atisa hohlahisa lerata ho feta helical gearhobane meno a bona a sebetsa ka tšohanyetso, a ntša matla ka tšohanyetso ’me a baka ho thothomela. Li-gear tsa Helical, tse nang le meno a mahlakoreng, li sebetsa ka khutso ho feta empa li rarahane ho feta ho li etsa.

Tlhokomelo ke ea bohlokoa bakeng sa ts'ebetso e tšepahalang ea lisebelisoa. Litaba tse tloaelehileng li kenyelletsaho roala, ho se tsamaisane hantle, le mafura a sa lekaneng. Ho hlahlojoa khafetsa le ho tlotsa ka mokhoa o nepahetseng ho thusa ho thibela mathata a kang ho phunya, ho senya le ho roala ha letlalo. Ho khetha lisebelisoa tse nepahetseng le ho boloka tumellano e nepahetseng ho eketsa nako ea bophelo ea lisebelisoa tsa spur le pinion, ho netefatsa phetisetso ea matla e boreleli le e sebetsang mecheng e mengata e fapaneng.

Likarolo tsa Bohlokoa le Liphapang

Spur Gear Design

Li-gear tsa Spur li ikhethile bakeng sa tsonameno a otlolohileng, a tsamaeang a bapile le axis ea gear. Moqapi ona o lumella ho kopana ka ho toba pakeng tsa libaka tsa meno, ho fella kats'ebetso e phahameng - hangata e feta 98%. Li-gear tsa Spur li fetisa motsamao oa rotary lipakeng tsa li-shafts tse bapileng 'me li na le sebopeho se bonolo sa cylindrical. Likarolo tse ngata tsa spur li ka ntle, li na le meno ka lehlakoreng le ka ntle, e leng se etsang hore lisebelisoa tse khannoang li potolohe ka lehlakoreng le leng. Li-gear tsa ka hare tsa spur, tse nang le meno ka hare, li lumella sebaka se haufi sa shaft le torque e phahameng empa li hloka tlhahiso e rarahaneng haholoanyane.

| Sebopeho | Spur Gears | Mefuta e meng ea Gear (Kakaretso) |

|---|---|---|

| Moqapi oa Leino | Meno a otlolohileng a bapileng le axis ea gear | Helical: meno a mahlakoreng; Bevel: conical; Seboko: sekoti-joaloka sekoti; Polanete: lisebelisoa tse ngata tsa lipolanete |

| Shaft Orientation | Li-shafts tse bapileng | Helical: e tšoanang; Bevel: intersecting; Seboko: se sa bapiseng; Polanete: e bapileng/coaxial |

| Katleho | Holimo (98% kapa ho feta) | Helical: tlase hanyane; Bevel: e itekanetseng; Seboko: tlase; Polanete: holimo |

| Boemo ba Lerata | Lerata ka lebelo le phahameng | Helical: e khutsitseng; Bevel: e itekanetseng; Seboko: khutsa; Polanete: e itekanetseng |

| Ho rarahana & Litšenyehelo | E bonolo, theko e tlaase | Helical: e rarahaneng haholoanyane; Bevel: e itekanetseng; Seboko: se rarahaneng; Polanete: e rarahane haholo |

Palo ea meno a spur gear e ama karo-karolelano ea lisebelisoa, boreleli le kabo ea mojaro. Hangata baenjiniere ba khethabonyane meno a 18bakeng sa meralo e tloaelehileng ho qoba ho fokotseha le ho netefatsa ts'ebetso e tšepahalang.

Litšobotsi tsa Gear ea Pinion

Hangata likere tsa pinion ke lisebelisoa tse nyane ka para. Boemo ba bona ka tereneng ea lisebelisuoa bo lekanya molemo oa mochine le tlhahiso ea matla. Ha e sebelisoa litsamaisong tsa rack-and-pinion, thetorque le lebelo la pinion li ama ka kotloloho matla le motsamao oa rack. Ka literene tsa lipolanete,ho hlongoa habonolo ha likere tsa pinion ho thusa ho aba meroalo ka ho lekana, ho ntlafatsa ho tšoarella le ho fokotsa khatello ea kelello. Tsoelo-pele ea thepa, joalo kalipolima tse matlafalitsoeng ka carbon fiber, li ekelitse ho tšoarella ha lisebelisoa tsa pinion, tse li lumellang ho sebetsa hantle le tlas'a maemo a thata.

Keletso: Ho khetha thepa e nepahetseng le palo ea meno bakeng sa lisebelisoa tsa pinion ho ka lelefatsa bophelo ba eona le ho ntlafatsa ts'ebetso ea sistimi.

Spur Gear vs. Pinion Gear

Li-gear tsa Spur le likere tsa pinion li arolelana mekhoa e tšoanang ea tlhahiso, ka bobeli li rua molemo ho tsonatlhahiso e bonolo le e theko e boima. Li-gear tsa Spur li sebetsa e le mokhanni oa mantlha kapa lisebelisoa tse khannoang, athe likere tsa pinion hangata li sebetsa joalo ka tlhahiso kapa tlhahiso, haholo lits'ebetsong tsa rack-and-pinion kapa lipolanete. Li-gear tsa Spur hangata li sebetsana le phetisetso ea matla a rotary, athe likere tsa pinion li khona ho fetolela motsamao oa rotary ho motsamao oa mola. Mefuta ena ka bobeli e se e sebelisa mekhoa e tsitsitseng ea tlhahiso, joalo kaho etsa sebopeho se haufi-netelelisebelisoa tse ka sebelisoang hape, ho fokotsa tšusumetso ea tikoloho. Liphapano tsa bona ka boholo, tšebetso le ts'ebeliso li etsa hore e 'ngoe le e' ngoe e be ea bohlokoa lits'ebetsong tsa mochini.

Lisebelisoa tse sebetsang le ho Slewing ka Hydraulic

Tšebeliso le Mehlala ea Letsatsi le Letsatsi

Lisebelisoa tsa Spur le pinion li hlaha lihlahisoa tse ngata tsa letsatsi le letsatsile mechine ea indasteri. Batho ba fumana likere tsena lipalangoang tsa makoloi, litsamaisong tsa lipalangoang esita le libaesekeleng. Malapeng, mechine e hlatsoang, li-blenders le lioache li itšetlehile ka lisebelisoa tsa spur hore li sebetse hantle. Lisebelisoa tsa pinion li bapala karolo ea bohlokoa horack le pinion setering, ho thusa bakhanni ho laola likoloi ka nepo. Lifeme li sebelisa likere tsena mabanteng a tsamaisang thepa, lipompong le mecheng ea ho paka ho tsamaisa lihlahisoa hantle.

| Mofuta oa Indasteri / Mechini | Lisebelisoa tse Sebetsang tsa Spur le Pinion Gears |

|---|---|

| Tsa makoloi | Phokotso ea li-gear, litsamaiso tsa ho tsamaisa, lirolara tseleng |

| Mechini ea Liindasteri | Li-gearbox, li-conveyors, lipompo, li-compressor, lisebelisoa tsa mochini |

| Sepakapaka | Litaolo tsa sefofane, lienjine tsa lifofane, lisebelisoa tsa ho lisa |

| Moloko oa Matla | Li-turbine tsa moea, liteishene tsa motlakase oa metsi |

| Indasteri ea Masela | Ho ohla, ho loha, ho daea mochini |

| Lihlahisoa tsa bareki | Lioache, likhatiso, lisebelisoa tsa motlakase |

| Lisebelisoa tsa ka Lapeng | Mechini ea ho hlatsoa, li-blenders, li-dryer |

| Liroboto le Boiketsetso | Mechini ea CNC, mekhoa ea servo |

| Likoloi le Lisebelisoa tse Tsamaeang Hantle | Libaesekele, li-kilns, liloala tsa bolo |

| Li-Actuator tsa Mechini | Sistimi ea rack le pinion |

Sistimi ea ho Slewing ea Hydraulicsebelisa likere tsa spur le pinion ho potoloha lisebelisoa tse boima joalo ka li-crane le liepolli. Lits'ebetso tsena li fetola matla a hydraulic motor hore e be motsamao o laoloang, ho etsa hore ho be bonolo ho phahamisa le ho fetola meroalo e meholo. Themoralo o kopaneng of Li-drive tsa Hydraulic Slewinglumella bakeng saho kenya plug-and-play, ho boloka nako nakong ea kopano.

Bohlokoa ho Mechini le Thepa

Lisebelisoa tsa Spur le pinion li tšehetsa mesebetsi ea mantlha ea mechini e mengata. Li fana ka ts'ebetso e phahameng, hangata e fihlangho fihla ho 98%, e fokotsang tahlehelo ea matla le ho boloka lisebelisoa li sebetsa hantle. Lits'ebetsong tsa Hydraulic Slewing, likere tsena li netefatsa ho potoloha ho nepahetseng le torque e tsitsitseng, leha e le tlas'a meroalo e boima. Ntlo e tiisitsoeng ea li-drive tsa Hydraulic Slewing e sireletsa likere ho tsoa lerōleng le metsing, ho li etsa hore li tšepahale libakeng tse thata.

Baetsi ba khetha lisebelisoa tsa spur le pinion bakeng sa ho tšoarella ha tsona le tlhokomelo e bonolo. Hangata li-drive tsa Hydraulic Slewing li sebelisa lisebelisoa tse matla joalo ka tšepe kapa tšepe e sa hloekang ho sebetsana le mesebetsi e thata. Li-drive tsena li ka sebetsa ka motors e le 'ngoe kapa tse peli tsa hydraulic, tse fanang ka maemo a bonolo bakeng sa mechini e fapaneng. Baenjiniere ba ananela Hydraulic Slewing bakeng sa bokhoni ba eona ba ho fana ka lebelo le potlakileng le torque e phahameng sebakeng se kopanetsoeng.

Mmaraka oa lefats'e oa mechini e sebelisang lisebelisoa tsa spur le pinion o moholo. Ka 2024,ho ile ha rekisoa li-gear tsa spur tse fetang limilione tse 15, le lekala la likoloi e le mosebelisi ea ka sehloohong.Theknoloji ea Hydraulic Slewinge tsoela pele ho hola ka bohlokoa kaha liindasteri li batla lisebelisoa tse sebetsang hantle le tse tšepahalang.

Li-gear tsa Spur li na le meno a otlolohilengle ho fetisa matla lipakeng tsa li-shafts tse bapileng.The pinion, kamehla e nyenyane gear, li-meshes tse nang le lisebelisoa tsa spur ho laola lebelo le torque.

- Spur le pinion gears li fanabokgabane bo phahameng, botshepehi, le ho nepahalamecheng e kang li-gearbox, liroboto le likoloi.

- Baenjiniere ba lebeletse tsoelo-pele e tsoelang pele kalisebelisoa tse bobebe le tlhahiso e tsoetseng pele, ho etsa bonnete ba hore lisebelisoa tsena li lula li le bohlokoa theknolojing e tlang.

LBH

Phapang e kholo ke efe lipakeng tsa spur gear le pinion gear?

Sesebelisoa sa spur se ka ba sa boholo leha e le bofe, ha gear ea pinion e lula e le lisebelisoa tse nyenyane ka bobeli. Hangata pinion e tsamaisa lisebelisoa tsa spur.

Hobaneng baenjiniere ba khetha lisebelisoa tsa spur le pinion bakeng sa mechini?

Baenjiniere ba khetha lisebelisoa tsa spur le pinion bakeng sa ts'ebetso ea bona e phahameng, moralo o bonolo, le phetisetso ea matla e tšepahalang. Lisebelisoa tsena li sebetsa hantle mecheng e mengata 'me li hloka tlhokomelo e fokolang.

Na likere tsa spur le pinion li ka sebetsana le meroalo e boima?

Ee. Li-gear tsa Spur le pinion, haholo-holo tse entsoeng ka thepa e matla joalo ka tšepe, li ka khonatšoara meroalo e boimaka lisebelisoa tse kang li-crane, li-excavator le li-gearbox tsa indasteri.

Nako ea poso: Jul-25-2025