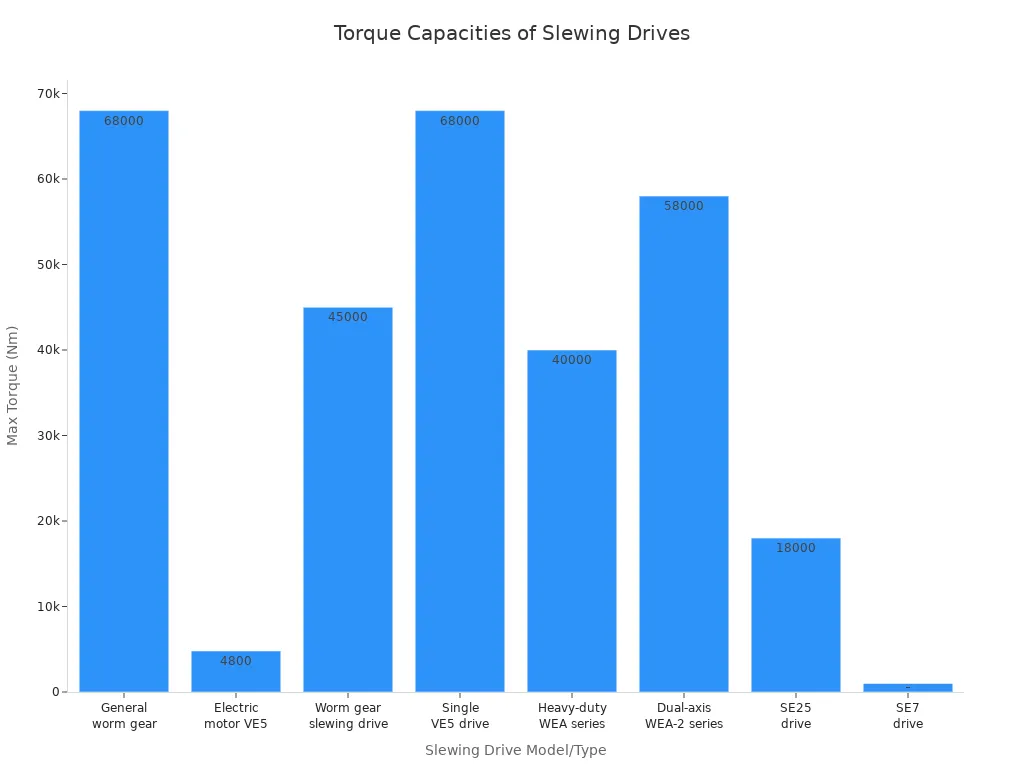

Slewing e fana ka motsamao o potolohang lipakeng tsa likarolo tsa mochini, e ts'ehetsa meroalo e meholo ka nepo. Lisebelisoa tse boima, joalo ka li-crane le li-turbine tsa moea, li itšetlehile ka li-bearings tse tsoetseng pele le likoloi. Thehydraulic slawing drivee netefatsa phetiso ea torque e tšepahalang.Bokhoni ba ho jara bo tloaelehileng bo fapana ka bongata:

| Slewing Drive Model/Mofuta | Torque Range (Nm) | Matla a Matla a Matla (kNm) | Lisebelisoa |

|---|---|---|---|

| Lisebelisoa tse akaretsang tsa ho bolaea liboko | 365 - 68,000 | Ho fihlela ho 190 | Li-cranes, li-turbine tsa moea, li-trackers tsa letsatsi |

| Motlakase oa koloi ea VE5 | 4,800 | N/A | Phetiso ea lisebelisoa tsa Worm |

| Koloi ea ho bolaea liboko | 2,500 - 45,000 | 190 | 360 ° swivel, mojaro o phahameng oa axial |

| Koloi e le 'ngoe ea VE5 | 500 - 68,000 | N/A | Ho latela letsatsi |

| Letoto le boima la WEA | 8,000 - 40,000 | N/A | Mechini ea temo |

| Letoto la li-axis tse peli tsa WEA-2 | 16 200; 19 440; 48 000; 58,000 | N/A | Litsela tse ngata, tse nang le moroalo o matla |

| Seboko sa "worm gear" SE25 | 18,000 | N/A | Li-cranes, li-excavators |

| Seboko sa "worm gear slewing drive" SE7 | 1,000 | N/A | Mojaro o phahameng, taolo e nepahetseng |

Lintlha tsa bohlokoa

- Mekhoa ea ho roala e etsa hore ho be le ho bilika ha bonolo, ka mokhoa o nepahetseng ka ho sebelisa li-bearings le li-rolling elements tse tšehetsangmeroalo e boimale ho fokotsa likhohlano.

- Kabo e nepahetseng ea mojaro le taolo ea torque ho li-drive tse bolaeang li netefatsa motsamao o tsitsitseng le o nepahetseng, o bohlokoa bakeng sa mechini e boima joalo ka li-crane le li-turbine tsa moea.

- Tlhokomelo ea kamehla, ho kenyeletsoa ho tlotsa le ho hlahloba ka nako e loketseng, ho lelefatsa bophelo ba lisebelisoa tsa ho bolaea le ho boloka lisebelisoa li sebetsa ka mokhoa o sireletsehileng le ka katleho.

Likarolo Tse Ka sehloohong tsa Mekhoa ea ho Slewing

Mehele ea ho Slewing le Bearings

Li-ringing le li-bearings li theha mokokotlo oa mekhoa ea ho bolaea. Likarolo tsena tse kholo, tse chitja li tšehetsa boima bohle ba sebopeho se pota-potileng 'me li nolofalletsa motsamao o boreleli, o laoloang. Rele ea ho hlaba hangata e na le masale a ka hare le a ka ntle, 'me ho na le lintho tse bilikang pakeng tsa tsona. Li-bearings li sebetsana le meroalo ea axial, radial, le ea motsotsoana, ho netefatsa botsitso le ts'ebetso e tšepahalang. Tafole e ka tlase e akaretsa lintlha tsalikarolo tse kholo le mesebetsi ea tsona:

| Karolo | Mosebetsi |

|---|---|

| Ring ea ho Slewing | E tšehetsa meroalo e boima mme e nolofalletsa ho potoloha ha bonolo. |

| Bearings | Laola axial, radial, le meroalo ea nakoana bakeng sa botsitso. |

| Mokhoa oa ho khanna | E fana ka torque bakeng sa ho potoloha, hangata ka li-motors tsa motlakase kapa tsa hydraulic. |

Rolling Elements

Lintho tse bilikang, tse kang libolo kapa li-roller, li fokotsa khohlano le ho roala ka har'a selikalikoe sa ho bolaela. Tlhophiso le mofuta oa tsona li ama ka ho toba katleho le ho tšoarella.Li-bearings tsa bolo ea lintlha tse 'neaba meroalo lintlheng tse 'nè, ho eketsa ho ikamahanya le maemo. Li-rolara tsa sefapano, tse nang le li-roller tse behiloeng ka mahlakoreng a nepahetseng, li fana ka kabo e phahameng ea mojaro le ho tiea. Lirolara tse nang le mela e meraro li fana ka moroalo o phahameng ka ho fetisisa, o li etsa tse loketseng lits'ebetso tse boima. Khetho ea "rolling element" e ama ts'ebetso ea mochini le nako ea bophelo.

Li-Gears le Drive Systems

Gears letsamaiso ea likoloifetisa matla ho tloha ho enjene ho isa lesale la ho bolaela. Mekhoa e mengata ea ho bolaea e sebelisoatlhophiso ea lisebelisoa tsa liboko, moo molamu oa sebōkō o tsamaisang thepa e pota-potileng. Setupo sena se fokotsa lebelo mme se eketsa torque, e bohlokoa bakeng sa mochini o boima. Meetso ea sejoale-joale hangata e na le theknoloji ea seboko sa hourglass, e ntlafatsang ho kenella ha meno le ho tšoarella. Sistimi ea li-Dual-axis le li-drive tse peli li eketsa matla le taolo.

Litiiso le Lubrication

Litiiso le lubrication li sireletsa likarolo tsa ka hare le ho netefatsa ts'ebetso ea nako e telele. Litiiso tsa boleng bo phahameng li thibela litšila ho kena ka har'a bere.Lubrication e nepahetsenge fokotsa khohlano, e thibela ho kopana ha tšepe le tšepe, 'me e qhala mocheso. Tlhokomelo ea kamehla letheknoloji e tsoetseng pele ea ho tlotsa, joalo kasetlolo se tiileng, lelefatsa bophelo ba ho jara le ho tšepahala. Lisebelisoa tse hlokometsoeng hantle tsa lubrication li boetse li fokotsa lerata le ho thothomela, tse tšehetsang ts'ebetso e bonolo.

Mokhoa oa ho Slawing o Sebetsa Joang

Tšebelisano ea Likarolo bakeng sa Rotation

Mekhoa ea ho roala e finyella ho potoloha ha bonolo ka ketso e hokahaneng ea likarolo tse 'maloa tsa bohlokoa. Tshebetso e etsahala ka tatellano e nepahetseng:

- TheBearing e lutse pakeng tsa likarolo tse peli tse kholo tsa mochini, joalo ka setsi sa crane le sebopeho sa eona se pota-potileng.

- Matla a ka ntle, ho kenyelletsa le boima ba lisebelisoa le meroalo ea ts'ebetso, e sebetsa ho beng.

- Lintho tse bilikang - libolo kapa li-roller - li tsamaea pakeng tsa mehele e ka hare le e ka ntle ea bere.

- Lintho tsena tse bilikang li tsamaisa mojaro o kentsoeng ho pholletsa le libaka tsa bona tsa ho kopana le litselana tse entsoeng ka ho khetheha.

- Litsela tsa mabelo, ka li-grooves tsa tsona tse ntlafalitsoeng, li fokotsa khatello ea maikutlo le ho netefatsa ho arolelana mojaro.

- Likarolo tse peli tsa rolling le geometry ea raceway li hanana le deformation, leha e le tlas'a meroalo e boima.

- Ho hanyetsa hona ho lumella ho potoloha ha bonolo, ho fokolang pakeng tsa likarolo tse hokahaneng.

- Tlhophiso e nepahetseng ea lintho tse bilikang le geometry ea litsela tsa mabelo li thusa ho laola motsamao o nepahetseng.

- Ha mochini o ntse o potoloha, ho beleha ho tsoela pele ho arolelana meroalo e fetohang ho boloka botsitso.

- Lisebelisoa tse tsoetseng pele le mekhoa ea boenjiniere e eketsa bophelo ba tšebeletso ea bearing le ho netefatsa ts'ebetso e ka tšeptjoang tlas'a maemo a sa tšoaneng.

Hlokomela: Ho apara le ho khathala ho emela mekhoa e tloaelehileng ea ho hlōlehaka dibering tsa ho hlaba. Mathata ana hangata a hlaha ka lebaka la meroalo ea libaesekele, likhohlano, mathata a mafura, kapa kopano e sa lokelang. Mathata a mang a ka bang teng a kenyelletsa ho robeha, ho bola le ho senyeha. Ho hlahloba le ho hlokomela khafetsa ho thusa ho thibela liphoso tsena le ho netefatsa ts'ebetso e bolokehileng, e tšepahalang.

Kabo ea Mojaro le Tšehetso

Li-bearings tsa Slewing li tlameha ho sebetsana le maemo a boima a boima nakong ea ts'ebetso. Meroalo ena e kenyelletsa:

- Meroalo ea Axial:Matla a sebetsang ka mokhoa o lumellanang le axis ea ho potoloha, hangata a bakoang ke boima ba thepa kapa tšusumetso ea kantle.

- Radial loads:Matla a sebetsang a bapile le axis, joalo ka a bakoang ke moea kapa litlamorao tsa centrifugal.

- Meroalo ea nakoana:Motsoako oa matla a axial le radial, hangata a hlahisoang ke motsamao le boima ba mochini.

Kabo ea mojaro ho pholletsa le bering ha se hangata e ts'oanang. Ho kobeha ha tsela ea mabelo le palo ea lintho tse bilikang li susumetsa tsela eo meroalo e hasanang ka eona. Baenjiniere ba ntlafatsa kabo ea mojaro ka ho fetola palo le boholo ba lintho tse bilikang, sebaka sa ho ikopanya le boemo ba mabelo.

Mekhoa e mengata ea boenjiniere e thusa ho boloka ts'ehetso ea mojaro:

- Lubrication e nepahetseng e fokotsa likhohlano le ho roala, ho tšehetsa kabo ea mojaro o tšoanang.

- Ho khetha mafura a nepahetseng-e thehiloeng ho lithium, calcium-based, kapa polyurea-e netefatsa ts'ebetso e nepahetseng bakeng sa maemo a itseng a ts'ebetso.

- Li-additives tse kang molybdenum disulfide (MoS₂) li ntlafatsa bokhoni ba ho jara meroalo le thepa e khahlanong le ho apara.

- Ho ikamahanya le linako tse khothalelitsoeng tsa ho tlotsa le bongata ho thibela ho roala pele ho nako le khatello ea maikutlo e sa lekanang.

- Geometry ea lintlha tse 'nèlumella mola o le mong oa libolo ho tšehetsaaxial, radial, le moroalo oa motsotsoanaka nako e le nngwe.

- Ntlafatso ea tumello ea ka hare e amohela ho se lumellane le katoloso ea mocheso, ho boloka ho nepahala ha potoloho.

- Ho etsa ka nepo, ho kenyeletsoa mochini oa CNC le ho thatafala ha induction, ho hlahisa litselana tsa boleng bo holimo tse mamellang meroalo e matla.

- Ho satalla ho hoholo le moralo o kopaneng o fokotsa boima ba sistimi le ho ts'ehetsa meroalo ea eccentric kapa offset ka katleho.

Keletso:Meralo e nolofalitsoeng ea ho jara e nang le likarolo tse fokolang ha e nolofatse kopano le tlhokomelo feela empa hape e kenya letsoho ts'ebetsong e tsitsitseng esita le kabong ea mojaro.

Phetiso ea Torque le Taolo

Phetiso ea torque e bohareng ba ts'ebetso ea mochini o bolaeang. Theli-gear li fetisetsa torqueho tloha mohloling oa matla oa mochine-ebang ke motlakase kapa motlakase oa haeteroliki-ho ea mohahong o potolohang. Ts'ebetso ena e nolofalletsa ho potoloha ho pota-pota axis e otlolohileng, e lumellang hore meroalo e boima e behoe ka nepo.

Likarolo tsa bohlokoa tsa phetiso le taolo ea torque li kenyelletsa:

- Themotlakase o hlahisa torque, e fetang ka mokhoa oa ho fetisa. Sistimi ena e ka sebelisa li-pinion, likere tsa liboko, kapa mefuta e meng ea lisebelisoa.

- The slewing bear e amohela torque e fetisitsoeng, e tšehetsang axial, radial, le meroalo ea motsotso ha e ntse e nolofalletsa ho potoloha ho laoloang.

- Liphatlalatso tsa lisebelisoa tsa Worm li fana ka tšobotsi ea ho itšeha, e thusang ho tšoara meroalo ka mokhoa o sireletsehileng le ho lumella taolo e nepahetseng ea ho potoloha.

- Kopano ea ho bolaea e kenyelletsa tsamaiso ea matlo le ho tiisa ho sireletsa likarolo tsa ka hare le ho boloka ts'ebetso e tsitsitseng.

- Likarolo tsohle li sebetsa 'moho ho fana ka motsamao o nepahetseng, o boreleli oa ho potoloha le ho boloka mojaro o tsitsitse nakong ea ts'ebetso.

| Paramethara | Boleng/Tlhaloso |

|---|---|

| Mofuta oa Drive oa Slewing | Spur gear slewing drive |

| Karolelano ea Gear | 9:1 |

| Rated Output Torque | ~37 kN·m(mohlala o tloaelehileng oa mosebetsi o boima) |

| Potoloho Center Diameter | 955 limilimithara |

| Kakaretso ea Bophahamo e nang le Adapter | 180 limilimithara |

| Gear Backlash | ≤ 0.40 limilimithara |

| Kopo | Thepa e boima e nang le nako e kholo ea ho sekama le meroalo e boima |

| Moqapi oa Fetola | Li-drive tse kholoanyane li fumaneha ka bophara ho fihla ho 2300 mm le torque e phahameng |

Mekhoa ea sejoale-joale ea ho bolaea e kopanya boenjiniere bo matla, lisebelisoa tse tsoetseng pele, le tlhahiso e nepahetseng ho fana ka phetisetso le taolo ea torque e tšepahalang. Sena se tiisa hore mechine e boima e ka sebetsa ka mokhoa o sireletsehileng le ka katleho, esita le tlas'a maemo a boima.

Mefuta le Menahano e Sebetsang

Hydraulic Slewing

Sistimi ea Hydraulic Slewing e sebelisa mokelikeli o hatelletsoeng ho hlahisa torque e phahameng le taolo e boreleli, e lekanang. Litsamaiso tsena li ipabola lits'ebetsong tse boima, joalo ka li-cranes le li-excavator, moo ts'ebetso e tsoelang pele tlas'a meroalo e meholo e hlokahalang.Hydraulic Slewinge fana ka ts'ebetso e phahameng ea mochini le ts'ebetso e tšepahalang libakeng tse thata. Basebelisi ba rua molemo ka ho sisinyeha ho nepahetseng ka lebelo le tlase, e leng ntho ea bohlokoa bakeng sa ho phahamisa le ho beha lintho tse boima.Sistimi ea ho Slewing ea Hydraulice hloka ho kopanngoa le lipompo tsa hydraulic le tsamaiso ea metsi, ho etsa hore ho kenya le ho boloka ho be thata ho feta mekhoa e meng ea motlakase. Leha ho le joalo, li fana ka matla a holimo a ho hula 'me li ka sebetsa ntle le ho chesa haholo nakong ea tšebeliso e telele. TheTs'ebetso ea Hydraulic Slewing e ntlafala le ho feta lits'ebetsong tse nyalisitsoeng, e fokotsang matla a holimo le tšebeliso ea matla.

Mefuta e meng ea mekhoa ea ho robala

Mechini ea sejoale-joale e sebelisa mefuta e mengata ea mochini oa ho hlaba, o mong le o mong o na le likarolo tse ikhethang.Li-drive tsa gear tsa Worm li fana ka phokotso e phahameng ea lisebelisoa sebakeng se kopanengle ho fana ka bokhoni ba ho itšireletsa, e leng se matlafatsang polokeho. Li-drive tsa li-gear tsa Spur li sebelisa li-shafts tse bapileng le meno a otlolohileng, li li etsa hore li tšoanelehe bakeng sa literene tse bonolo tsa gear.Mechine ea ho hlaba ka motlakase e kopanya likere tsa liboko le li-ring bearings, ho fana ka potoloho e nepahetseng, e phahameng ea torque le libaka tse sireletsehileng tsa ho tšoara.Tafole e ka tlase e akaretsa mefuta e tloaelehileng ea li-slewing le lisebelisoa tsa eona:

| Mofuta oa ho Slewing Bearing | Sebopeho sa Sebopeho | Lisebelisoa tse Tloaelehileng Mechineng ea Kajeno |

|---|---|---|

| Lintlha tse 'nè Kopana Ball Slewing Bearing | Sebopeho se bonolo, se tšehetsa matla a mabeli a axial le radial, matla a mang a ho phethola motsotsoana | Li-cranes tse nyenyane, lisebelisoa tsa ho tšoara thepa |

| Bolo ea methalo e 'meli ea bophara bo fapaneng | Mela e 'meli ea libolo, bokhoni bo ntlafalitsoeng ba mojaro le bophelo ba ts'ebeletso | Mechini ea boema-kepe e mahareng, li-cranes tsa stacking |

| Crossed Cylindrical Roller | Nako e phahameng ea ho phethoha le matla a axial a matla, ho nepahala ho phahameng ho potoloha | Li-cranes tse kholo tsa boema-kepe, li-cranes tsa borokho |

| Roller ea Cylindrical ea mela e meraro | Sebaka se seholo sa ho ikopanya, se ts'ehetsa linako tse kholo tsa axial, radial, le ho phethola | Mechini e kholo haholo, e boima haholo |

Tlhokomelo le Tlhokomelo

Tlhokomelo e nepahetseng e tiisa nako e telele le ho tšepahala ha mekhoa ea ho bolaea.Basebelisi ba lokela ho hlahloba liboutu pele ho ts'ebetso ka 'ngoe le ka mor'a lihora tse 100 tsa pele tsa ho sebetsa, ebe ka lihora tse 300, le lihora tse ling le tse ling tse 500 ka mor'a moo.Nako ea ho lubrication e tloha ho lihora tse ling le tse ling tse 200 ho isa ho tse 500, ho itšetlehile ka mojaro le tikoloho. Maemong a thata, joalo ka mongobo o phahameng kapa lerōle, lipotoloho tsa lubrication li lokela ho khutsufatsoa. Ho hlahlojoa khafetsa ho thusa ho lemoha ho tsofala, tšenyo, kapa tšoaetso kapele. Ho hloekisa, ho tlotsa ka mokhoa o nepahetseng, le ho khutlisa likarolo tse tsofetseng ka nako ho thibela ho hloekisoa ho feteletseng, ho lutla ha oli le ho futhumala ho feteletseng.

Likopo tse Tloaelehileng

Mekhoa ea ho roala e phetha karolo ea bohlokoa liindastering tse ngata.Mechini ea kaho le ea indasteri e itšetlehile ka tsona bakeng sa ho potoloha ha 360-degree le tšehetso ea meroalo e boima. Lisebelisoa tse tloaelehileng li kenyelletsa:

- Li-excavator le li-cranes tsa ho phahamisa le ho sebetsana le thepa

- Mechini ea meru le lifereko

- Lisebelisoa tsa merafo le literaka tsa litšepe

- Likoloi tse phahameng le liroboto tsa indasteri

Mechini ena e boetse e hlaha makaleng a leoatle, matla a ka nchafatsoang, a sefofane le a li-automation, a tšehetsang motsamao o nepahetseng le botsitso.

Mechini ea ho reketla e thusa ho potoloha ka mokhoa o nepahetseng, o boima ho pholletsa le liindasteri, ho tloha ho li-crane ho ea ho li-turbine tsa moea. Meetso ea bona e tsoetseng pele, joalo kamela e meraro ea rolara le libere tsa sefapano, tšehetsa meroalo e rarahaneng le ho netefatsa ts'ebetso e tšepahalang.Tlhokomelo ea kamehla, ho kenyelletsa le litsamaiso tsa Hydraulic Slewing, li eketsa nako ea bophelo ba lisebelisoa le polokeho ea ts'ebetso. Litlhahiso tse tsoelang pele li tsoela pele ho khanna katleho le ho nepahala.

LBH

Mosebetsi o ka sehloohong oa koloi ea ho bolaea ke ofe?

A ho khannae nolofalletsa motsamao oa ho potoloha o laoloang lipakeng tsa likarolo tse peli tsa mochini. E ts'ehetsa meroalo e boima mme e netefatsa boemo bo nepahetseng ho lisebelisoa tsa indasteri.

Basebelisi ba lokela ho tlotsa li-bearings hangata hakae?

Basebelisi ba lokela ho tlotsa li-bearings tsa ho bolaela lihora tse ling le tse ling tse 200 ho isa ho tse 500. Tikoloho e thata e ka hloka ho tlotsoa khafetsa ho boloka ts'ebetso e nepahetseng.

Na lisebelisoa tsa ho lla li khona ho sebetsana le meroalo ea axial le radial?

Ee. Mekhoa ea ho roala e tšehetsa meroalo ea axial, radial, le ea motsotsoana. Moqapi oa bona o aba matla ana ka katleho, ho netefatsa botsitso le bophelo bo bolelele ba tšebeletso.

Nako ea poso: Jul-25-2025