Lub spur iav nta cov hniav ncaj thiab rotates ntawm ib qho kev sib luag. Ib lub iav pinion, feem ntau yog cov iav me me hauv ib khub, meshes nrog cov iav spur kom xa cov lus tsa suab. Ua ke, spur thiab pinion gears zoo hloov lub zog hauv ntau qhov kev lag luam, suav nrog tsheb, aerospace, thiab Hydraulic Slewing daim ntawv thov.

Ntsiab Cai

- Spur thiab pinion gears ua haujlwm ua ke kom hloov lub zog zoo ntawm cov khoom sib txuas, nrog cov pinion feem ntau yog cov tsav tsheb me me.

- Cov iav no muaj ntau heevkev ua haujlwm siab, feem ntau siab dua 98%, ua rau lawv zoo tagnrho rau cov tshuab uas xav tau kev tswj xyuas cov lus tsa suab kom ntseeg tau thiab meej.

- Spur thiab pinion gears yog dav siv nyob rau hauv ntau lub lag luam, xws li tsheb, aerospace, thiabhydraulic slewing, vim lawv durability thiab yooj yim txij nkawm.

Yuav Ua Li Cas Spur thiab Pinion Gears Ua Haujlwm

Basic Mechanics

Spur thiab pinion gears ua haujlwm ntawm cov ntsiab lus yooj yim tab sis meej. Cov iav no xa cov lus tsa suab ntawm qhov sib npaug ntawm cov shafts, tswj qhov nrawm nrawm. Lub involute hniav profile, cov duab nkhaus, ua kom cov meshing du thiab khov kho ceev thaum lub sijhawm ua haujlwm.

- Covsuab voj voogyog ib lub voj voog kev xav uas dhau los ntawm qhov chaw uas cov hniav ntawm ob lub zog koom nrog. Qhov taw tes no, hu ua pitch point, yog qhov chaw uas lub zog hloov pauv tau zoo tshaj plaws.

- Conjugate kev txiav txim txhais tau hais tias raws li ib tug iav iav pushes lwm tus, cov hniav uas tau tsav nyob rau hauv zoo meej kev faib ua feem, ua kom tus ceev piv.

- Cov iav piv yog nyob ntawm tus naj npawb ntawm cov hniav los yog txoj kab uas hla ntawm lub suab voj voog. Ib lub iav loj ua ke nrog lub pinion me me ua kom lub zog loj dua tab sis txo qhov nrawm.

- Cov ntsiab lus tseem ceeb suav nrog:

- Module(metric ntsuas ntawm cov hniav loj)

- Diameter suab(Imperial ntsuas)

- Lub kaum sab xis(feem ntau yog 20 °)

- Sib cuag piv(nruab nrab tus naj npawb ntawm cov hniav sib cuag)

Nco tseg:Qhov sib txuas sib txuas pab sib faib cov khoom nruab nrab ntawm cov hniav, ua rau lub iav kaw kom muaj zog thiab smoother.

Kev xaiv cov khoom siv ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm ntawm iav. Hlau, bronze, thiab thermoplastics zoo li nylon lossis acetal yog cov kev xaiv ntau. Hlau muaj zog thiab kav ntev, thaum yas txo suab nrov thiab tiv thaiv corrosion. Bronze thiab stainless hlau ua tau zoo nyob rau hauv ntub los yog hnyav ib puag ncig. Engineers feem ntau sivKev kho cua sov xws li carburizing lossis induction hardeningtxhawm rau ua kom lub ntsej muag hardness thiab txuas ntxiv lub neej iav.

Ib tug raug spur thiab pinion iav teeb siv lub pinion raws li lub iav tsav. Nws cov hniav mesh nrog cov spur iav,hloov txav thiab torque. Cov hniav ncaj ntawm spur iav tso cai rau kev hloov hluav taws xob zoo ntawm cov khoom sib txuas.

Motion thiab Fais fab Hloov

Kev sib cuam tshuam ntawm spur thiab pinion iav hniav yog qhov tseeb thiab ua tau zoo. Cov hniav mesh ntawm lawv lub suab voj voog, qhov twg qhov kev hloov ntawm kev sib hloov thiab lub zog torque tshwm sim. Raws li tus pinion tig, nws cov hniav thawb tawm tsam cov spur iav cov hniav, ua rau cov spur iav tig. Qhov chaw tiv tauj txav raws tuskab kev ua, ib txoj kab kev xav uas coj lub zog sib kis ntawm cov iav.

- Cov iav hniav koom nrog lub suab voj voog, hloov cov lus tsa suab thiab lub zog.

- Qhov chaw sib tiv tauj mus raws txoj kab ntawm kev ua, kom ntseeg tau tias kev sib hloov quab yuam.

- Involute hniav profiles txo qhov cuam tshuam loads thiab tso cai rau kev sib koom ua ke.

- Geometric yam xws li lub suab lub voj voog txoj kab uas hla, lub kaum sab xis siab, thiab backlash cuam tshuam li cas ntawm cov iav mesh.

- Backlash, qhov sib txawv me me ntawm cov hniav, tiv thaiv jamming thiab tso cai rau thermal expansion.

- Lub meshing lub kaum sab xis cuam tshuam kev sib txhuam thiab suab nrov thaum ua haujlwm.

- Cov yam ntxwv no ua rau lub pinion tsav lub spur iav nrog kev ua haujlwm siab thiab kev ntseeg siab.

Lub iav piv, txhais raws li tus naj npawb ntawm cov hniav ntawm cov iav tsav tau muab faib los ntawm tus lej ntawm cov iav tsav, ncaj qha cuam tshuam rau kev ceev thiab lub zog. Piv txwv li, a2: 1 iav ratiotxhais tau hais tias lub iav tsav tig ntawm ib nrab ntawm qhov ceev ntawm lub pinion tab sis xa ob zaug lub zog. Qhov kev sib raug zoo no tso cai rau cov engineers los tsim cov tshuab iav uas phim cov kev xav tau tshwj xeeb.

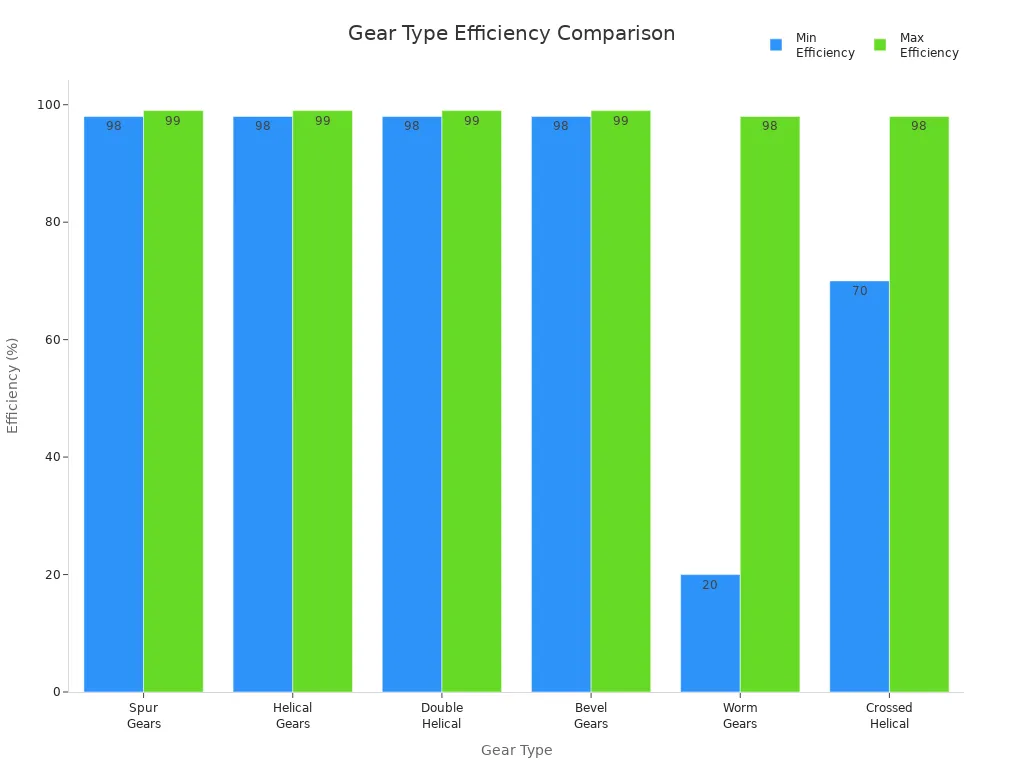

| Hom iav | Efficiency Range | Cov ntsiab lus tseem ceeb ntawm kev ua tau zoo thiab poob |

|---|---|---|

| Spur Gears | 98-99% | High efficiency; tsawg kawg poob los ntawm cov hniav txhuam hniav thiab lubrication churning |

| Helical iav | 98-99% | Me ntsis qis dua spur vim axial thrust thiab zawv zawg ua |

| Muab ob npaug rau Helical | 98-99% | Piv rau spur thiab helical iav |

| Bevel Gears | 98-99% | High efficiency tab sis qis dua spur vim zawv zawg ua |

| Worm Gears | 20-98% | Qhov ua tau zoo qis dua, nyob ntawm cov iav piv thiab cov xwm txheej |

| Hla Helical | 70-98% | Kev ua haujlwm qis dua vim yog zawv zawg thiab cov hniav sib txuas |

Spur thiab pinion iav sawv tawm rau lawv cov kev ua haujlwm siab, feem ntau ncav cuag 98-99%. Qhov no ua rau lawv zoo tagnrho rau cov ntawv thov uas tsawg kawg lub zog poob yog qhov tseem ceeb. Txawm li cas los xij, spur gears nyiamtsim suab nrov ntau dua li cov iav helicalvim hais tias lawv cov hniav koom dheev, tso lub zog sai sai thiab ua rau muaj kev vibration. Helical iav, nrog lawv cov hniav, ua haujlwm ntsiag to tab sis muaj ntau txoj hauv kev tsim khoom.

Kev tu vaj tse yog qhov tseem ceeb rau kev ua haujlwm ruaj khov. Cov teeb meem muaj xws lihnav, misalignment, thiab tsis txaus lubrication. Kev tshuaj xyuas tsis tu ncua thiab lubrication kom zoo pab tiv thaiv cov teeb meem xws li pitting, spalling, thiab abrasive hnav. Xaiv cov ntaub ntawv raug thiab tswj kom raug kev sib raug zoo txuas ntxiv lub neej ntawm spur thiab pinion gears, kom ntseeg tau tias lub zog hloov pauv tau zoo hauv ntau lub tshuab.

Cov yam ntxwv tseem ceeb thiab qhov sib txawv

Spur Gear Design

Spur iav sawv tawm rau lawvncaj hniav, uas khiav parallel mus rau lub iav axis. Qhov kev tsim no tso cai rau kev sib cuag ncaj qha ntawm cov hniav, ua rauhigh efficiency - feem ntau siab dua 98%. Spur gears xa cov lus tsa suab ntawm qhov sib npaug ntawm cov ncej thiab muaj cov duab cylindrical yooj yim. Feem ntau cov spur iav yog sab nraud, nrog cov hniav nyob rau sab nraud, ua rau cov iav tsav tig mus rau qhov sib txawv. Internal spur gears, nrog cov hniav nyob rau hauv, tso cai rau kom sib ze ncej sib nrug thiab siab dua torque tab sis yuav tsum tau ntau complex manufacturing.

| Feature | Spur Gears | Lwm yam Iav Hom (Cov ntsiab lus) |

|---|---|---|

| Hniav Tsim | Ncaj cov hniav sib npaug rau iav axis | Helical: angled hniav; Bevel: conical; worm: ntsia hlau zoo li; Planetary: ntau lub ntiaj teb iav |

| Ncej Orientation | Parallel shafts | Helical: parallel; Bevel: sib tshuam; Kab mob: tsis sib luag; Planetary: parallel/coaxial |

| Kev ua tau zoo | Siab (98% lossis ntau dua) | Helical: me ntsis qis; Bevel: nruab nrab; Kab: qis; Planetary: siab |

| Lub suab nrov | Tsis nrov ntawm kev kub ceev | Helical: ntsiag to; Bevel: nruab nrab; Kab: nyob ntsiag to; Planetary: nruab nrab |

| Complexity & Nqi | Yooj yim, tus nqi qis | Helical: ntau dua; Bevel: nruab nrab; Kab mob: complex; Planetary: heev complex |

Tus naj npawb ntawm cov hniav ntawm lub spur iav cuam tshuam rau iav piv, smoothness, thiab load faib. Engineers feem ntau xaivyam tsawg kawg yog 18 hniavrau cov qauv tsim kom tsis txhob undercutting thiab ua kom ntseeg tau kev ua haujlwm.

Pinion iav yam ntxwv

Pinion iav feem ntau yog cov iav me me hauv ib khub. Lawv txoj hauj lwm nyob rau hauv lub iav tsheb ciav hlau txiav txim siab qhov system cov cuab yeej kom zoo dua thiab quab yuam cov zis. Thaum siv nyob rau hauv khib-thiab-pinion systems, lubpinion lub torque thiab ceev ncaj qha cuam tshuam lub zog thiab txav ntawm lub khib. Nyob rau hauv planetary iav tsheb ciav hlau,saj zawg zog mounting ntawm pinion iav pab faib loads tusyees, txhim kho durability thiab txo kev ntxhov siab. Kev nce qib hauv cov ntaub ntawv, xws licarbon fiber reinforced polymers, muaj zog pinion iav durability, cia lawv ua tau zoo txawm nyob rau hauv tej yam kev mob nyuaj.

Tswv yim: Xaiv cov khoom tsim nyog thiab suav cov hniav rau lub pinion iav tuaj yeem txuas nws txoj sia thiab txhim kho kev ua haujlwm.

Spur iav vs. Pinion iav

Spur gears thiab pinion gears qhia cov txheej txheem tsim khoom zoo sib xws, ob qho tib si tau txais txiaj ntsig los ntawmyooj yim thiab raug nqi ntau lawm. Spur gears ua tus tsav tsheb tseem ceeb lossis lub zog tsav, thaum lub zog pinion feem ntau ua raws li cov tswv yim lossis cov zis, tshwj xeeb tshaj yog nyob rau hauv khib-thiab-pinion lossis planetary systems. Spur gears feem ntau tswj lub zog xa hluav taws xob, thaum lub zog pinion tuaj yeem hloov pauv cov lus tsa suab mus rau txoj kab txav. Ob hom tam sim no siv txoj kev tsim khoom lag luam, xws lize-net puab forgingthiabcov khoom siv rov ua dua tshiab, kom txo kev cuam tshuam ib puag ncig. Lawv qhov sib txawv ntawm qhov loj me, kev ua haujlwm, thiab daim ntawv thov ua rau txhua qhov tseem ceeb hauv cov tshuab tshuab.

Kev siv tswv yim thiab Hydraulic Slewing

Kev siv txhua hnub thiab piv txwv

Spur thiab pinion iav tshwm nyob rau hauv ntau yam khoom txhua hnubthiab industrial machinery. Cov neeg pom cov iav no hauv lub tsheb sib kis, lub kauj tsheb, thiab txawm tias tsheb kauj vab. Hauv tsev, lub tshuab ntxhua khaub ncaws, tshuab ntxhua khaub ncaws, thiab cov moos cia siab rau cov spur iav kom ua haujlwm zoo. Pinion gears ua lub luag haujlwm tseem ceeb hauvkhib thiab pinion steering, pab cov neeg tsav tsheb tswj cov tsheb nrog qhov tseeb. Factories siv cov iav no hauv cov siv conveyor, twj, thiab ntim tshuab kom txav cov khoom kom zoo.

| Kev lag luam / Machinery Hom | Kev siv tswv yim ntawm Spur thiab Pinion Gears |

|---|---|

| Automotive | Kev txo cov iav, cov kauj tsheb, txoj kev chais |

| Muaj Machinery | Gearboxes, conveyors, twj, compressors, tshuab cuab yeej |

| Aerospace | Davhlau tswj, dav hlau cav, tsaws iav |

| Lub zog tiam | Cua turbines, chaw nres tsheb hydroelectric |

| Kev Lag Luam Textile | Spinning, weaving, dyeing machinery |

| Cov khoom siv | Cov moos, tshuab luam ntawv, cov cuab yeej hluav taws xob |

| Cov khoom siv hauv tsev | Cov tshuab ntxhua khaub ncaws, tshuab ntxhua khaub ncaws, tshuab ziab khaub ncaws |

| Robotics thiab Automation | CNC tshuab, servo mechanisms |

| Tsawg-Speed Vehicles & Khoom siv | Tsheb kauj vab, kilns, pob zeb |

| Mechanical Actuators | Rack thiab pinion systems |

Hydraulic Slewing systemssiv spur thiab pinion gears tig cov khoom hnyav xws li cranes thiab excavators. Cov tshuab no hloov hydraulic lub cev muaj zog rau hauv kev tswj kev txav, ua kom yooj yim nqa thiab tig cov khoom loj. Covcompact tsim of Hydraulic Slewing tsavtso cai rauplug-and-play installation, txuag lub sijhawm thaum sib dhos.

Qhov tseem ceeb hauv tshuab thiab khoom siv

Spur thiab pinion gears txhawb cov haujlwm tseem ceeb ntawm ntau lub tshuab. Lawv muab kev ua haujlwm siab, feem ntau ncav cuagmus txog 98%, uas txo lub zog poob thiab ua kom cov cuab yeej ua haujlwm zoo. Nyob rau hauv Hydraulic Slewing daim ntaub ntawv, cov iav no xyuas meej meej kev sib hloov thiab ruaj khov torque, txawm nyob rau hauv hnyav loads. Lub tsev kaw ntom nti ntawm Hydraulic Slewing drives tiv thaiv cov iav los ntawm cov plua plav thiab dej, ua rau lawv ntseeg tau hauv qhov chaw hnyav.

Cov neeg tsim khoom xaiv spur thiab pinion iav rau lawv cov kav ntev thiab kev saib xyuas yooj yim. Hydraulic Slewing drives feem ntau siv cov ntaub ntawv muaj zog xws li steel lossis stainless hlau los tuav cov haujlwm nyuaj. Cov tsav no tuaj yeem ua haujlwm nrog ib lossis ob lub tshuab hydraulic, muab kev yooj yim rau cov tshuab sib txawv. Cov kws tsim khoom muaj nuj nqis Hydraulic Slewing rau nws lub peev xwm xa cov nrawm nrawm thiab siab torque hauv qhov chaw compact.

Kev lag luam thoob ntiaj teb rau cov tshuab siv spur thiab pinion iav yog qhov loj. Hauv xyoo 2024,Ntau tshaj 15 lab spur iav units tau muag, nrog rau automotive sector raws li tus neeg siv loj.Hydraulic Slewing technologytxuas ntxiv loj hlob hauv qhov tseem ceeb raws li kev lag luam xav tau cov cuab yeej siv tau zoo thiab txhim khu kev qha.

Spur iav muaj cov hniav ncajthiab hloov lub zog ntawm cov ncej sib npaug.Lub pinion, ib txwm lub me iav, meshes nrog spur iav los tswj kev ceev thiab torque.

- Spur thiab pinion gears xahigh efficiency, kev cia siab, thiab precisionhauv cov tshuab xws li gearboxes, robotics, thiab tsheb.

- Engineers cia siab tias txuas ntxiv innovation nrogCov khoom siv hnyav thiab kev tsim khoom siab heev, kom ntseeg tau tias cov iav no tseem ceeb heev hauv kev siv tshuab yav tom ntej.

FAQ

Dab tsi yog qhov txawv ntawm lub spur iav thiab lub pinion iav?

Lub spur iav tuaj yeem yog qhov loj me, thaum lub iav pinion ib txwm yog cov iav me me hauv khub. Lub pinion feem ntau tsav lub spur iav.

Vim li cas cov engineers xaiv spur thiab pinion gears rau cov cav tov?

Engineers xaiv spur thiab pinion gears rau lawv cov high efficiency, yooj yim tsim, thiab txhim khu kev qha fais fab hloov. Cov iav no ua haujlwm zoo hauv ntau lub tshuab thiab xav tau kev saib xyuas tsawg.

Puas tuaj yeem spur thiab pinion gears tuav cov khoom hnyav?

Yog lawm. Spur thiab pinion gears, tshwj xeeb tshaj yog cov uas ua los ntawm cov ntaub ntawv muaj zog xws li steel, tuaj yeemtuav hnyav loadsnyob rau hauv cov khoom siv xws li cranes, excavators, thiab industrial gearboxes.

Post lub sij hawm: Lub Xya hli ntuj-25-2025