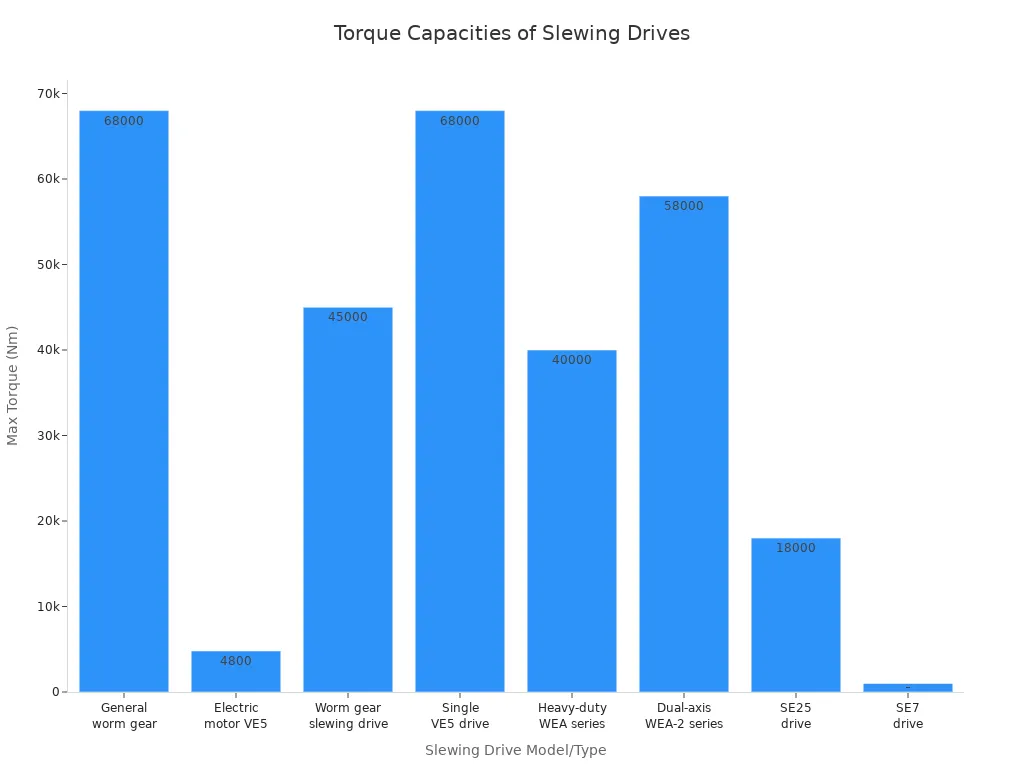

Slewing muab kev sib hloov ntawm cov khoom siv tshuab, txhawb nqa cov khoom loj nrog qhov tseeb. Cov cuab yeej hnyav, xws li cranes thiab cua turbines, tso siab rau cov kabmob siab thiab tsav tsheb. Covhydraulic slewing tsavkom ntseeg tau tias kev hloov torque.Hom load peev xwm nthuav dav ntau yam:

| Slewing Tsav Model / Hom | Torque Range (Nm) | Max Static Torque (kNm) | Daim ntawv thov |

|---|---|---|---|

| General worm iav slewing drives | 365-68,000 Nws | Mus txog 190 | Cranes, cua turbines, hnub ci trackers |

| Hluav taws xob lub cev muaj zog VE5 slewing tsav | 4,800 ib | N/A | Kab mob kis tau tus mob |

| Worm iav slewing tsav | 2,500-45,000 | 190 | 360 ° tig, siab axial load |

| Ib leeg slewing tsav VE5 | 500-68,000 | N/A | Hnub ci taug qab |

| Heavy-duty WEA series | 8,000-40,000 | N/A | Agricultural tshuab |

| Dual-axis WEA-2 series | 16,200; 19,440; 48,000; 58,000 ib | N/A | Multi-directional, muaj zog load-bearing |

| Kab iav slewing tsav SE25 | 18,000 ib | N/A | Cranes, excavators |

| Kab iav slewing tsav SE7 | 1,000 | N/A | High load, precision tswj |

Ntsiab Cai

- Slewing mechanisms pab kom du, meej kev sib hloov los ntawm kev siv bearings thiab dov cov ntsiab lus uas txhawb nqahnyav hnyavthiab txo kev sib txhuam.

- Kev thauj khoom kom raug thiab kev tswj lub zog hauv slewing tsav kom ruaj khov thiab raug txav, uas yog qhov tseem ceeb rau cov tshuab hnyav xws li cranes thiab cua turbines.

- Kev saib xyuas tsis tu ncua, suav nrog lub sijhawm lubrication thiab tshuaj xyuas, ncua lub neej ntawm slewing Cheebtsam thiab ua kom cov cuab yeej ua haujlwm zoo thiab ua haujlwm zoo.

Lub ntsiab Cheebtsam ntawm Slewing Mechanisms

Slewing Rings thiab Bearings

Slewing rings thiab bearings tsim cov pob txha ntawm slewing mechanisms. Cov khoom loj, ncig no txhawb nqa tag nrho qhov hnyav ntawm cov qauv rotating thiab pab kom du, tswj kev txav. Lub nplhaib slewing feem ntau muaj cov nplhaib sab hauv thiab sab nrauv, nrog cov ntsiab lus dov sandwiched ntawm lawv. Bearings tuav axial, radial, thiab lub sijhawm thauj khoom, ua kom ruaj khov thiab txhim khu kev lag luam. Cov lus hauv qab no qhia txog qhovcov khoom tseem ceeb thiab lawv txoj haujlwm:

| Cheebtsam | Muaj nuj nqi |

|---|---|

| Slewing Ntiv | Txhawb nqa hnyav thiab ua kom muaj kev sib hloov. |

| Cov kabmob | Tswj axial, radial, thiab lub sijhawm thauj khoom kom ruaj khov. |

| Tsav Tsheb Mechanism | Muab torque rau kev sib hloov, feem ntau ntawm hluav taws xob los yog hydraulic motors. |

Rolling Elements

Rolling ntsiab, xws li cov khoom los yog cov menyuam, txo kev sib txhuam thiab hnav hauv lub nplhaib slewing. Lawv txoj kev npaj thiab hom ncaj qha cuam tshuam rau kev ua haujlwm thiab kav ntev.Plaub-point sib cuag pob bearingsfaib cov khoom ntawm plaub lub ntsiab lus, ua kom yoog raws. Hla cov menyuam bearings, nrog rau cov menyuam teeb tsa ntawm lub kaum sab xis, muab cov khoom thauj zoo tshaj plaws thiab rigidity. Peb-kab cov menyuam bearings muab lub peev xwm siab tshaj plaws, ua rau lawv zoo tagnrho rau cov haujlwm hnyav. Qhov kev xaiv ntawm dov lub caij cuam tshuam rau lub tshuab ua haujlwm thiab lub neej ntev.

Gears thiab Tsav Systems

Gears thiabtsav systemsxa hluav taws xob los ntawm lub cev muaj zog mus rau lub nplhaib slewing. Feem ntau slewing mechanisms sivworm iav configurations, qhov twg ib tug worm ncej tsav ib perpendicular iav. Qhov kev teeb tsa no txo qhov ceev thiab nce lub zog, qhov tseem ceeb rau cov tshuab hnyav. Cov qauv tsim niaj hnub no feem ntau muaj cov cuab yeej siv tshuab ntxhua khaub ncaws, uas txhim kho cov hniav sib txuas thiab kav ntev. Dual-axis thiab dual-tsav tshuab ntxiv txhim khu lub zog thiab tswj.

Seals thiab lubrication

Cov ntsaws ruaj ruaj thiab lubrication tiv thaiv cov khoom siv sab hauv thiab xyuas kom muaj kev ua haujlwm ntev. Cov ntsaws ruaj ruaj zoo tiv thaiv cov kab mob nkag mus rau hauv cov kabmob.lubrication kom raugtxo kev sib txhuam, tiv thaiv kev sib cuag hlau-rau-hlau, thiab dissipates cua sov. Kev saib xyuas tsis tu ncua thiabadvanced lubrication technologies, zoo likhoom lubrication, ncua kev coj tus kheej lub neej thiab kev ntseeg tau. Lub tshuab lubrication zoo kuj txo cov suab nrov thiab kev co, txhawb kev ua haujlwm du.

Yuav ua li cas Slewing Mechanisms ua haujlwm

Kev sib cuam tshuam ntawm Cheebtsam rau kev sib hloov

Slewing mechanisms ua tiav kev sib hloov zoo los ntawm kev sib koom ua ke ntawm ntau yam tseem ceeb. Cov txheej txheem nthuav tawm nyob rau hauv ib ntus meej:

- Covslewing bearing zaum ntawm ob lub tshuab tseem ceeb, xws li lub hauv paus crane thiab nws rotating superstructure.

- Sab nraud quab yuam, suav nrog qhov hnyav ntawm cov khoom siv thiab cov khoom ua haujlwm, ua rau cov kabmob.

- Rolling ntsiab-pob los yog rollers-txav ntawm lub puab thiab sab rings ntawm cov kabmob.

- Cov khoom dov no faib cov ntaub ntawv thov thoob plaws lawv qhov chaw sib cuag thiab cov kev sib tw tshwj xeeb.

- Cov raceways, nrog rau lawv cov grooves optimized, txo cov kev ntxhov siab thiab xyuas kom meej txawm tias kev sib koom.

- Ob lub dov cov ntsiab lus thiab cov raceway geometry tiv taus deformation, txawm nyob rau hauv hnyav loads.

- Qhov kev tiv thaiv no tso cai rau kev sib tw, kev sib txhuam qis ntawm cov khoom sib txuas.

- Cov txheej txheem meej ntawm dov cov ntsiab lus thiab cov geometry ntawm cov raceways pab tswj kom raug.

- Raws li lub tshuab rotates, cov kabmob tsis tu ncua redistributes hloov loads kom ruaj khov.

- Cov ntaub ntawv qib siab thiab kev coj ua engineering txuas ntxiv lub neej kev pabcuam thiab ua kom ntseeg tau tias kev ua haujlwm ruaj khov nyob rau hauv ntau yam xwm txheej.

Nco tseg: Hnav thiab qaug zog sawv cev rau feem ntau hom kev ua tsis tiavhauv slewing bearings. Cov teeb meem no feem ntau tshwm sim los ntawm kev sib tsoo, kev sib txhuam, kev sib tw lubrication, lossis kev sib dhos tsis raug. Lwm yam teeb meem muaj xws li tawg, corrosion, thiab deformation. Kev tshuaj xyuas thiab tu tsis tu ncua pab tiv thaiv cov kev ua tsis tiav no thiab ua kom muaj kev nyab xeeb, txhim khu kev qha.

Load Distribution thiab Support

Slewing bearings yuav tsum tuav cov xwm txheej nyuaj thaum ua haujlwm. Cov loads no muaj xws li:

- Axial loads:Kev quab yuam ua rau perpendicular mus rau axis ntawm kev sib hloov, feem ntau tshwm sim los ntawm qhov hnyav ntawm cov khoom siv los yog kev cuam tshuam sab nraud.

- Radial loads:Cov quab yuam ua yeeb yam mus rau lub axis, xws li cov tshwm sim los ntawm cua los yog centrifugal teebmeem.

- Lub sijhawm loads:Kev sib xyaw ntawm axial thiab radial rog, feem ntau tsim los ntawm kev txav thiab qhov hnyav ntawm lub tshuab.

Load faib thoob plaws cov kabmob yog tsis tshua muaj sib xws. Qhov curvature ntawm txoj kev sib tw thiab tus naj npawb ntawm cov khoom dov cuam tshuam li cas cov khoom sib kis thoob plaws cov kabmob. Engineers optimize load faib los ntawm kev kho tus naj npawb thiab qhov loj ntawm dov cov ntsiab lus, lub kaum sab xis sib cuag, thiab cov raceway profile.

Muaj ntau txoj hauv kev engineering pab tswj kev txhawb nqa txawm tias:

- Kev lubrication kom zoo txo kev sib txhuam thiab hnav, txhawb nqa uniform load faib.

- Xaiv cov roj zoo-lithium-based, calcium-based, lossis polyurea-raws li kev ua haujlwm zoo rau kev ua haujlwm tshwj xeeb.

- Cov khoom siv ntxiv xws li molybdenum disulfide (MoS₂) txhim kho lub peev xwm thauj khoom thiab tiv thaiv hnav.

- Ua raws li kev pom zoo lubrication ncua sij hawm thiab kom muaj nuj nqis tiv thaiv kev hnav ntxov ntxov thiab tsis sib xws.

- Plaub-point contact geometrytso cai rau ib kab ntawm cov khoom txhawb nqaaxial, radial, thiab lub sijhawm thauj khoomib txhij.

- Internal clearance optimization accommodates misalignment thiab thermal expansion, tswj kev rotational raug.

- Precision manufacturing, suav nrog CNC machining thiab induction hardening, tsim cov high-quality raceways uas tiv taus dynamic loads.

- Siab tawv thiab compact tsim txo qhov system loj thiab txhawb nqa eccentric lossis offset loads zoo.

Tswv yim:Cov kabmob yooj yim tsim nrog tsawg qhov chaw tsis tsuas yog yooj yim sib dhos thiab txij nkawm tab sis kuj tseem ua rau muaj kev ua tau zoo ib yam thiab txawm tias thauj khoom.

Torque Transmission thiab Control

Torque kis tau tus mob nyob ntawm lub plawv ntawm slewing mechanism kev ua tau zoo. Covslewing iav hloov torquelos ntawm lub tshuab hluav taws xob qhov chaw-xws li hluav taws xob lossis hydraulic lub cev muaj zog-rau cov qauv rotating. Cov txheej txheem no ua rau txoj kab rov tav tig nyob ib ncig ntawm lub axis ntsug, tso cai rau qhov tseeb ntawm cov khoom hnyav.

Cov yam tseem ceeb ntawm kev sib kis thiab kev tswj lub zog muaj xws li:

- Covlub cev muaj zog generates torque, uas dhau los ntawm kev sib kis. Cov kab ke no yuav siv cov pinions, cab iav, lossis lwm hom iav.

- Lub slewing bearing tau txais kev sib kis torque, txhawb nqa axial, radial, thiab lub sijhawm thauj khoom thaum ua kom muaj kev sib hloov.

- Worm iav kis tau tus kheej muaj qhov ntsuas tus kheej, uas pab tuav cov khoom ruaj ntseg thiab tso cai rau kev tswj xyuas qhov tseeb.

- Lub slewing tsav los ua ke muaj xws li vaj tse thiab sealing system los tiv thaiv cov khoom sab hauv thiab tswj kev ua haujlwm zoo ib yam.

- Tag nrho cov khoom ua haujlwm ua ke los muab qhov tseeb, kev sib hloov ntawm kev sib hloov thiab ua kom cov khoom ruaj khov thaum lub sijhawm ua haujlwm.

| Parameter | Tus nqi / piav qhia |

|---|---|

| Slewing Tsav Hom | Spur iav slewing tsav |

| Gear Ratio | 9:1 ua |

| Rated Output Torque | ~ 37 kNm(tus qauv hnyav hnyav) |

| Rotation Center Diameter | 9 55mm |

| Tag nrho qhov siab nrog Adapter | 180 mm |

| Gear Backlash | ≤ 0.40 hli |

| Daim ntawv thov | Cov khoom siv hnyav nrog lub sijhawm tilting loj thiab hnyav hnyav |

| Tsim Flexibility | Loj slewing drives muaj nrog diameters txog 2300 mm thiab siab dua torque |

Niaj hnub nimno slewing mechanisms muab cov khoom siv hluav taws xob zoo, cov khoom siv siab heev, thiab kev tsim khoom kom xa cov kev sib kis tau zoo thiab kev tswj xyuas. Qhov no ua kom cov tshuab hnyav tuaj yeem ua haujlwm nyab xeeb thiab ua haujlwm tau zoo, txawm tias nyob rau hauv kev xav tau.

Hom thiab tswv yim xav txog

Hydraulic Slewing

Hydraulic Slewing tshuab siv cov kua dej los ua kom lub zog siab thiab du, sib npaug tswj. Cov tshuab no ua tau zoo hauv cov ntawv thov hnyav, xws li cranes thiab excavators, qhov chaw ua haujlwm tas li nyob rau hauv cov khoom tseem ceeb.Hydraulic Slewingmuaj cov tshuab ua haujlwm siab thiab txhim khu kev qha hauv cov chaw hnyav. Cov neeg ua haujlwm tau txais txiaj ntsig los ntawm kev txav mus los ntawm qhov nrawm qis, uas yog qhov tseem ceeb rau kev nqa thiab tso cov khoom hnyav.Hydraulic Slewing systemsxav tau kev koom ua ke nrog cov twj hydraulic thiab kev tswj cov kua dej, ua rau kev txhim kho thiab kev saib xyuas ntau dua li kev hloov hluav taws xob. Txawm li cas los xij, lawv muab lub zog rub zoo tshaj plaws thiab tuaj yeem ua haujlwm yam tsis muaj cua sov thaum siv txuas ntxiv. CovKev ua haujlwm ntawm Hydraulic Slewing txhim kho ntxiv hauv hybrid systems, uas txo qhov siab tshaj plaws thiab lub zog noj.

Lwm hom Slewing Mechanisms

Cov tshuab niaj hnub siv ntau hom slewing mechanism, txhua tus muaj cov yam ntxwv tshwj xeeb.Worm iav drives muab cov iav txo qis hauv qhov chaw compactthiab muaj peev xwm kaw tus kheej, uas txhim kho kev nyab xeeb. Spur iav tsav siv cov ncej sib npaug thiab cov hniav ncaj, ua rau lawv haum rau cov tsheb ciav hlau yooj yim dua.Hluav taws xob slewing mechanisms muab cov cab iav nrog slewing nplhaib bearings, xa qhov tseeb, siab-torque rotation thiab ruaj ntseg tuav txoj haujlwm.Cov lus hauv qab no qhia txog cov hom slewing bearing thiab lawv daim ntawv thov:

| Hom Slewing Bearing | Cov yam ntxwv zoo | Cov ntawv thov nyob rau hauv Modern Machinery |

|---|---|---|

| Plaub-point Sib cuag Pob Slewing Bearing | Cov qauv yooj yim, txhawb nqa bidirectional axial thiab radial rog, qee qhov kev hloov pauv lub sijhawm muaj peev xwm | Me me cranes, khoom siv tuav |

| Ob chav kab sib txawv-ntev pob | Ob kab ntawm pob, optimized load peev xwm thiab kev pab lub neej | Qhov nruab nrab qhov chaw nres nkoj machinery, stacking cranes |

| Hla Cylindrical Cov Menyuam | High overturning lub sij hawm thiab axial quab yuam muaj peev xwm, siab rotation precision | Cov chaw nres nkoj loj cranes, choj cranes |

| Peb-kab Cylindrical Cov Menyuam | Cov cheeb tsam loj, txhawb nqa loj axial, radial, thiab overturning moments | Ultra-loj, heavy-duty port machinery |

Kev tu thiab tu

Kev saib xyuas kom zoo ua kom lub neej ntev thiab kev cia siab ntawm slewing mechanisms.Cov neeg ua haujlwm yuav tsum tshuaj xyuas bolts ua ntej txhua qhov haujlwm thiab tom qab thawj 100 teev ua haujlwmTom qab ntawd 300 teev, thiab txhua 500 teev tom qab ntawd.Lub sijhawm lubrication yog los ntawm txhua txhua 200 mus rau 500 teev, nyob ntawm load thiab ib puag ncig. Hauv cov xwm txheej hnyav, xws li cov av noo siab lossis plua plav, lub voj voog lubrication yuav tsum tau luv. Kev tshuaj xyuas tsis tu ncua pab tshawb xyuas qhov hnav, kev puas tsuaj, lossis kev sib kis ntxov. Ntxuav, kho lubrication kom raug, thiab hloov raws sij hawm ntawm cov khoom hnav kom tiv thaiv kev tshem tawm ntau dhau, roj to, thiab overheating.

Cov ntawv thov siv

Slewing mechanisms ua lub luag haujlwm tseem ceeb hauv ntau qhov kev lag luam.Kev tsim kho thiab kev lag luam tshuab cia siab rau lawv rau 360-degree kev sib hloov thiab kev txhawb nqa hnyav. Cov ntawv thov uas muaj xws li:

- Excavators thiab cranes rau nqa thiab tuav cov khoom

- Forestry machinery thiab forklifts

- Mining rigs thiab thawv tsheb thauj khoom

- High-altitude tsheb thiab industrial robots

Cov txheej txheem no kuj tshwm sim nyob rau hauv marine, renewable zog, aerospace, thiab automation sectors, txhawb kom meej zog thiab stability.

Slewing mechanisms pab kom meej, hnyav-lub luag haujlwm tig thoob plaws kev lag luam, los ntawm cranes mus rau cua turbines. Lawv advanced designs, xws lipeb-kab cov menyuam thiab hla cov menyuam bearings, txhawb nqa complex loads thiab xyuas kom meej kev ua tau zoo.Kev saib xyuas tsis tu ncua, suav nrog Hydraulic Slewing systems, maximizes khoom lifespan thiab kev nyab xeeb kev khiav hauj lwm. Kev tsim kho tshiab tsis tu ncua txuas ntxiv tsav kev ua haujlwm tau zoo thiab raug.

FAQ

Lub luag haujlwm tseem ceeb ntawm slewing tsav yog dab tsi?

A slewing tsavenables tswj rotational txav ntawm ob lub tshuab qhov chaw. Nws txhawb nqa hnyav thiab ua kom muaj qhov tseeb ntawm cov khoom siv hauv kev lag luam.

Ntau npaum li cas cov neeg ua haujlwm yuav tsum lubricate slewing bearings?

Cov neeg ua haujlwm yuav tsum lubricate slewing bearings txhua 200 mus rau 500 teev. Ib puag ncig hnyav yuav xav tau lubrication ntau zaus kom tswj tau qhov ua tau zoo.

Puas tuaj yeem slewing mechanisms tuav ob qho tib si axial thiab radial loads?

Yog lawm. Slewing mechanisms txhawb nqa axial, radial, thiab lub sijhawm thauj khoom. Lawv tsim faib cov zog no kom zoo, ua kom muaj kev ruaj ntseg thiab ua haujlwm ntev.

Post lub sij hawm: Lub Xya hli ntuj-25-2025