Kayan spur yana fasalta madaidaiciyar hakora kuma yana jujjuyawa akan layi daya. Gilashin pinion, yawanci ƙarami a cikin nau'i-nau'i, yana haɗa tare da kayan motsa jiki don watsa motsi. Tare, spur da pinion gears suna canja iko da kyau a cikin masana'antu da yawa, gami da kera motoci, sararin samaniya, da aikace-aikacen Slewing na'ura mai ba da hanya tsakanin hanyoyin sadarwa.

Key Takeaways

- Spur da pinion gears suna aiki tare don canja wurin wutar lantarki da kyau tsakanin igiyoyi masu kama da juna, tare da pinion yawanci shine ƙaramin kayan tuki.

- Wadannan gears suna ba da sosaibabban inganci, sau da yawa sama da 98%, yana sanya su manufa don injunan da ke buƙatar abin dogaro da ingantaccen sarrafa motsi.

- Spur da pinion gears ana amfani dasu sosai a masana'antu da yawa, gami da kera motoci, sararin samaniya, dana'ura mai aiki da karfin ruwa slewing, saboda dorewarsu da sauƙin kulawa.

Yadda Spur da Pinion Gears ke Aiki

Makanikai na asali

Spur da pinion gears suna aiki akan ƙa'idodin injina masu sauƙi amma daidai. Waɗannan ginshiƙan suna watsa motsin jujjuyawar tsakanin sanduna masu kama da juna, suna riƙe da madaidaicin rabon gudu. Bayanan martabar haƙori mai ƙima, siffa mai lanƙwasa, yana tabbatar da ƙulli mai santsi da tsayin daka yayin aiki.

- Thefilin wasada'irar hasashe ce da ta ratsa ta inda hakoran gear biyu ke shiga. Wannan batu, wanda ake kira filin wasa, shine inda kayan aikin ke canja wurin motsi da inganci.

- Ayyukan haɗin gwiwa yana nufin cewa yayin da haƙoran gear guda ɗaya ke tura wani, haƙoran da ke tukawa yana motsawa daidai gwargwado, yana daidaita saurin gudu.

- Matsakaicin gear ya dogara da adadin hakora ko diamita na da'irar farar. Babban kayan aiki da aka haɗa tare da ƙaramin pinion yana ƙaruwa da ƙarfi amma yana rage gudu.

- Mabuɗin sharuddan sun haɗa da:

- Module(Auni na girman hakori)

- Girman diamita(ma'aunin sarki)

- kusurwar matsa lamba(yawanci 20°)

- Rabon lamba(matsakaicin adadin hakora a hulɗa)

Lura:Matsakaicin lamba yana taimakawa raba kaya tsakanin hakora, yana sa tsarin kayan aiki ya fi karfi da santsi.

Zaɓin kayan abu yana taka muhimmiyar rawa a aikin kayan aiki. Karfe, tagulla, da thermoplastics kamar nailan ko acetal zabin gama gari ne. Karfe yana ba da ƙarfi da karko, yayin da robobi ke rage hayaniya da tsayayya da lalata. Bronze da bakin karfe suna aiki da kyau a cikin rigar ko mahalli masu tsauri. Injiniya sukan yi amfani da sumaganin zafi kamar carburizing ko induction hardeningdon ƙara taurin saman da kuma tsawaita rayuwar kayan aiki.

Saitin spur da pinion gear na yau da kullun yana amfani da pinion azaman kayan tuƙi. Haƙoranta sun haɗa da na kayan aikin spur,canja wurin motsi da ƙarfi. Madaidaicin hakora na kayan motsa jiki suna ba da izinin isar da wutar lantarki mai inganci tsakanin igiyoyi masu kama da juna.

Motsi da Canja wurin Wuta

Ma'amala tsakanin spur da hakora gear pinion daidai ne kuma mai inganci. Haƙoran haƙora suna haɗawa a da'irorin su, inda canjin motsi da jujjuyawar ke faruwa. Yayin da pinion ke jujjuyawa, haƙoransa suna matsawa haƙoran spur gear, yana haifar da jujjuyawar kayan. Wurin tuntuɓar yana motsawa tare dalayin aiki, Layin hasashe wanda ke jagorantar watsa ƙarfin tsakanin gears.

- Haƙoran gear suna shiga cikin da'irar farar, suna canja wurin motsi da ƙarfi.

- Wurin tuntuɓar yana tafiya tare da layin aiki, yana tabbatar da canja wurin ƙarfi mai santsi.

- Haɓaka bayanan martaba na haƙori suna rage girman tasirin tasiri kuma suna ba da damar tsayawa tsayin daka.

- Abubuwan Geometric kamar diamita na da'irar farar, kusurwar matsa lamba, da koma baya suna tasiri yadda raƙuman ginshiƙan ya daidaita.

- Backlash, ƙaramin rata tsakanin hakora, yana hana cunkoso kuma yana ba da damar haɓakar thermal.

- Kusurwar meshing tana rinjayar gogayya da hayaniya yayin aiki.

- Waɗannan fasalulluka suna ba da damar pinion don fitar da kayan spur tare da inganci da aminci.

Matsakaicin gear, wanda aka ayyana azaman adadin haƙora akan kayan aikin da aka raba ta lamba akan kayan tuƙi, kai tsaye yana rinjayar saurin gudu da juzu'i. Misali, a2: 1 rabon kayayana nufin kayan aikin da ake tuƙi yana juyawa a rabin gudun pinion amma yana ba da juzu'i sau biyu. Wannan dangantakar tana bawa injiniyoyi damar tsara tsarin kayan aiki waɗanda suka dace da takamaiman bukatun aiki.

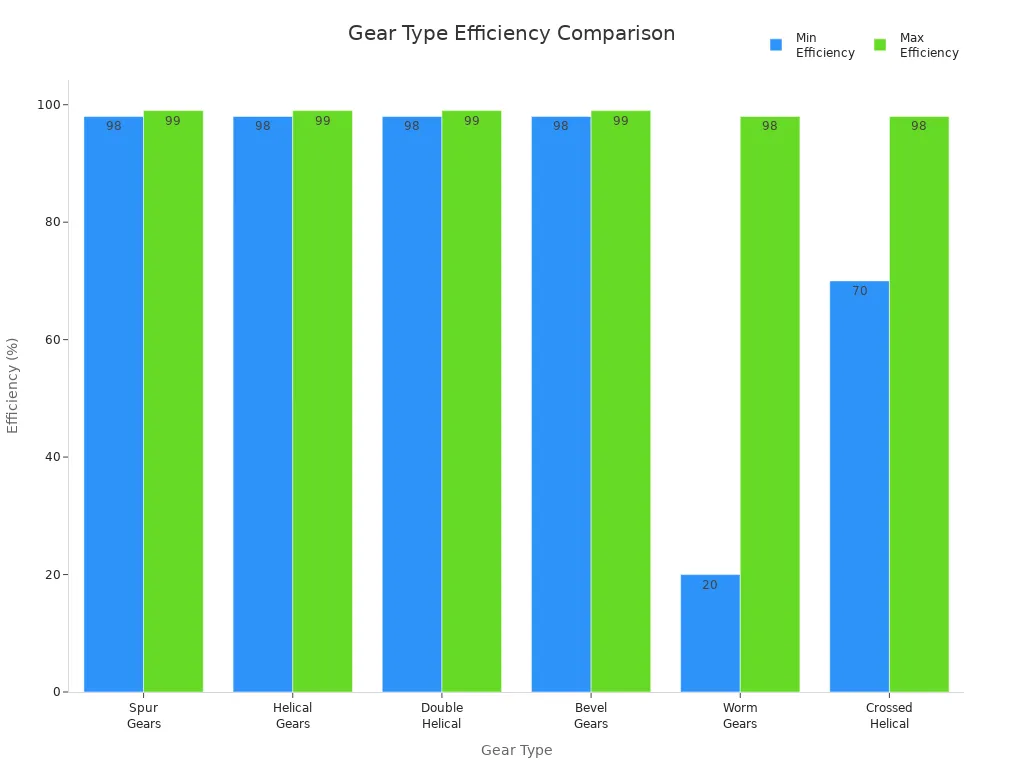

| Nau'in Gear | Tsawon inganci | Mabuɗin Mahimmanci akan inganci da Asara |

|---|---|---|

| Spur Gears | 98-99% | Babban inganci; ƙarancin hasara musamman daga gogayyawar haƙori da maƙarƙashiya |

| Helical Gears | 98-99% | Ƙananan ƙasa fiye da spur saboda matsawar axial da aikin zamiya |

| Biyu Helical | 98-99% | Kwatanta da spur da helical gears |

| Bevel Gears | 98-99% | Babban inganci amma ƙasa da spur saboda aikin zamiya |

| Gears na tsutsa | 20-98% | Mahimmanci ƙananan inganci, dogara sosai akan rabon kaya da yanayi |

| Ketare Helical | 70-98% | Ƙananan inganci saboda zamewa da hadadden haɗin haƙori |

Spur da pinion gears sun fito ne don ingantaccen ingancin su, yawanci suna kaiwa 98-99%. Wannan ya sa su dace don aikace-aikace inda ƙananan asarar makamashi ke da mahimmanci. Duk da haka, spur gears suna da yawasamar da karin amo fiye da helical gearssaboda hakoransu suna shiga ba zato ba tsammani, suna sakin kuzari da sauri kuma suna haifar da girgiza. Gears na Helical, tare da hakora masu kusurwa, suna aiki cikin nutsuwa amma sun fi rikitarwa don kera.

Kulawa yana da mahimmanci don ingantaccen aiki na kayan aiki. Abubuwan gama gari sun haɗa dalalacewa, rashin daidaituwa, da rashin isasshen man shafawa. Dubawa akai-akai da mai da kyau yana taimakawa hana matsaloli irin su pitting, spalling, da abrasive lalacewa. Zaɓin kayan da ya dace da kuma kiyaye daidaitattun daidaitawa yana ƙara tsawon rayuwar spur da pinion gears, tabbatar da santsi da ingantaccen canja wurin wutar lantarki a cikin nau'ikan inji.

Mabuɗin Features da Bambance-bambance

Spur Gear Design

Spur gears sun yi fice don sumadaidaicin hakora, waɗanda ke tafiya a layi daya da axis gear. Wannan zane yana ba da damar yin hulɗa kai tsaye tsakanin saman haƙori, yana haifar dababban inganci - sau da yawa sama da 98%. Spur gears suna watsa motsin jujjuyawar tsakanin sanduna masu kama da juna kuma suna da siffa mai sauƙi. Yawancin kayan motsa jiki na waje ne, tare da hakora a gefen waje, suna haifar da kayan motsa jiki don juyawa ta gaba. Gears spur na ciki, tare da hakora a ciki, suna ba da damar kusancin tazarar magudanar ruwa da mafi girman juzu'i amma yana buƙatar ƙarin hadaddun masana'anta.

| Siffar | Spur Gears | Sauran Nau'in Gear (Taƙaice) |

|---|---|---|

| Zane Haƙori | Madaidaicin hakora masu layi daya da axis gear | Helical: hakora masu kusurwa; Bevel: conical; tsutsa: dunƙule-kamar; Planetary: Gears da yawa na duniya |

| Shaft Orientation | Wuraren layi ɗaya | Helical: layi daya; Bevel: intersecting; Tsutsa: mara daidaituwa; Planetary: layi daya/coaxial |

| inganci | Babban (98% ko fiye) | Helical: ƙananan ƙananan; Bevel: matsakaici; tsutsa: ƙasa; Planetary: babba |

| Matsayin Surutu | Surutu a babban gudu | Helical: ya fi shuru; Bevel: matsakaici; Tsutsa: shiru; Planetary: matsakaici |

| Complexity & Farashi | Mai sauƙi, ƙananan farashi | Helical: mai rikitarwa; Bevel: matsakaici; tsutsa: hadaddun; Planetary: mai matukar rikitarwa |

Adadin hakora akan kayan spur yana shafar rabon kaya, santsi, da rarraba kaya. Injiniya sukan zaɓaakalla hakora 18don daidaitattun ƙira don guje wa raguwa da tabbatar da ingantaccen aiki.

Halayen Pinion Gear

Gilashin pinion yawanci ƙananan kaya ne a cikin biyu. Matsayinsu a cikin jirgin ƙasa na gear yana ƙayyade fa'idar injinan tsarin da fitarwar ƙarfi. Lokacin amfani da tsarin rack-and-pinion, daƘarfin pinion da sauri kai tsaye suna tasiri karfi da motsi na tara. A cikin jirgin ƙasa gears,m hawa na pinion gears taimaka rarraba lodi a ko'ina, inganta karko da rage damuwa. Ci gaban kayan aiki, kamarcarbon fiber-ƙarfafa polymers, sun ƙara ƙarfin aiki na pinion, yana ba su damar yin aiki mai kyau ko da a ƙarƙashin yanayi masu kalubale.

Tukwici: Zaɓin kayan da ya dace da ƙididdige haƙora don kayan aikin pinion na iya tsawaita rayuwar sa da haɓaka aikin tsarin.

Spur Gear vs. Pinion Gear

Spur gears da pinion gears suna raba tsarin masana'antu iri ɗaya, duka suna amfana dagasamarwa mai sauƙi da tsada. Spur gears suna aiki a matsayin babban direba ko kayan aiki, yayin da gears na pinion sukan yi aiki azaman shigarwa ko fitarwa, musamman a cikin rak-da-pinion ko tsarin duniya. Spur gears yawanci suna ɗaukar watsa wutar lantarki, yayin da pinion gears na iya canza motsin juyawa zuwa motsi na layi. Dukansu nau'ikan yanzu suna amfani da hanyoyin masana'antu masu dorewa, kamarƙirƙira siffa ta kusakumakayan sake yin amfani da su, don rage tasirin muhalli. Bambance-bambancen girman su, aiki, da aikace-aikacen suna sa kowane mahimmanci a cikin tsarin injina.

Aikace-aikace masu amfani da na'ura mai aiki da karfin ruwa Slewing

Amfanin yau da kullun da Misalai

Spur da pinion gears suna bayyana a yawancin samfuran yau da kullunda injunan masana'antu. Mutane suna samun waɗannan kayan a cikin watsa mota, tsarin tuƙi, har ma da kekuna. A cikin gidaje, injin wanki, masu haɗawa, da agogo sun dogara da kayan motsa jiki don aiki mai sauƙi. Pinion gears suna taka muhimmiyar rawa a cikirack da pinion tuƙi, Taimakawa direbobi sarrafa motoci da daidaito. Masana'antu suna amfani da waɗannan ginshiƙan a cikin bel ɗin jigilar kaya, famfo, da injunan tattara kaya don motsa samfuran da inganci.

| Nau'in Masana'antu / Injiniyoyi | Aikace-aikace masu dacewa na Spur da Pinion Gears |

|---|---|

| Motoci | Rage Gear, tsarin tuƙi, rollers na hanya |

| Injin Masana'antu | Akwatunan Gear, masu jigilar kaya, famfo, compressors, kayan aikin inji |

| Jirgin sama | Gudanar da jirgin sama, injinan jirgin sama, kayan saukarwa |

| Samar da Wutar Lantarki | Injin turbin iska, tashoshin wutar lantarki |

| Masana'antar Yadi | Kadi, saka, injin rini |

| Kayayyakin Mabukaci | Agogo, firintoci, kayan aikin wuta |

| Kayan Aikin Gida | Injin wanki, blenders, bushewa |

| Robotics da Automation | Injin CNC, hanyoyin servo |

| Motoci Masu Karancin Sauri & Kayan Aiki | Kekuna, kilns, ƙwallo |

| Injiniyoyin actuators | Rack da pinion tsarin |

Tsarin Slewing Hydraulicamfani da spur da pinion gears don juya manyan kayan aiki kamar cranes da excavators. Waɗannan tsarin suna jujjuya wutar lantarki ta injin hydraulic zuwa motsi mai sarrafawa, yana sauƙaƙa ɗagawa da juya manyan kaya. Them zane of Jirgin ruwa na hydraulic Slewingdamar dontoshe-da-play shigarwa, adana lokaci yayin taro.

Muhimmancin Injiniya da Kayan aiki

Spur da pinion gears suna tallafawa ainihin ayyukan injina da yawa. Suna samar da babban inganci, sau da yawa kaihar zuwa 98%, wanda ke rage asarar makamashi kuma yana sa kayan aiki su yi aiki lafiya. A cikin aikace-aikacen Slewing na'ura mai ba da hanya tsakanin hanyoyin sadarwa, waɗannan ginshiƙan suna tabbatar da daidaitaccen juyi da jujjuyawar juzu'i, har ma da nauyi mai nauyi. Gidajen da aka rufe na Hydraulic Slewing yana ba da kariya ga turɓaya da ruwa, yana mai da su abin dogaro a cikin matsanancin yanayi.

Masu kera suna zabar kayan spur da pinion gears don dorewarsu da sauƙin kulawa. Na'urar Slewing na'ura mai aiki da karfin ruwa galibi tana amfani da abubuwa masu ƙarfi kamar ƙarfe ko bakin karfe don ɗaukar ayyuka masu wahala. Waɗannan injina zasu iya aiki tare da injunan ruwa ɗaya ko biyu, suna ba da sassauci ga injuna daban-daban. Injiniyoyi suna daraja Slewing na'ura mai ba da hanya tsakanin hanyoyin sadarwa don iyawar sa na isar da hanzari cikin sauri da babban juzu'i a cikin ƙaramin sarari.

Kasuwar duniya don injuna masu amfani da kayan spur da pinion gears babba ne. A shekarar 2024,sama da miliyan 15 spur gear units aka sayar, tare da bangaren kera motoci a matsayin babban mai amfani.Fasahar Slewing Hydraulicyana ci gaba da girma cikin mahimmanci yayin da masana'antu ke buƙatar ƙarin ingantaccen kayan aiki da abin dogaro.

Spur gears suna nuna madaidaiciyar hakorada canja wurin iko tsakanin raƙuman layi ɗaya.The pinion, ko da yaushe da karami kaya, meshes tare da kayan spur don sarrafa saurin gudu da juzu'i.

- Spur da pinion gears suna bayarwababban inganci, amintacce, da daidaitoa cikin injuna kamar akwatunan gear, robotics, da motoci.

- Injiniyoyin suna tsammanin ci gaba da haɓakawa tare dakayan nauyi da ci-gaba masana'antu, tabbatar da waɗannan kayan aikin sun kasance masu mahimmanci a fasaha na gaba.

FAQ

Menene babban bambanci tsakanin abin spur gear da pinion gear?

Kayan spur na iya zama kowane girman, yayin da kayan aikin pinion koyaushe shine ƙarami a cikin biyun. Pinion yawanci yana motsa kayan spur.

Me yasa injiniyoyi ke zabar spur da pinion gears don injuna?

Injiniyoyi suna zaɓar kayan ƙwanƙwasa spur da pinion gears don babban inganci, ƙira mai sauƙi, da amintaccen canjin wutar lantarki. Waɗannan kayan aikin suna aiki da kyau a cikin injina da yawa kuma suna buƙatar kulawa kaɗan.

Za a iya spur da pinion gears iya ɗaukar nauyi mai nauyi?

Ee. Spur da pinion gears, musamman waɗanda aka yi daga abubuwa masu ƙarfi kamar ƙarfe, na iyarike kaya masu nauyia cikin kayan aiki irin su cranes, excavators, da akwatunan gear masana'antu.

Lokacin aikawa: Yuli-25-2025